Galvanized steel sheet and manufacturing method therefor

一种热浸镀锌钢板、热浸镀锌的技术,应用在热浸镀工艺、制造工具、化学仪器和方法等方向,能够解决Si和Mn氧化、基材钢板延展性低、热浸镀锌层剥离等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

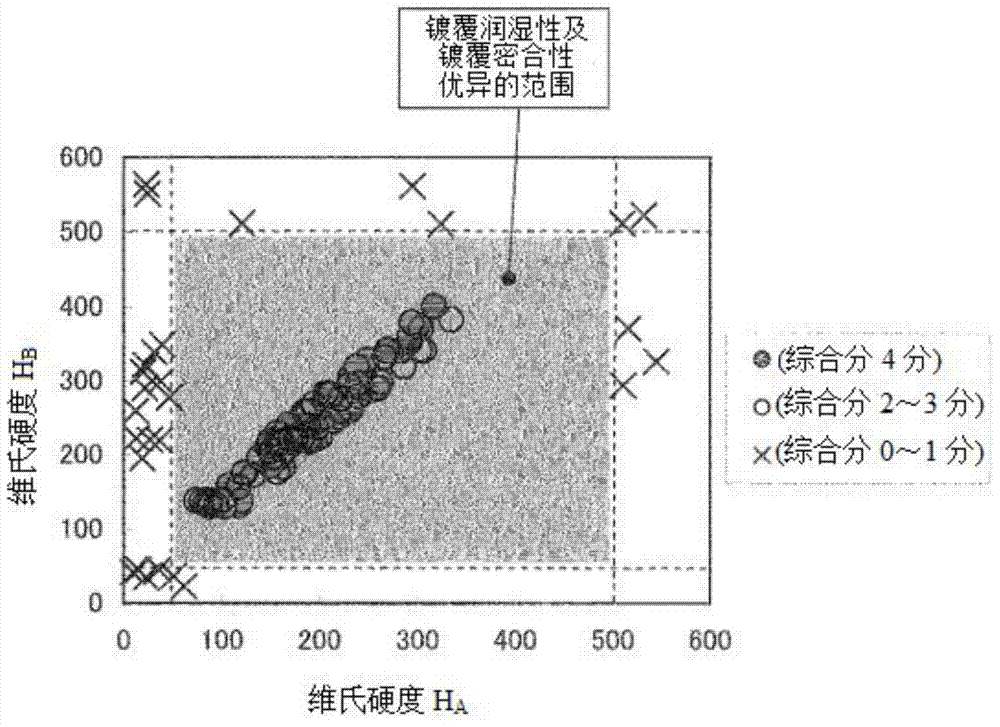

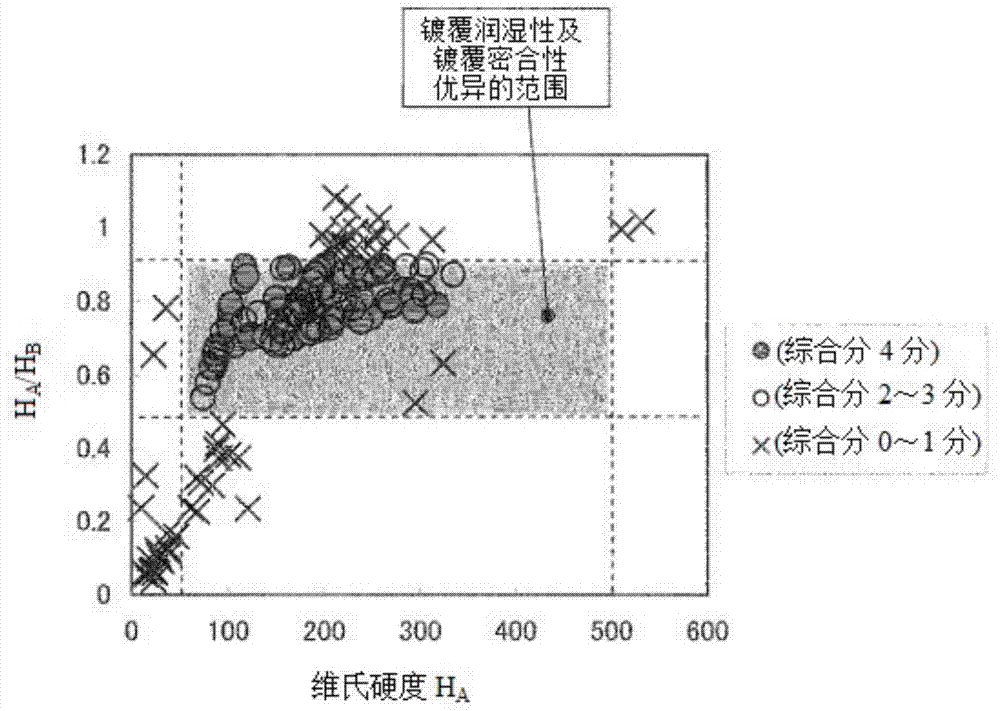

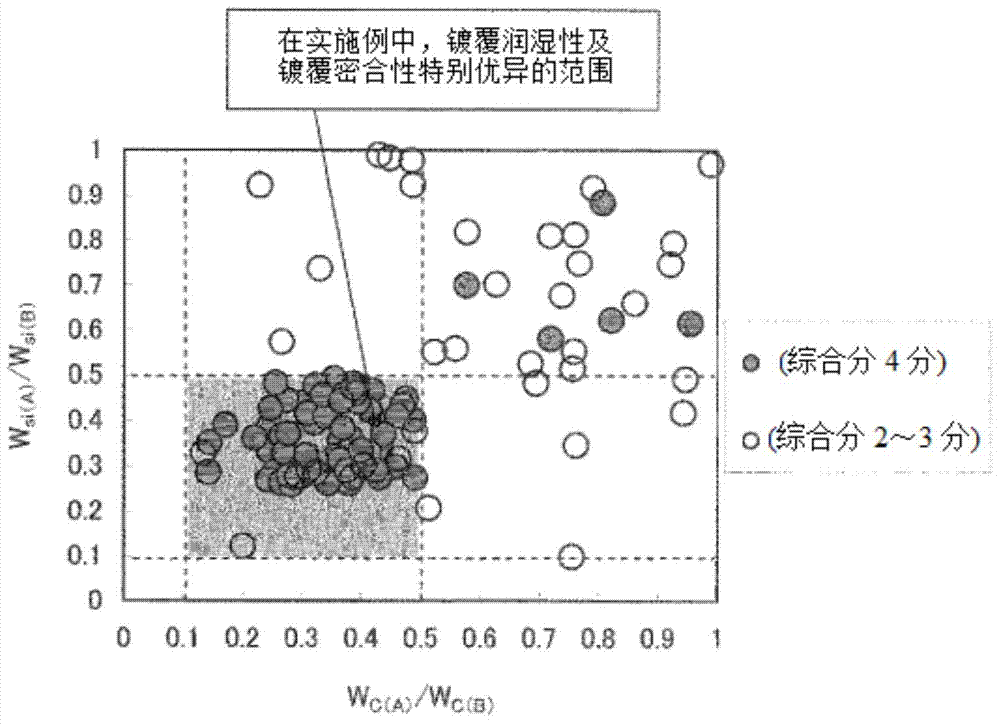

[0215] Next, examples (examples and comparative examples) of the present invention will be specifically described.

[0216] Cold-rolled steel sheets with a thickness of 1 mm obtained by performing normal casting, hot rolling, pickling, and cold rolling were used as test materials 1 to 72 (see Table 1). For these test materials, annealing treatment and hot-dip galvanizing treatment are carried out in a continuous hot-dip galvanizing equipment equipped with a full-radiant tube heating furnace. Since the full radiant tube type heating furnace is used, not only is it less likely to cause roll sticking, but the productivity is also good. Corresponding phase transition point A in Table 1 c3 point temperature T Ac3 It calculated using the calculation formula of the transformation temperature provided by the website (http: / / www-it.jwes.or.jp / weld_simulator / cal1.jsp) of the Japan Welding Engineering Society Welding Technology Information Center.

[0217] Table 1

[0218] [Table 1] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com