High-polishing-degree CMP polishing solution and preparation method thereof

A technology of polishing liquid and cyclodextrin, applied in polishing compositions, chemical instruments and methods, polishing compositions containing abrasives, etc., can solve problems such as poor polishing degree of polishing liquid, and achieve improved polishing degree and improved polishing degree. , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

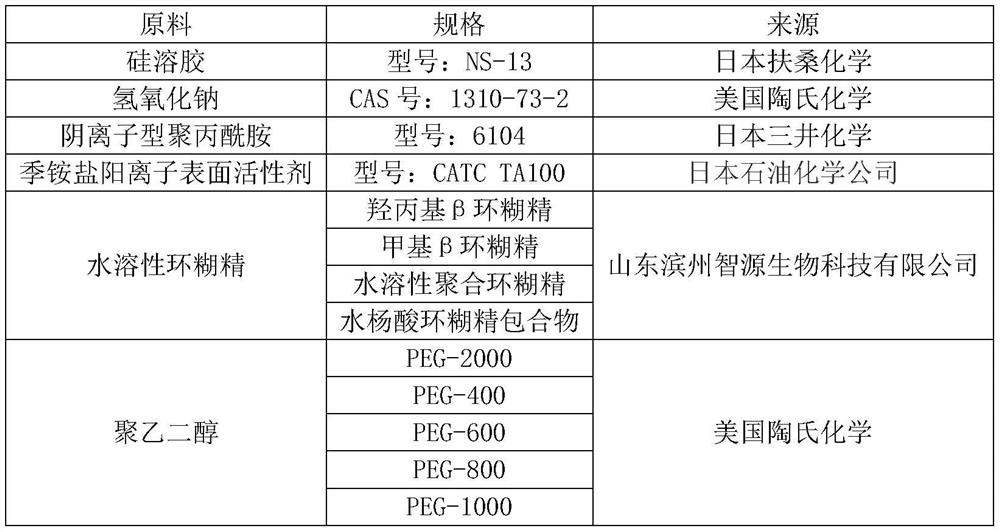

[0036] A high polishing degree CMP polishing liquid, the preparation method is: after mixing 30kg of abrasives and 64.2kg of water, 1.5kg of water-soluble cyclodextrin and 0.1kg of polyethylene glycol are mixed evenly, and then 4kg of pH regulator and 0.2 kg surfactant mixed evenly to prepare a high polishing degree CMP polishing fluid;

[0037] The abrasive material used is silica sol, the pH regulator used is sodium hydroxide, the surfactant used is anionic polyacrylamide, the polyethylene glycol used is PEG-2000, and the water-soluble cyclodextrin used is hydroxypropyl beta cyclodextrin.

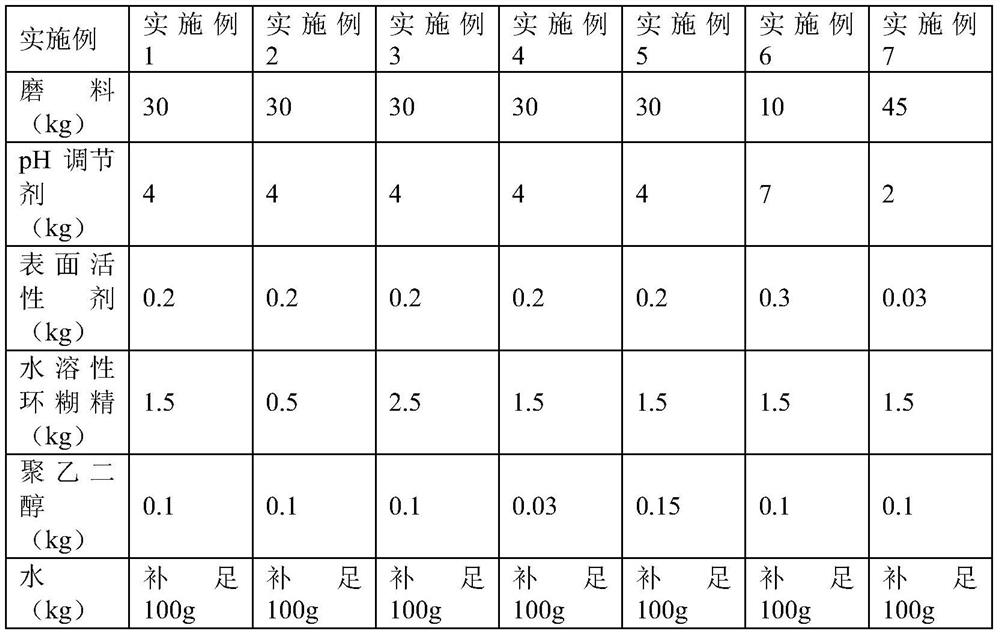

Embodiment 2-7

[0039] Embodiments 2-7 are all based on Embodiment 1, and differ from Embodiment 1 only in that the amount of each raw material is different, see Table 2 for details.

[0040] Table 2. Each raw material source of embodiment 1-7

[0041]

Embodiment 8

[0043] Example 8 is based on Example 1, and the only difference from Example 1 is that the water-soluble cyclodextrin used is a mixture of methyl β-cyclodextrin and water-soluble polymeric cyclodextrin, and methyl β-cyclodextrin and water-soluble The weight ratio of non-polymeric cyclodextrin is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com