Flow controller and water treatment system

A technology of flow controller and flow surface, which is applied in the field of flow controller, can solve the problems of continuous supply of raw water and small valve flow channels, etc., and achieve the effects of reasonable area design, material cost saving and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

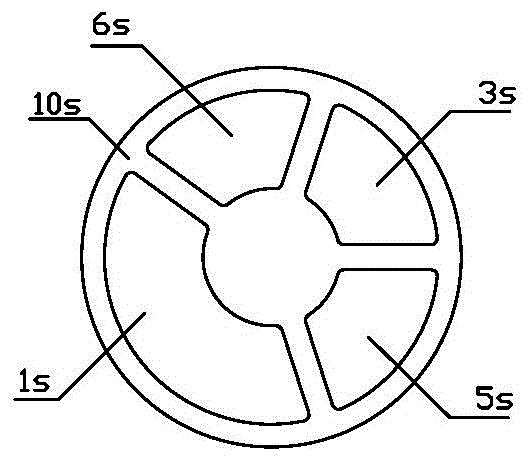

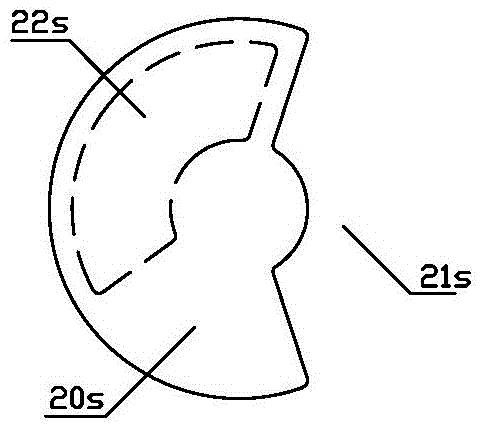

[0278] The scheme of continuous water supply during flushing, single-ring four-hole fixed valve plate, and single water inlet channel.

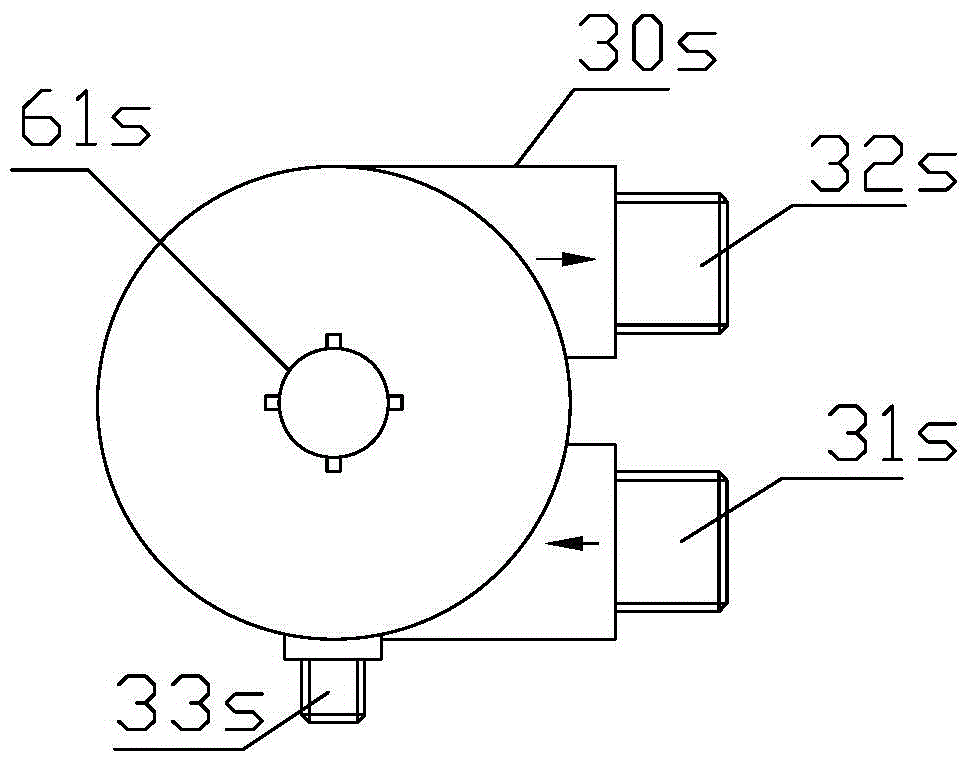

[0279] Such as Figure 1 to Figure 4 As shown, use Figure 2 to Figure 3 The fixed-moving valve combination shown is a multi-functional control valve, including a valve body 30s, a cover 60s, a valve stem 61s, a fixed valve piece 10s and a moving valve piece 20s placed in the valve body 30s and fitted with end face rotation and sealing. , the moving valve plate 20s is connected to the valve stem 61s, the valve body 30s is provided with a raw water inlet 31s, a purified water outlet 32s, a sewage discharge interface 33s, a filter element first interface 38s and a filter element second interface 39s, and the fixed valve plate 10s is provided with: The first interface channel 1s of the filter element, the second interface channel 3s of the filter element, the fifth through hole 5s and the sixth through hole 6s, in the control valve, the first i...

Embodiment 2

[0285] The scheme of no water supply during flushing, single-ring six-hole fixed valve plate, and double water inlet channels.

[0286] Such as figure 1 , Figure 10 to Figure 12 As shown, use Figure 10 to Figure 11 The fixed-moving valve combination shown is a multi-functional control valve, including a valve body 30s, a cover 60s, a valve stem 61s, a fixed valve piece 10s and a moving valve piece 20s placed in the valve body 30s and fitted with end face rotation and sealing. , the moving valve plate 20s is connected to the valve stem 61s, the valve body 30s is provided with a raw water inlet 31s, a purified water outlet 32s, a sewage discharge interface 33s, a filter element first interface 38s and a filter element second interface 39s, and the fixed valve plate 10s is provided with: The first through hole 102s, the second through hole 202s, the third through hole 302s, the fourth through hole 402s, the fifth through hole 502s and the sixth through hole 602s, in the contr...

Embodiment 3

[0292] No water supply during flushing, single-ring four-hole fixed valve plate, and single water inlet channel.

[0293] Such as figure 1 , Figure 18 , Figure 19 and Figure 12 As shown, use Figure 18 to Figure 19 The fixed-moving valve combination shown is a multi-functional control valve, including a valve body 30s, a cover 60s, a valve stem 61s, a fixed valve piece 10s and a moving valve piece 20s placed in the valve body 30s and fitted with end face rotation and sealing. , the moving valve plate 20s is connected to the valve stem 61s, the valve body 30s is provided with a raw water inlet 31s, a purified water outlet 32s, a sewage discharge interface 33s, a filter element first interface 38s and a filter element second interface 39s, and the fixed valve plate 10s is provided with: The first interface channel 103s of the filter element, the second interface channel 303s of the filter element, the fifth through hole 503s and the sixth through hole 603s. The channel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com