Light path system of trace gas sensor and air chamber

A trace gas, optical path system technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as difficult to meet the requirements of online testing, unrealistic, and achieve the effect of compact structure, reduced volume, and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

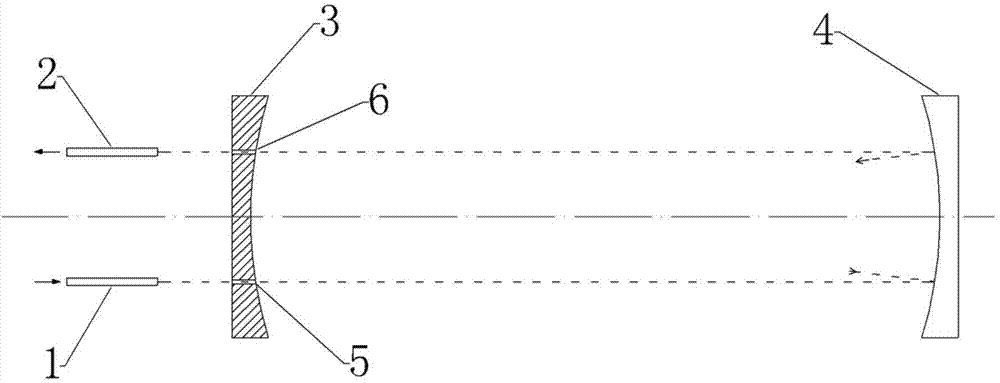

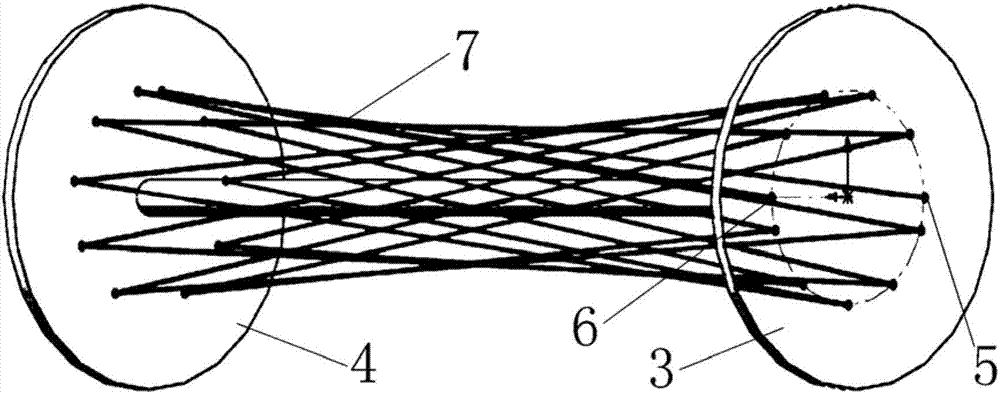

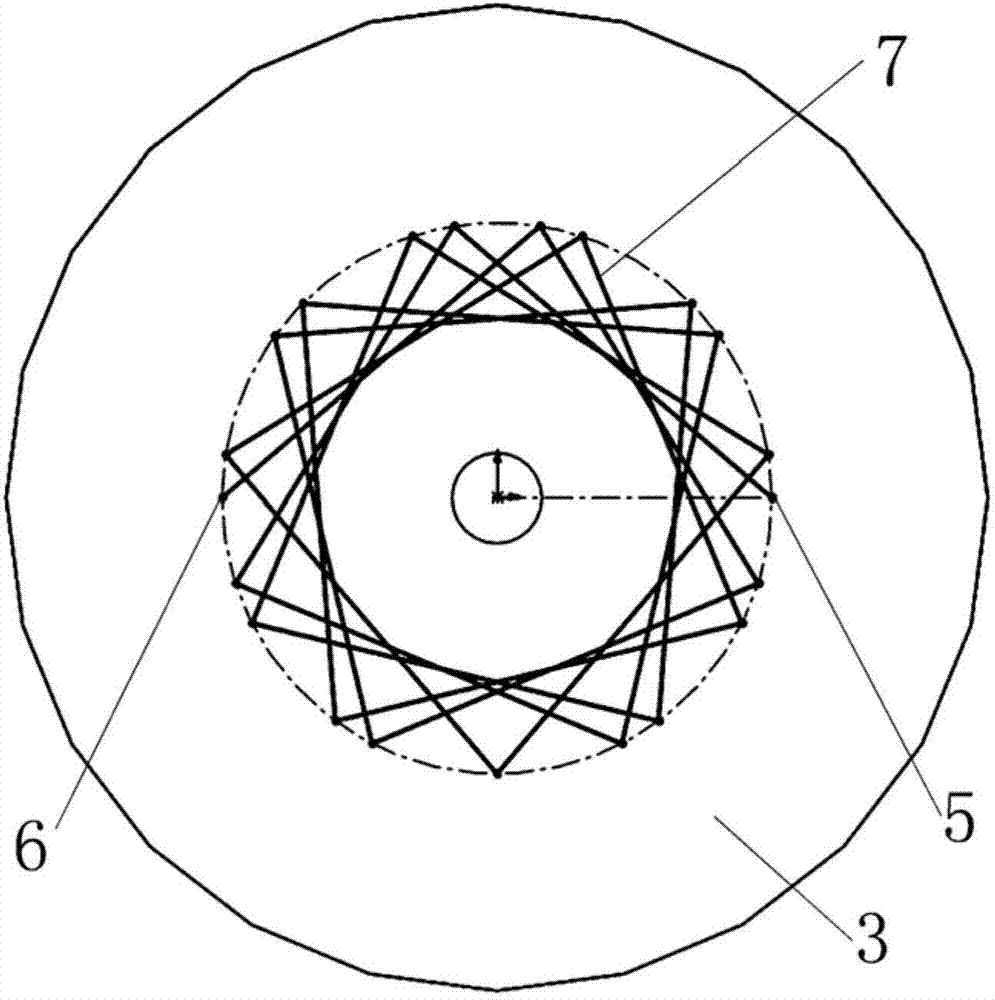

[0024] The trace gas sensor optical path system of this embodiment, such as figure 1 As shown, it includes an incident fiber collimator 1, an outgoing fiber collimator 2, a front reflector 3 and a rear reflector 4, and the front reflector 3 and the rear reflector 4 are concave spherical reflectors, and both Coated with a high-reflectivity film layer, and the concave spherical surface of the front reflector 3 and the rear reflector 4 are opposite and arranged on the same optical axis; the mirror surface of the front reflector 3 is provided with two parallel through holes, respectively for incident Through hole 5 and exit through hole 6, described incident through hole 5 and exit through hole 6 are arranged symmetrically with the optical axis of front reflector 3; Described incident fiber collimator 1, exit fiber collimator 2 are respectively The incident through hole 5 and the exit through hole 6 are coaxial, and are arranged on the outside of the front reflector 3 away from th...

Embodiment 2

[0027] A kind of trace gas sensor gas chamber of the present embodiment, such as Figure 5 As shown, it includes an absorption chamber 12 for gas absorption formed by the front end face 8, the rear end face 9 and the side wall 11. The front end face 8 and the rear end face 9 are respectively provided with A coaxial shaft hole, a front reflector 3 and a rear reflector 4 are respectively installed in the shaft hole, and the front reflector 3 and the rear reflector 4 are circular reflectors with a concave spherical surface, and the front reflector 3 and the rear reflector 4 are spherical reflectors. The concave spherical surface of the rear reflector 4 is opposite (the concave spherical surfaces are all facing the absorption chamber) and arranged on the same optical axis; the mirror surface of the front reflector 3 is provided with two parallel through holes, which are respectively the incident through hole 5 and the outgoing through hole. Holes 6, the incident through hole 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com