Automatic water adding device based on microwave online moisture detector and control system thereof

A technology of automatic water addition and control system, which is applied in control/adjustment system, use of microwave to test moisture content, non-electric variable control, etc. It can solve the problems of system water addition fluctuation, water addition fluctuation, and large moisture content of the mixture, so as to achieve stable operation of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

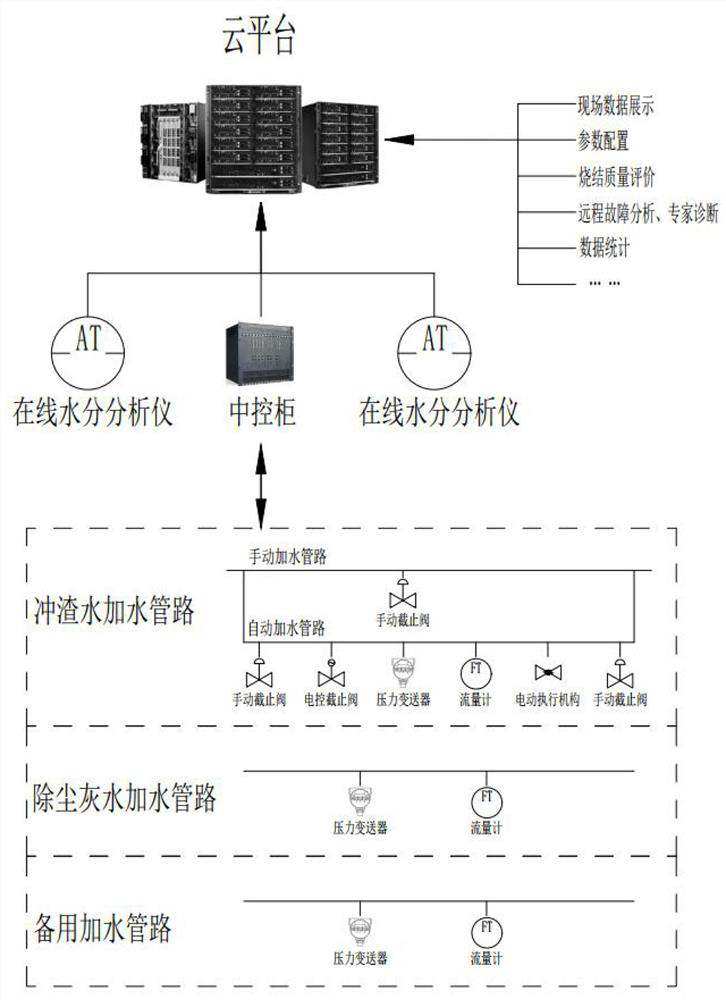

[0050] Example 1, such as figure 1 As shown, the automatic water adding device based on the microwave online moisture detector includes a central control cabinet, two online moisture detectors, water adding pipelines, and a cloud platform. The central control cabinet is connected to the online moisture detector and the water adding pipeline. The central control cabinet passes The network transmits the data to the cloud platform.

[0051] The cloud platform has functions such as data display, data statistical analysis, fault warning, remote fault analysis, expert diagnosis, sintering quality evaluation, etc., and has a PC terminal and a mobile phone APP terminal.

[0052] The moisture detectors are respectively installed on the feed belt and discharge belt of the first mixing drum of the sintering mixing line, on the discharging belt of the second mixing drum of the sintering mixing line, and the moisture detector on the feeding belt of the first mixing drum The moisture detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com