Induction furnace water temperature constant automatic control system and method

An automatic control system and constant water temperature technology, which is applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve the problems that the water temperature system cannot be automatically controlled, the service life of the heating furnace is affected, and the cooling effect of the furnace shell is not good. , to achieve the effect of automatic control of the induction furnace water temperature, which is conducive to large-scale popularization and use, and has a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

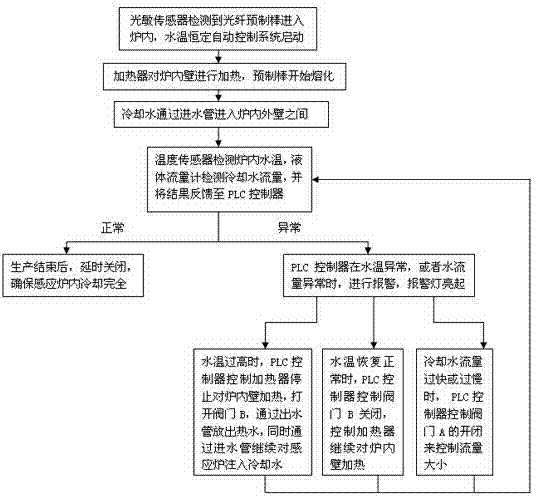

[0037] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

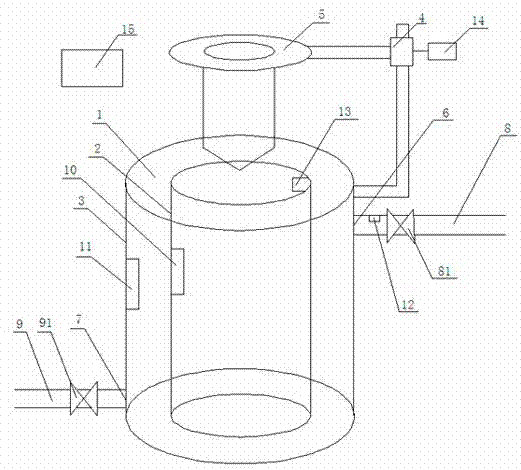

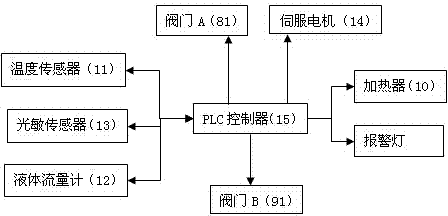

[0038] The present invention discloses an automatic control system for constant water temperature of an induction furnace. The system includes an induction furnace body 1. The induction furnace body 1 includes an outer cylinder 3 and an inner cylinder 2 embedded in the outer cylinder 3. The specific structure is as follows:

[0039] A chuck 5 is fixed directly above the induction furnace body 1 through a rod feeder 4, one end of the rod feeder 4 is fixedly connected to the chuck 5, the other end of the rod feeder 4 is fixedly connected to the outer wall of the outer cylinder 3, and the rod feeder 4 and The chuck 5 is a conventional technical structure in the technical field, so it will not be repeated here. The chuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com