Special stem for LED (Light Emitting Diode) filament lamp

A technology of LED filament lamps and stems, applied in the field of lighting, can solve the problems of complex manufacturing process, short service life and high production cost, and achieve the effects of long service life, low cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

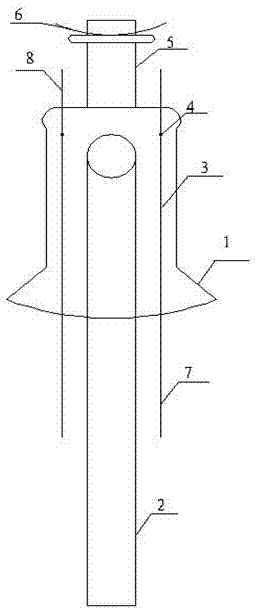

[0011] like figure 1 As shown, a dedicated stem for LED filament lamps, including an inverted trumpet tube 1 and an exhaust rod 2, the exhaust rod 2 is vertical in the horn tube 1, and the two sides of the exhaust rod 2 are provided with wires 3 parallel to each other. A wire node 4 is arranged on the top, and a solid mandrel 5 is placed on the top of the trumpet tube 1, and the upper end of the solid mandrel 5 is bonded with a short nickel wire 6.

[0012] Put the trumpet tube 1, exhaust rod 2, guide wire 3, and solid mandrel 5 into the corresponding equipment of the core column machine, and make it unbonded by preheating, heating, flattening, blowing, drilling, and annealing. The stem of wire, then the solid mandrel 5 is heated and bonded with short nickel wire 6 to make a special stem for LED filament lamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com