Particle manipulation system with out-of-plane channels

A technology for manipulating systems and particles, applied in the field of systems for manipulating small particles, can solve problems such as loss of function, cell damage, unavailability, etc., and achieve the effect of improving sorting speed and accuracy, and fast actuation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

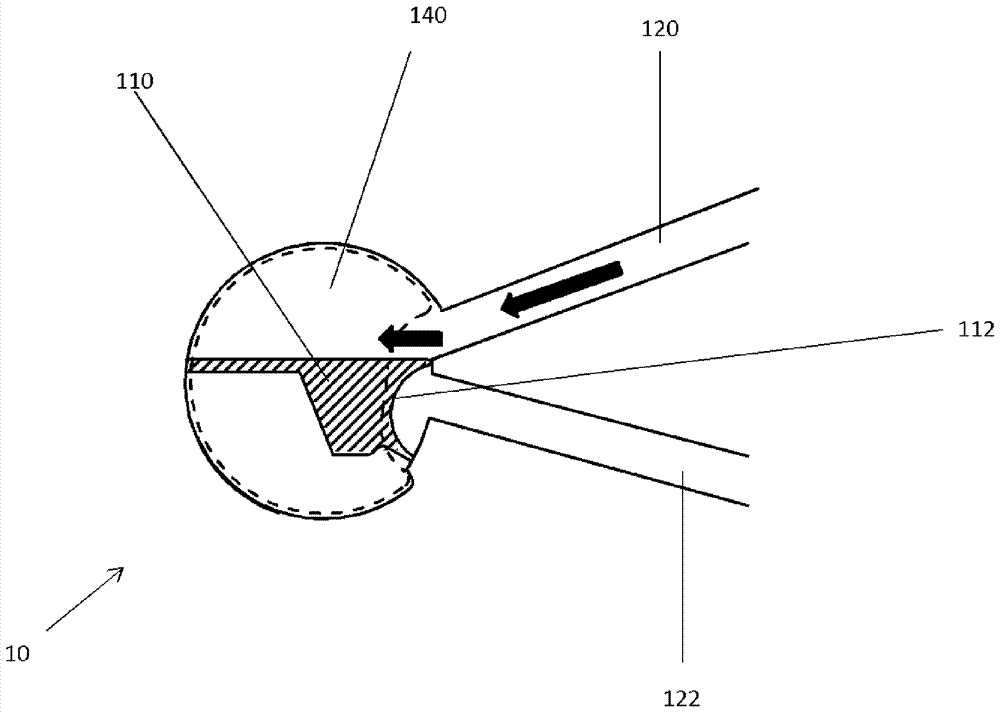

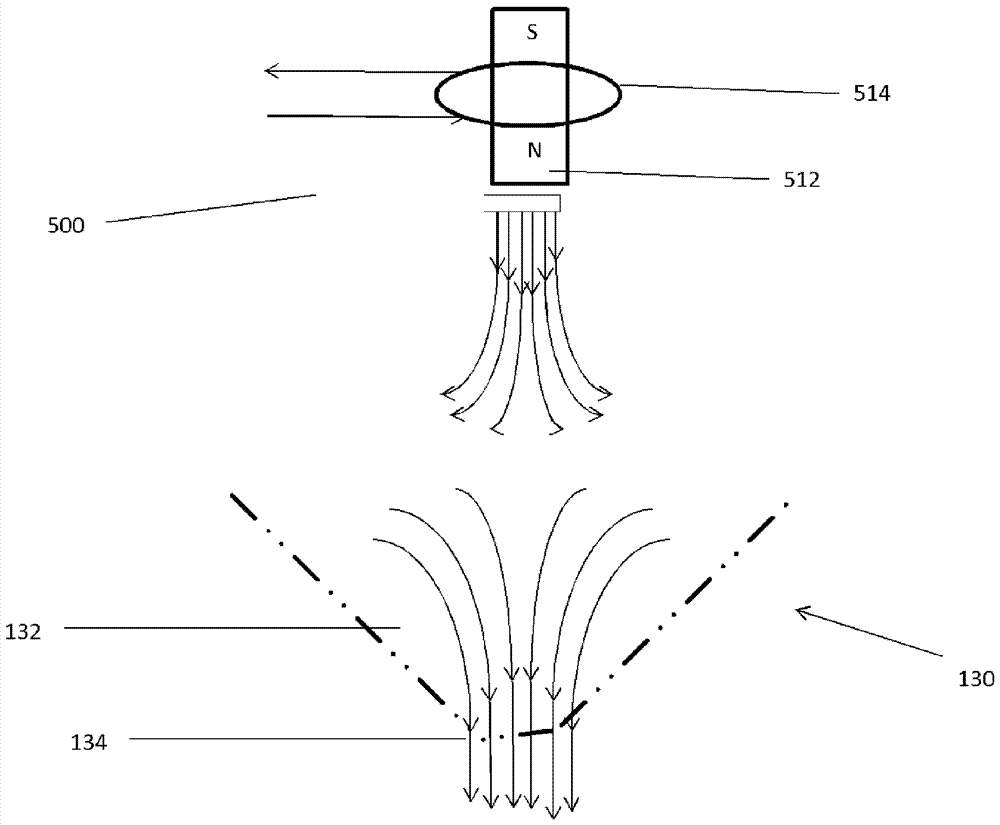

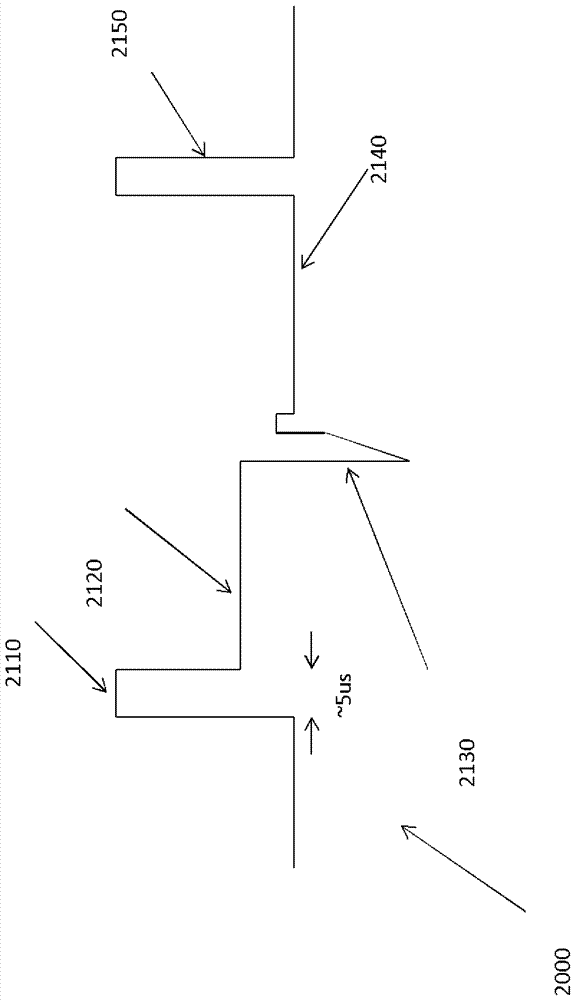

[0028] The system described herein is a particle sorting system that can utilize the microchannel configuration of a MEMS particle manipulation system. More generally, the systems and methods describe a particle manipulation system having an inlet channel and a plurality of output channels, wherein at least one of the plurality of output channels is disposed in a different plane than the inlet channel. This configuration has some significant advantages over the prior art.

[0029] In the figures discussed below, like reference numerals are intended to refer to like structures, and these structures are shown at various levels of detail to provide a clear view of the important features of the novel device. It should be understood that these figures do not necessarily depict structures to scale, and that directional designations such as "top," "bottom," "upper," "lower," "left," and "right" are arbitrary, as the device may be Constructed and operated in any particular orientatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com