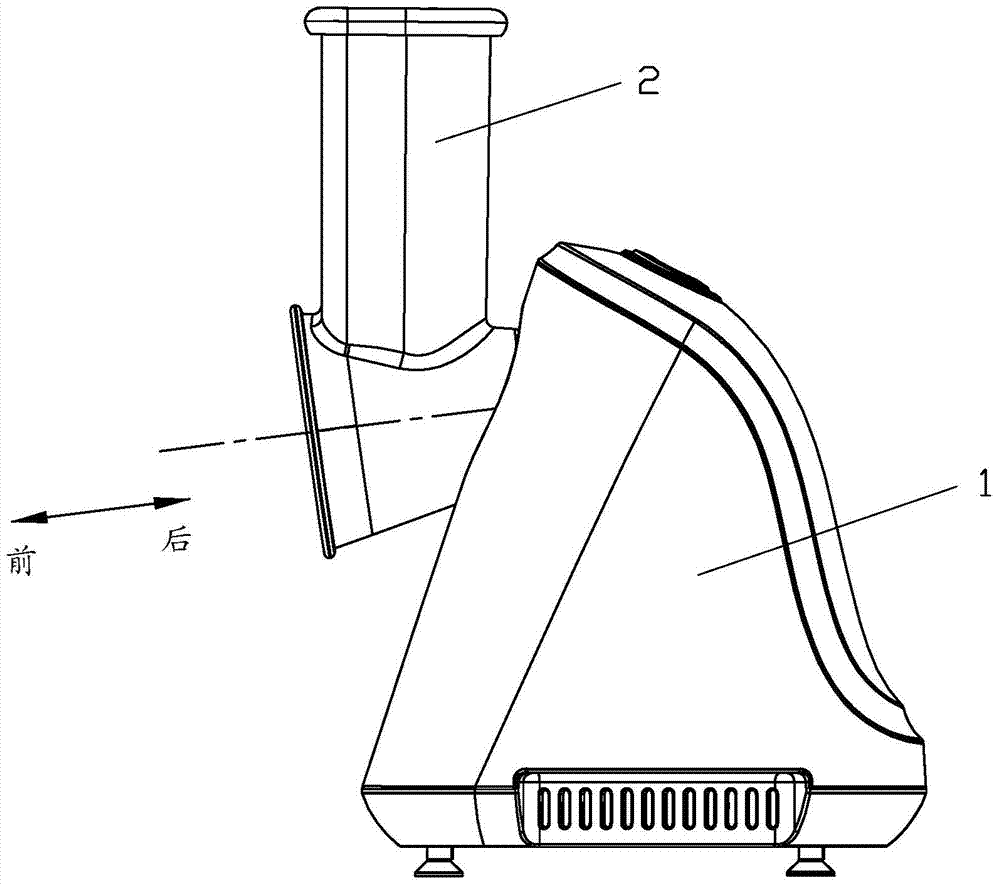

Food cutting machine

A cutting machine and food technology, which is applied in the direction of grain processing, etc., can solve the problems of complex structure, large noise, and large number of parts, and achieve the effect of simple, reasonable and compact structure, reduced wear and noise, and smooth rotation of the winch drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

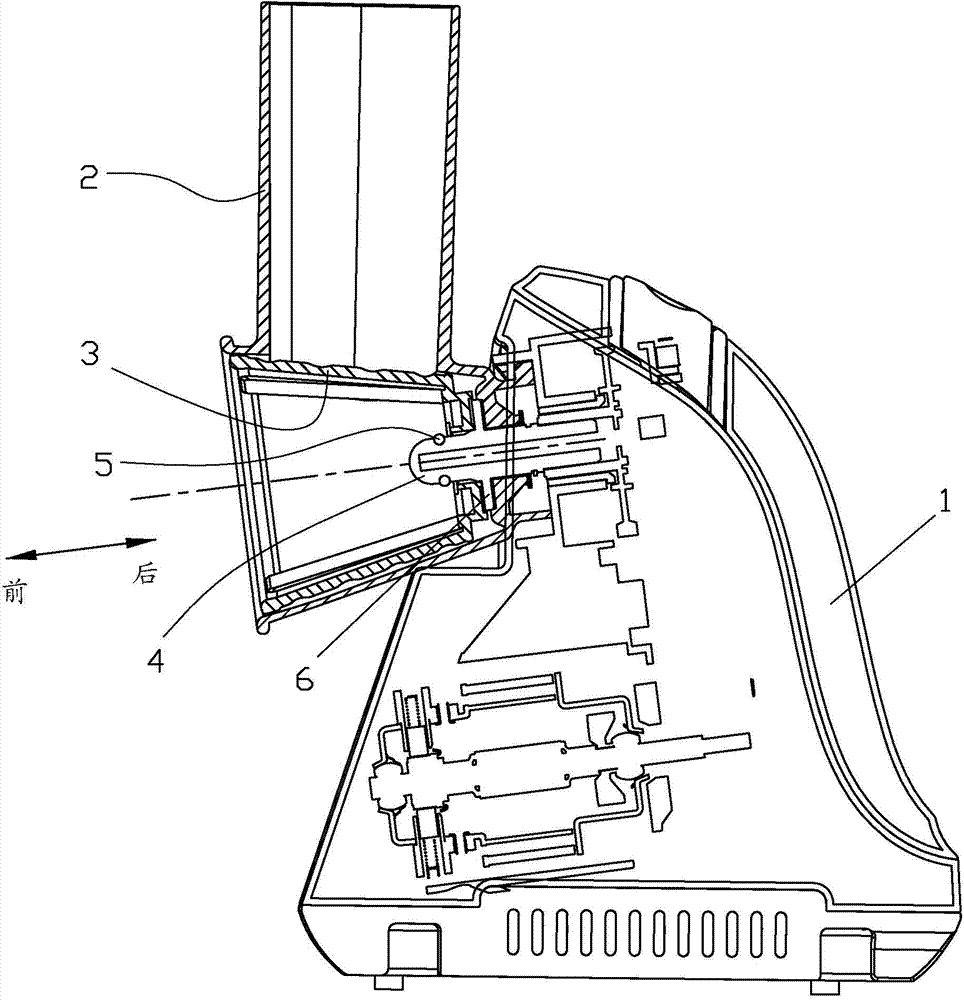

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The front and rear in the following, unless otherwise specified, generally refer to the direction of the axis of the power drive rod 4, with the side where the food outlet of the twist drum 3 is located as the front, as shown by the arrow in the accompanying drawings.

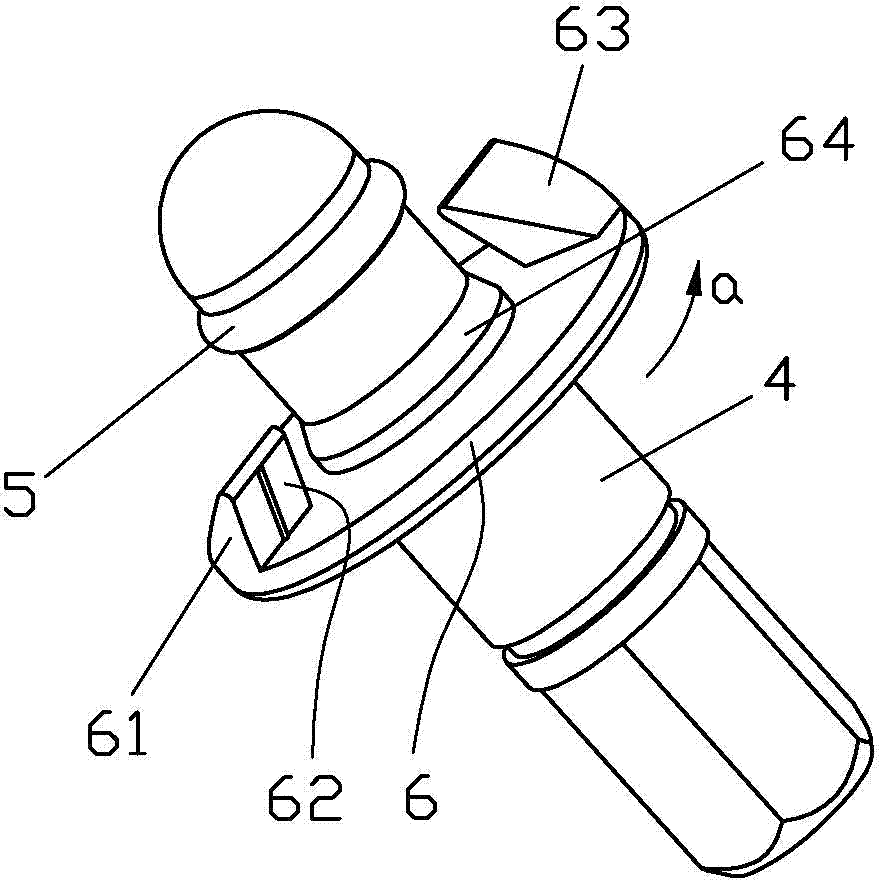

[0016] refer to Figure 1~Figure 5 , a kind of food cutting machine of the present invention, comprises fuselage 1, and described fuselage 1 is provided with feeding cylinder 2, and in feeding cylinder 2, is installed with twisted cylinder 3, and described twisted cylinder 3 is connected on the power drive bar 4, the twisted cylinder 3 is set on the power drive rod 4, and the front end of the power driven rod 4 passes through the sleeve hole 34 on the rear end surface of the twisted cylinder 3, and then is set with glue to prevent the twisted cylinder 3 from sliding forward. Rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com