Capsule filling, drying and polishing integrated device

A filling device and drying device technology, applied in capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve the problems of high labor intensity, complicated processing steps, low work efficiency, etc., and achieve a high degree of automation, easy disassembly and cleaning, and saving The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

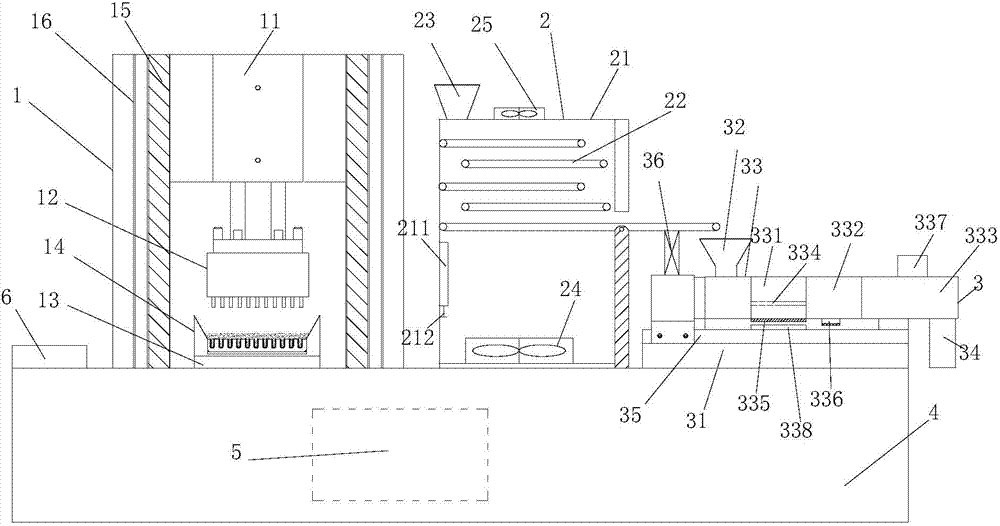

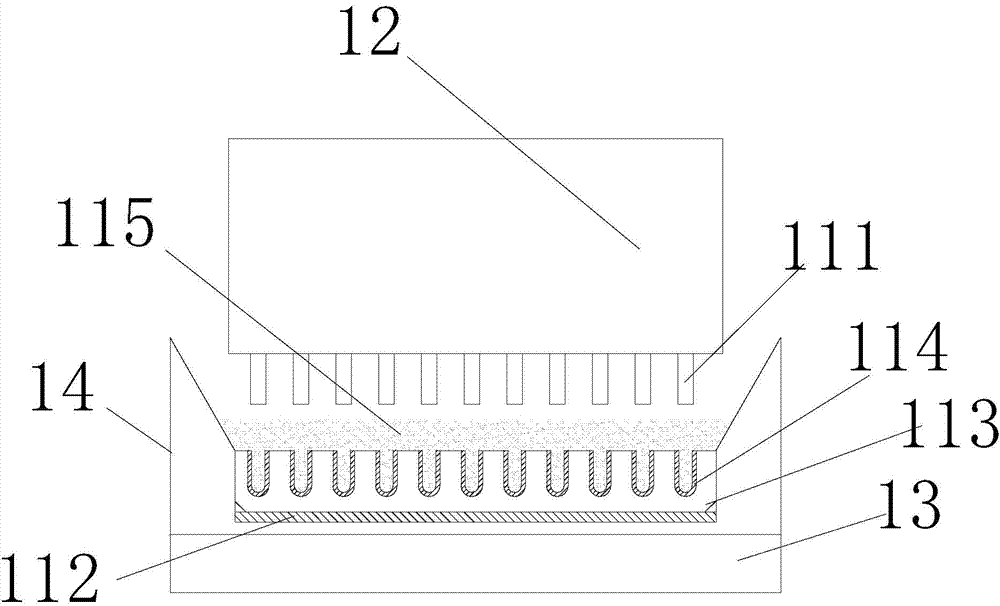

[0017] refer to figure 1 , figure 2 , a capsule filling, drying and polishing integrated device of the present invention, comprising a filling device 1, a drying device 2, a polishing device 3, and a large chassis 4, wherein a drive motor 5 is provided inside the large chassis 4, and the upper end of the large chassis 4 is provided with Console 6, the filling device 1 includes a lifting device 11, a filling pump 12, a first workbench 13, a storage hopper 14 is installed on the first workbench 13, and the lifting device 11 is installed on a lifting fixed rod 15 , the lifting fixing rod 15 is connected with the mounting bracket 16, the lower end of the lifting device 11 is provided with a filling pump 12, the drying device 2 is provided with a first feeding hopper 23, and the first feeding hopper 23 is installed on a small Outside the cabinet 21, a conveyor belt 22 is provided at the outlet of the first feeding hopper 23 lower end, the bottom of the small cabinet 21 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com