Floor machining center ram

A machining center, floor-standing technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of limited range of bearing capacity, difficult to achieve precision machining, low machining accuracy, etc., to ensure long-term stable work. , The effect of enhancing force performance and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

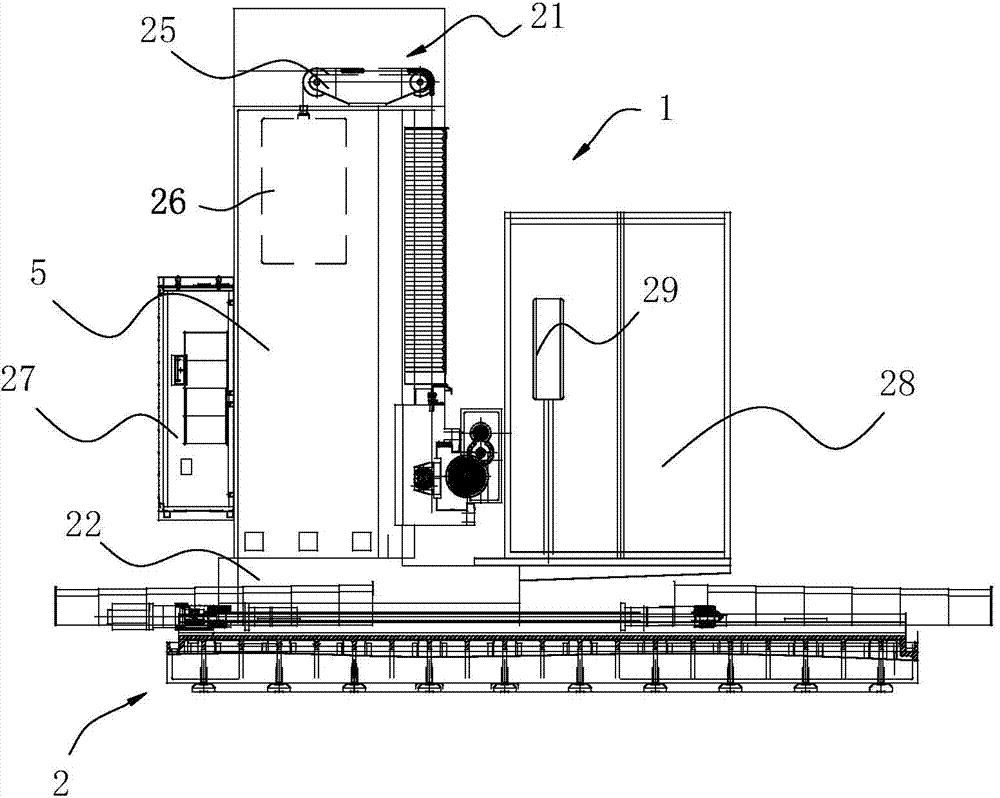

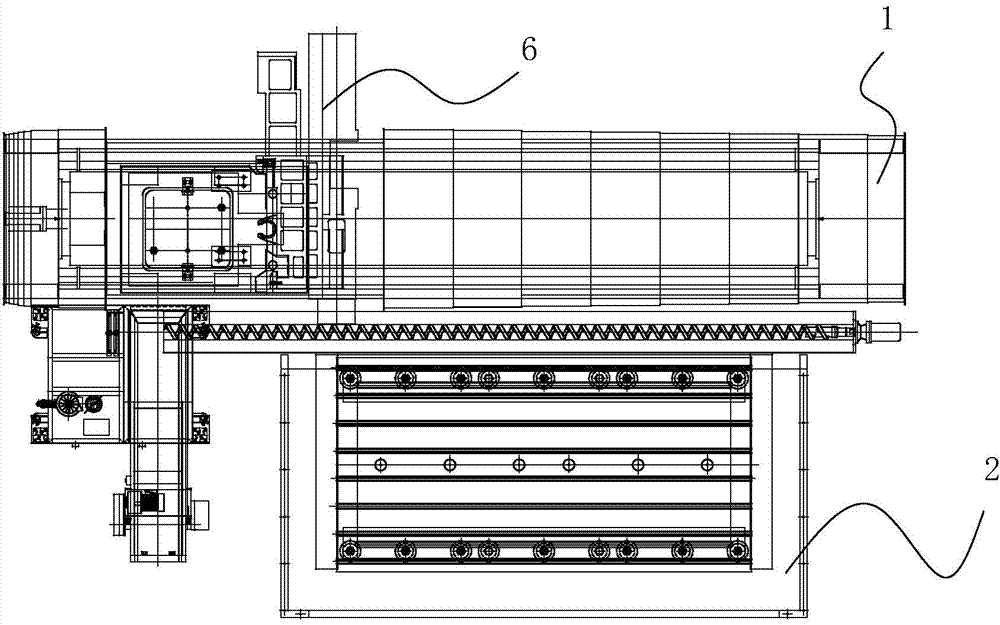

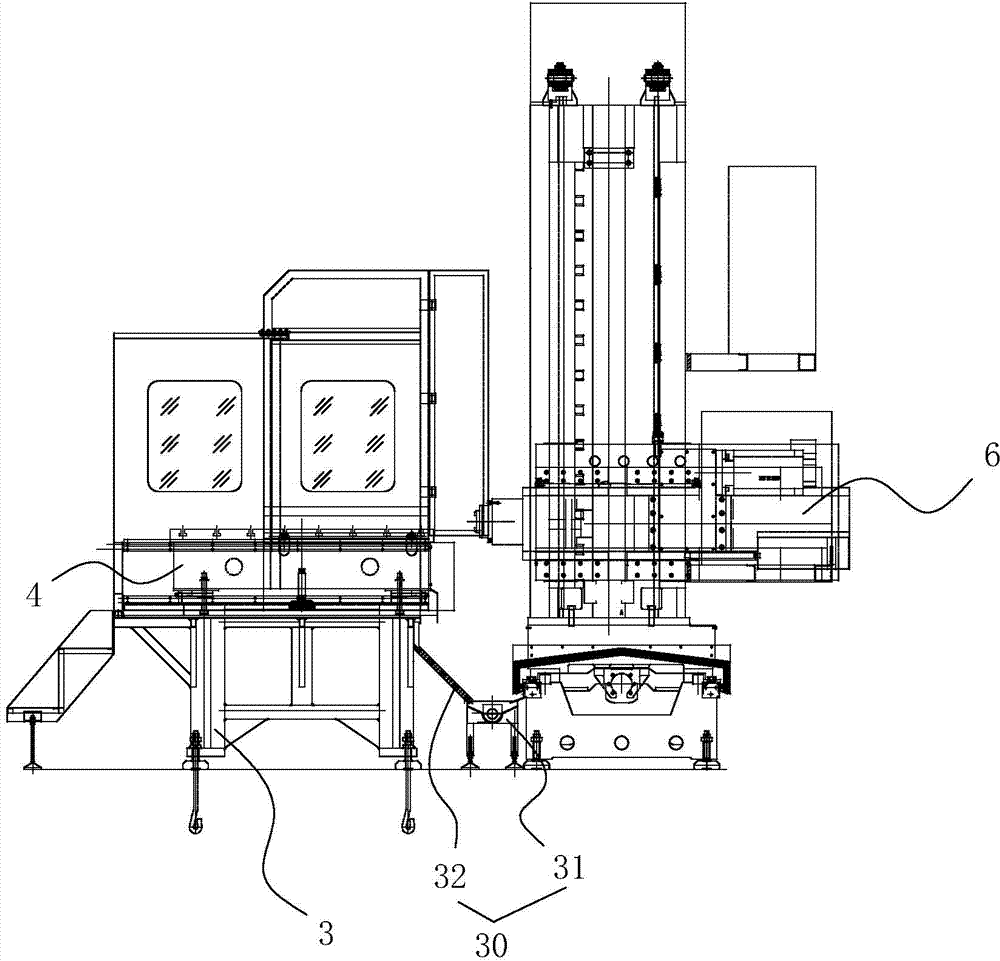

[0027] like Figure 1-6 As shown, in this embodiment, a floor-standing horizontal machining center of the present invention includes a tool installation platform 1 and a workpiece installation platform 2 arranged side by side and installed on the ground respectively. The workpiece installation platform 2 includes a fixing seat 3 and a set On the workbench 4 on the fixed seat 3, the tool installation platform 1 is provided with a first moving track along the horizontal direction, and a column 5 is vertically arranged on the first moving track, and the column 5 can slide along the first moving track. There is a second moving track perpendicular to the first moving track, the second moving track is provided with a ram 6 for installing the main shaft 7, the main shaft 7 is installed in the ram 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com