Recycling and energy-saving drying room

A technology of drying room and oven, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of affecting the efficiency of processing, unfavorable energy saving, and more electric energy, so as to reduce processing cost, benefit production efficiency, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

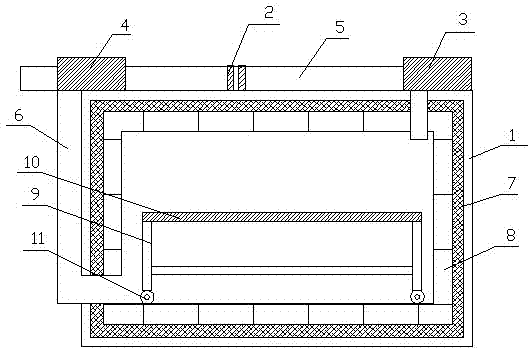

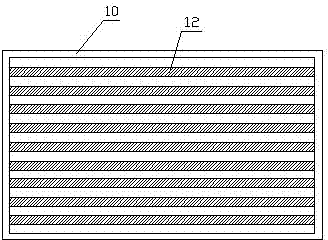

[0015] A recycling energy-saving drying room, comprising an oven 1, a fan 2, a first heat exchanger 3, and a second heat exchanger 4, such as figure 1 , the oven 1 is provided with a drying inner chamber, the top of the oven 1 is provided with an air inlet pipe 5, and the air inlet pipe 5 is sequentially connected to the second heat exchanger 4, the first heat exchanger 3, and the drying inner chamber, and the second heat exchanger A fan 2 is provided in the air inlet duct 5 between the device 4 and the first heat exchanger 3, and an exhaust port is provided on the side of the oven 1, and the exhaust port is connected with a return air duct 6, and the return air duct 6 is connected with the second heat exchanger. Another fluid inlet of the heater 4, an insulation layer is provided in the oven 1, the insulation layer adopts insulation brick 8 and insulation cotton 7 double-layer insulation, the inner layer of the insulation layer adopts insulation brick 8, and there is a Insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com