Machining method of thin-wall curved surface type part

A processing method and parts technology, which is applied in the field of aircraft numerical control processing, can solve the problems of poor processing quality, deformation, and scrapping of parts, and achieve the effects of full and fast parts, overcoming out-of-tolerance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

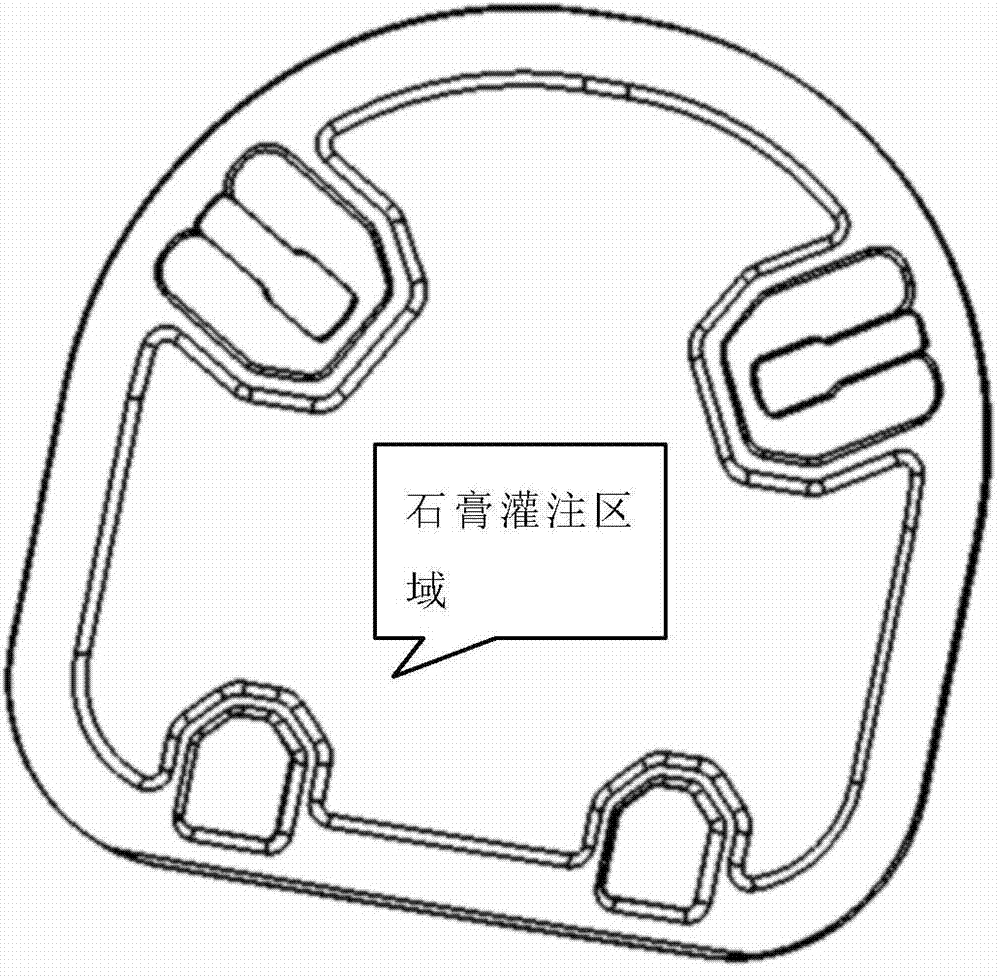

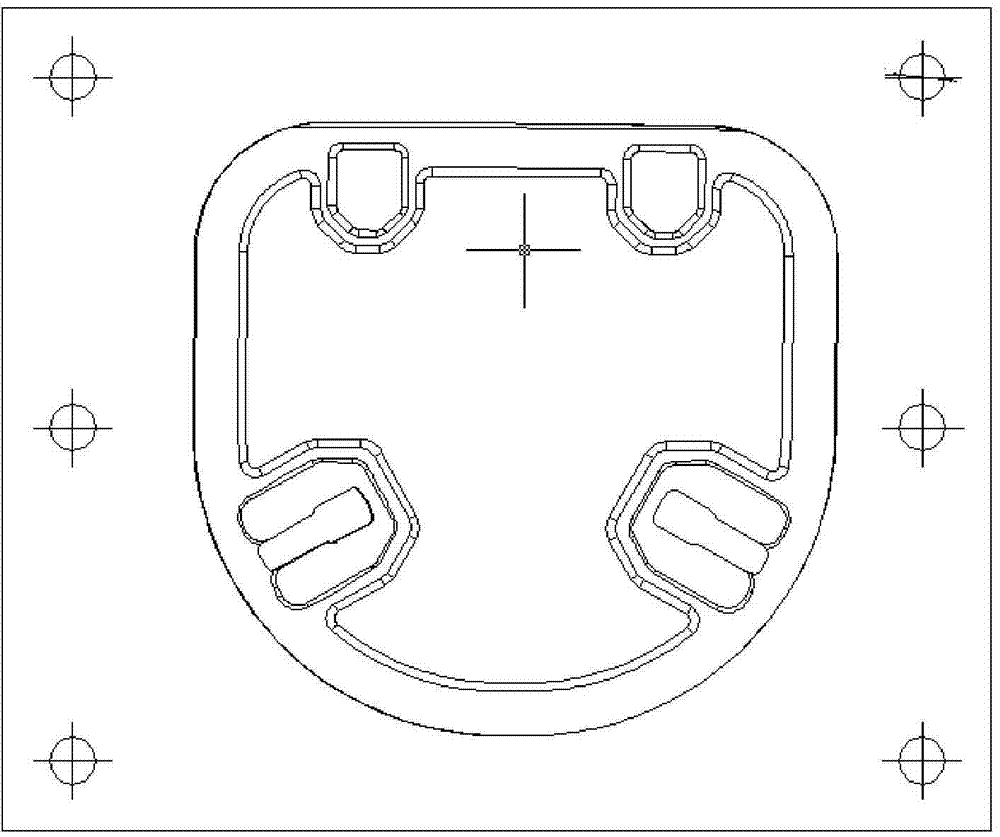

[0018] follow the next figure 2 Clamp the part blank in the same way, after the first surface is completely finished, on the processed surface (see figure 1 ) to cover the effective area of the part (exposed area on the surface of the part, except the blank surface) as much as possible to prevent corrosion after pouring plaster. Then pour gypsum into it, and after the gypsum is completely hardened, perform super-flat treatment on the side where the gypsum is laid (injecting gypsum makes the processed curved surface no longer suspended, completely eliminating the out-of-tolerance of parts caused by vibration). After super-flatness is required, the plaster surface is consistent with the rough surface. Then turn the part upside down and fasten it on the fixture, and tighten it with bolts. Roughing and finishing are performed on the other side. This kind of operation can completely avoid the out-of-tolerance caused by the vibration of the part due to hollowness after one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com