Polycrystalline diamond compact bit manufacturing

A technology of polycrystalline diamond and composite sheet, applied in the direction of drill bits, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of reducing the quality of PDC cutting teeth, damage of PDC cutting teeth, and improper formation of bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

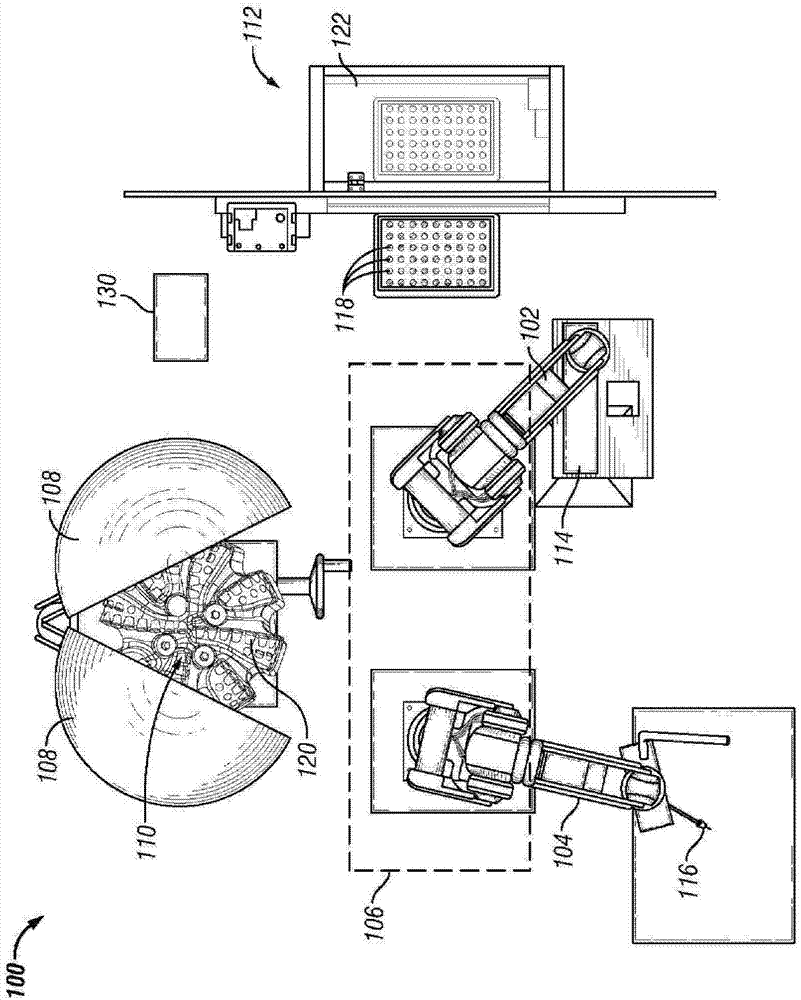

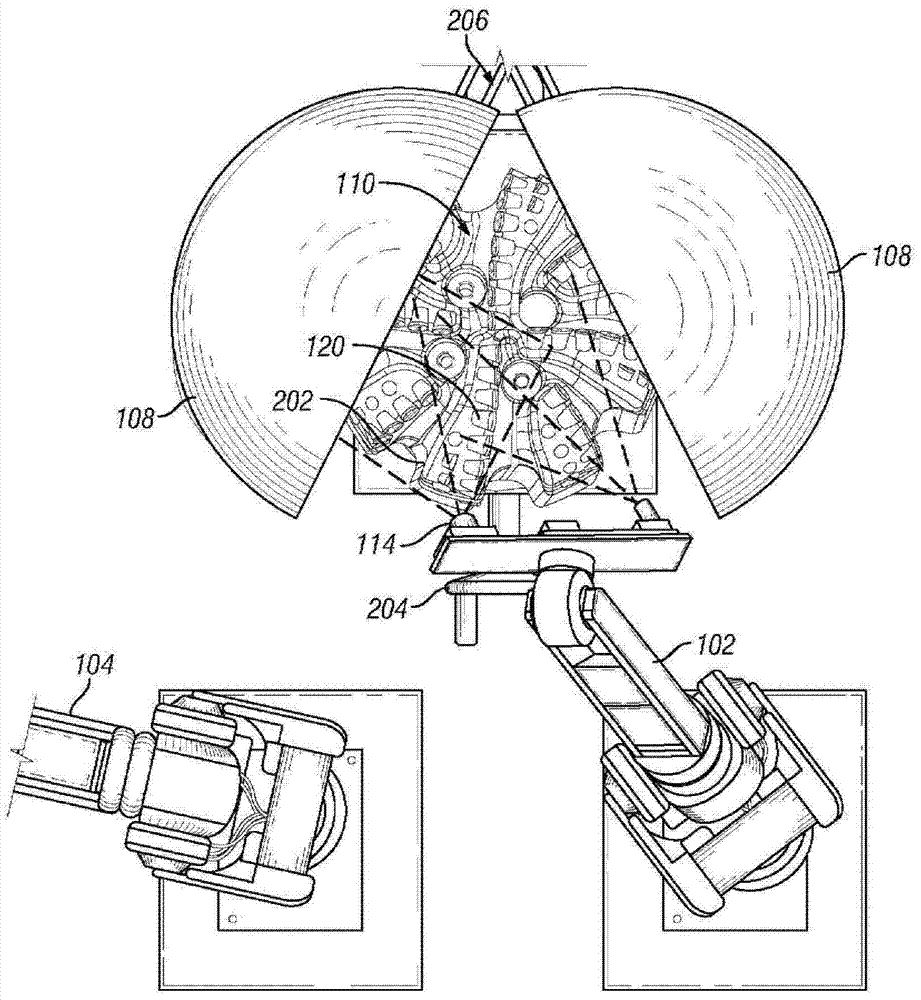

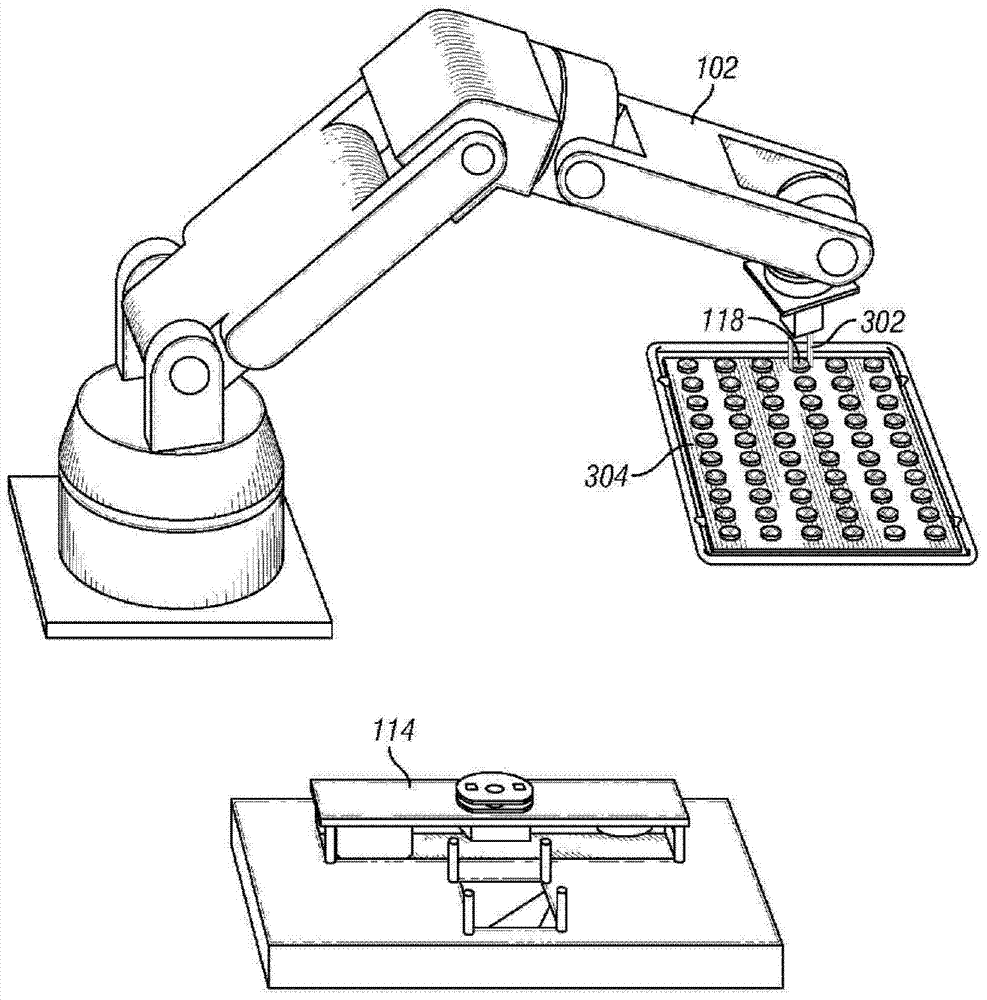

[0017] The present disclosure generally relates to downhole tools for subterranean drilling. In particular, this disclosure relates to the manufacture of drill bits having cutters (eg, PDC cutters) that can be adversely affected by overheating during drill manufacturing. While the description of the exemplary embodiments is in terms of PDC bits and PDC cutters, embodiments including bits that are not PDC bits are also contemplated within the scope of this description.

[0018] The present invention may be better understood by reading the following non-limiting, exemplary embodiment description with reference to the accompanying drawings, in which like parts are identified by like reference numerals in each drawing. According to an exemplary embodiment, a method of manufacturing a PDC bit includes inspecting a plurality of cutting teeth to determine a size for each of the plurality of cutting teeth. The method also includes inspecting the plurality of pockets of the drill body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com