Ultra-thin surface light source device

A light source device and surface light source technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of inability to use display devices and the thickness of light guide plates, and achieve the effect of being conducive to thinning and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

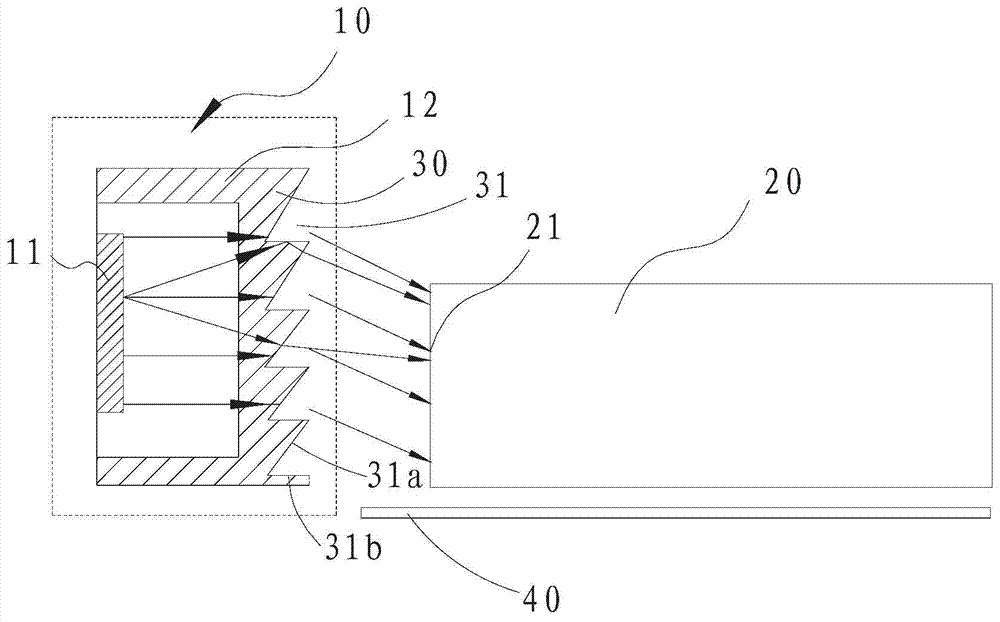

[0022] refer to figure 1 The ultra-thin surface light source device of the present invention includes an LED light source 10 and a light guide plate 20. The LED light source 10 includes a light-emitting chip 11 at the base and a transparent sealant 12 that seals the light-emitting chip 11. The light-incident side of the LED light source 10 and the light guide plate 20 21 opposite to each other, a polarizer 30 parallel to the light incident side 21 of the light guide plate 20 for projecting the light emitted by the light-emitting chip 11 toward the light guide plate 20 is provided between the light emitting chip 11 and the light guide plate 20 .

[0023] Specifically, the surface of the polarizer 30 opposite to the light guide plate 20 (that is, the surface facing the light incident side 21 in the figure) is provided with a plurality of sawtooth grooves 31 arranged longitudinally, and each sawtooth groove 31 includes an upper upper sawtooth surface 31a and the lower serrated su...

Embodiment 2

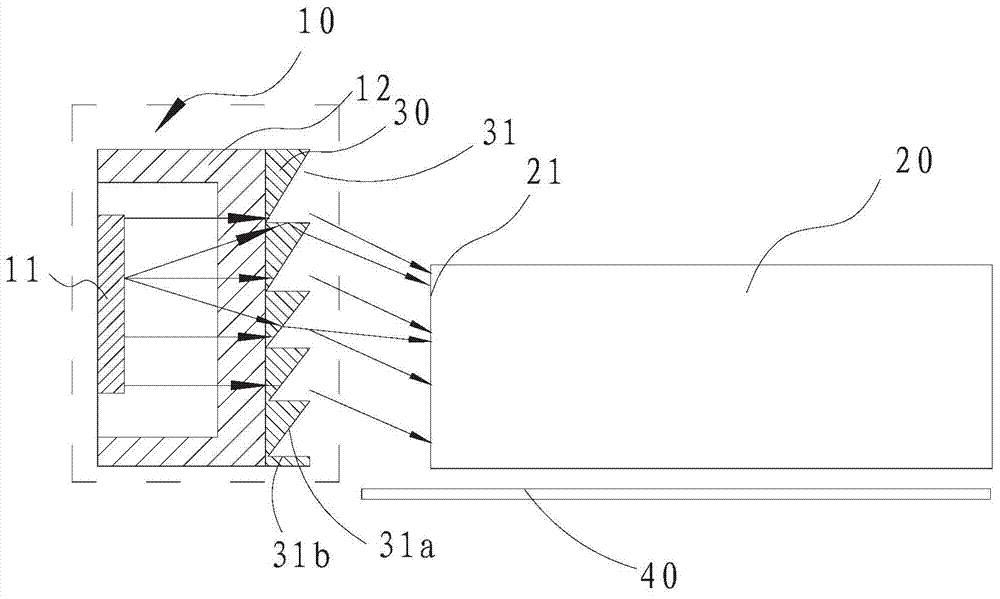

[0027] Such as figure 2 As shown, the only difference between this embodiment and Embodiment 1 is that the polarizer 30 is fixed on the sealant 12 and is in close contact with the outer surface of the sealant 12 . The polarizer 30 is specifically an optical film, and can be specifically arranged on the outer surface of the glue seal 12 by pasting.

Embodiment 3

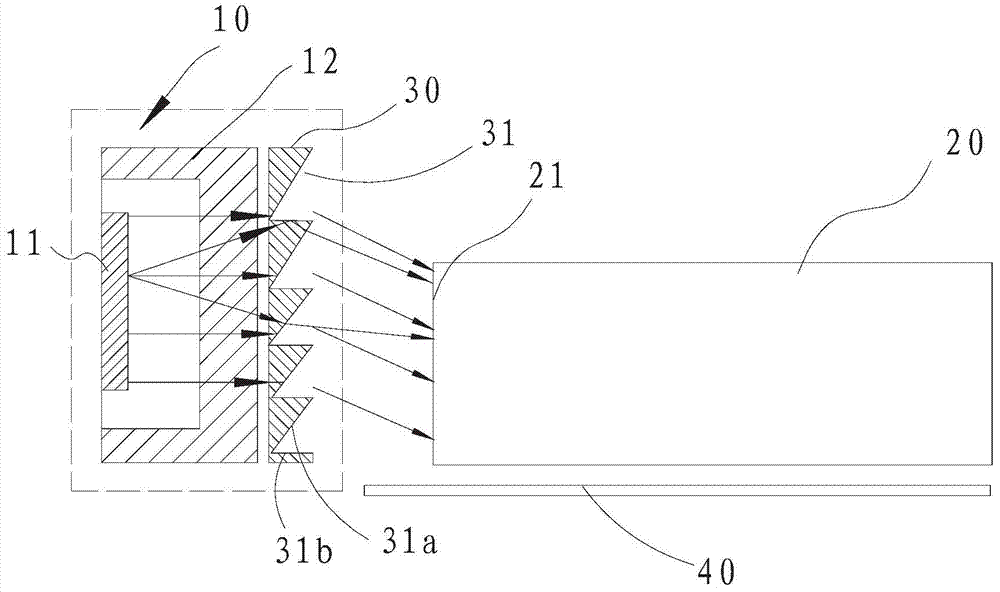

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the polarizer 30 is not in contact with the sealant 12 , but is arranged at intervals. Specifically, the polarizer 30 may be fixed on a corresponding structure of the display device, such as a plastic frame, an iron frame, and the like.

[0030] In the present invention, by setting the polarizer 30 between the light-emitting chip 11 and the light guide plate 20, the light emitted by the LED light source can be well controlled to be deflected within a certain angle range, and the light can be made without increasing the thickness of the light guide plate. All of them enter the light guide plate through the light incident side, which improves the utilization rate of light and is beneficial to the further thinning of the light guide plate and the surface light source device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com