Express sorting method and system based on robot visual servo technology

A technology of robot vision and robot, which is applied in sorting and other directions, to achieve the effect of good sorting quality, low item damage rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

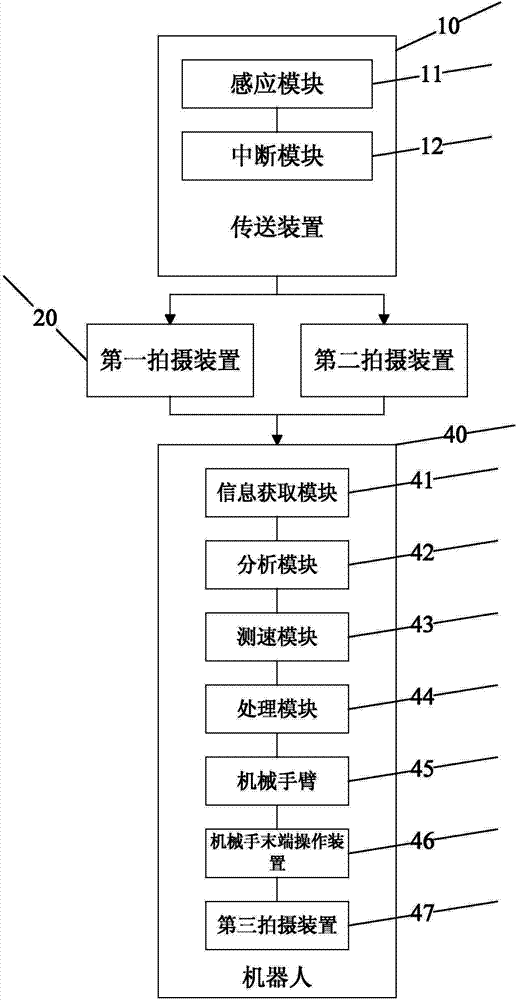

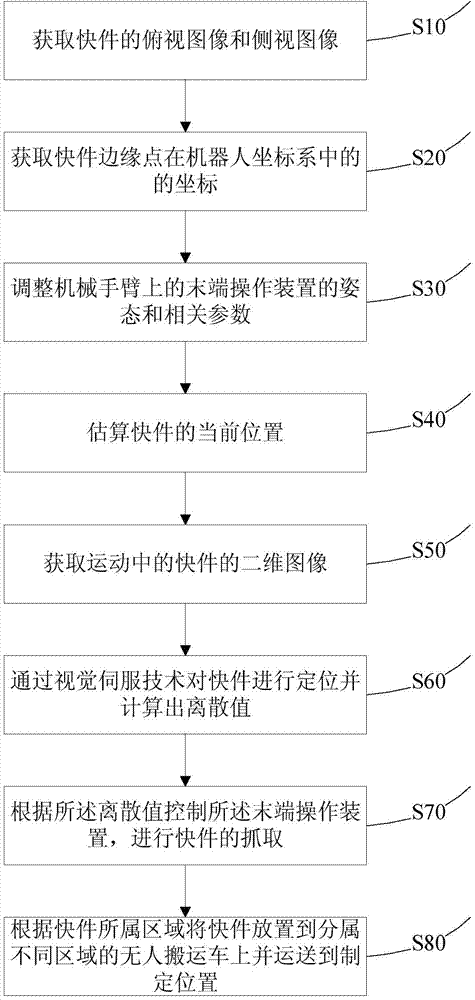

[0043] The express parcels that need to be sorted are divided into box-type express parcels and bag-type express parcels. Before sorting, the two types of parcel express parcels are separated and sent by two conveyors respectively. In this example, packaging box-type express mail is taken as an example, please refer to figure 1 In this embodiment, an express sorting system based on robot visual servoing technology includes a conveyor device 10, a first camera device 20, a second camera device 30, and a robot 40. The conveyor device 10 is provided with a A photographing area and a sorting area, the first photographing device 20 is located directly above the photographing area, the second photographing device 30 is located to the side of the photographing area, and the robot 40 is located on the conveying device 10 The end of the transmission device 10, the first camera 20, the second camera 30, the robot 40 can be connected via a network or a local area network. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com