Low odor weather resistant PA (polyamide)/ABS (acrylonitrile-butadiene-styrene) composite material

A composite material and low-odor technology, which is applied in the field of composite materials and low-odor weather-resistant PA/ABS composite materials, can solve problems that affect product market reputation, unpleasant smell, and strong odor, and achieve good social and economic benefits. Weather resistance, odor improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

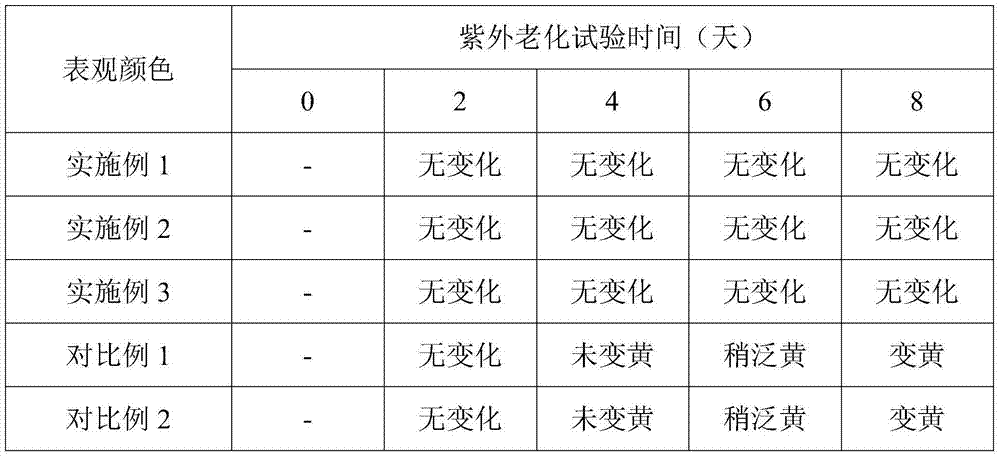

Examples

Embodiment 1

[0016] 30 parts of PA, 35 parts of ABS, 5 parts of compatibilizer, 5 parts of reactive castor oil, 3 parts of composite antioxidant, 1 part of initiator, 2 parts of heat stabilizer and 3 parts of activated carbon-nano-titanium dioxide compound Mix evenly in a mixer, then extrude through a parallel twin-screw extruder, cool and granulate to obtain a PA / ABS composite material.

Embodiment 2

[0018] 40 parts of PA, 50 parts of ABS, 8 parts of compatibilizer, 7 parts of reactive castor oil, 5 parts of composite antioxidant, 2 parts of initiator, 4 parts of heat stabilizer, 5 parts of activated carbon-nano-titanium dioxide composite and coloring Mix 3 parts of the agent evenly in a high-speed mixer, then extrude through a parallel twin-screw extruder, cool and granulate to obtain a PA / ABS composite material.

Embodiment 3

[0020] 50 parts of PA, 60 parts of ABS, 15 parts of compatibilizer, 8 parts of reactive castor oil, 6 parts of composite antioxidant, 2 parts of initiator, 5 parts of heat stabilizer and 6 parts of activated carbon-nano-titanium dioxide composite were processed at high speed Mix evenly in a mixer, then extrude through a parallel twin-screw extruder, cool and granulate to obtain a PA / ABS composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com