Air (exhausted smoke and gas) cooling and condensing purification system

A technology for purifying systems and air, applied in exhaust devices, mufflers, engine components, etc., can solve problems such as low effect, air pollution, and failure to solve the atmosphere, and achieves a very good use effect, low cost, and simple installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

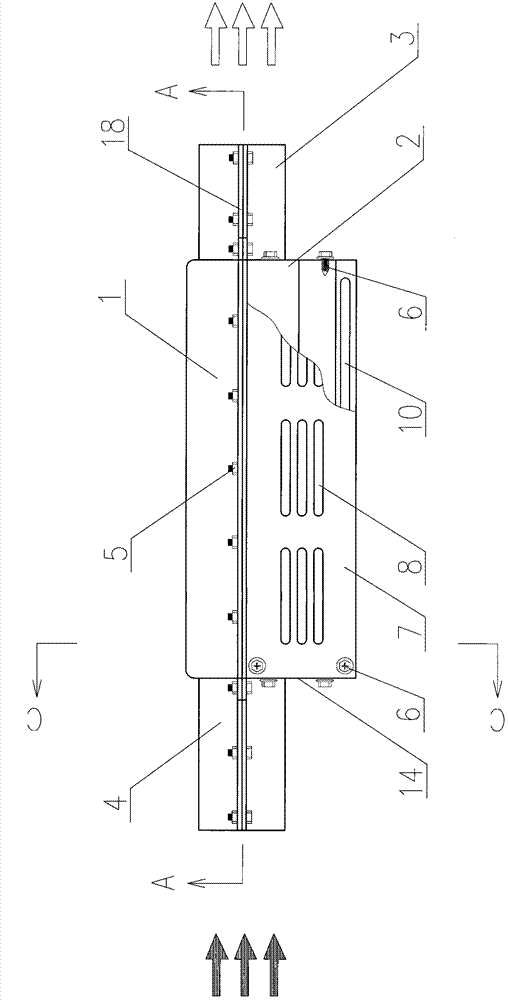

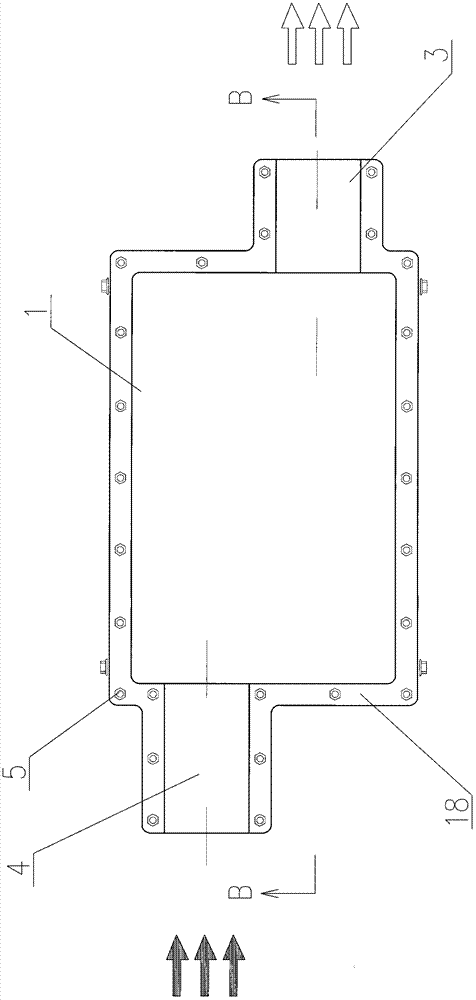

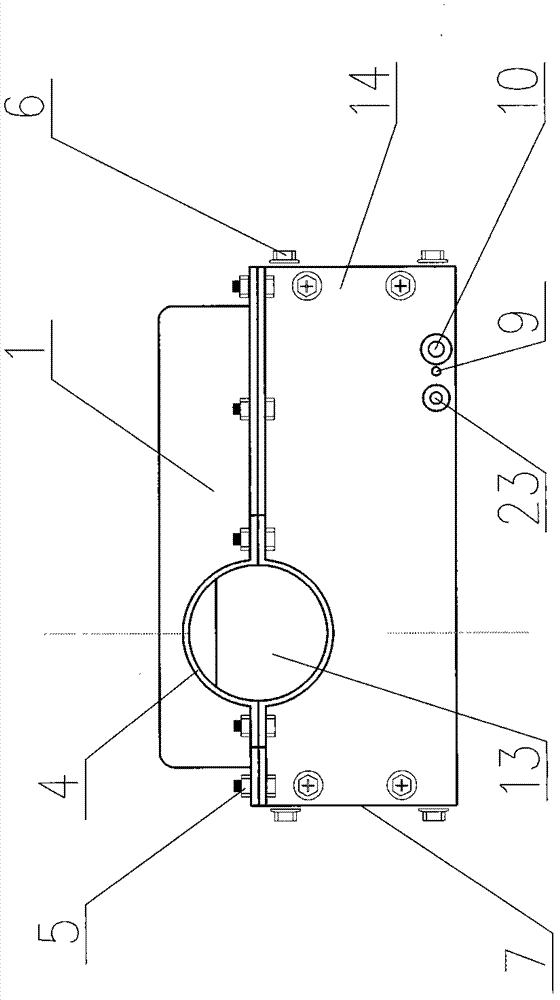

[0023] exist Figure 1-10 It is shown in the figure that the automobile exhaust cooling and condensation purifier is mainly composed of the purifier shell top cover plate (1), the purifier shell bottom cover plate (2), the purifier air outlet (3), the purifier air inlet (4 ), fastening bolts (5), self-tapping screws (6), outer baffles (7), diffuser holes (8), temperature sensor signal wires (9), refrigeration system return pipes (10), refrigeration system liquid supply pipes (11), dry filter (12), reverse flow partition (13), housing baffle (14), filter cotton bracket (15), fine filter cotton (16), coarse filter cotton (17), housing Connecting flange (18), fixed card (19), floor drain hole (20), temperature sensor (21), bottom support plate (22), refrigeration system exhaust pipe (23).

[0024] exist Figure 1-10 As shown in , the top cover plate (1) of the purifier shell and the bottom cover plate (2) of the purifier shell are connected by fastening bolts (5) through the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com