Light-driving floating and diving motion device based on bubbles

A motion device and optical drive technology, applied in transportation and packaging, motor vehicles, machines/engines, etc., can solve the problems of limited practical application, difficult motion control, unsustainable, etc., and achieve the goal of improving light-to-heat conversion efficiency and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

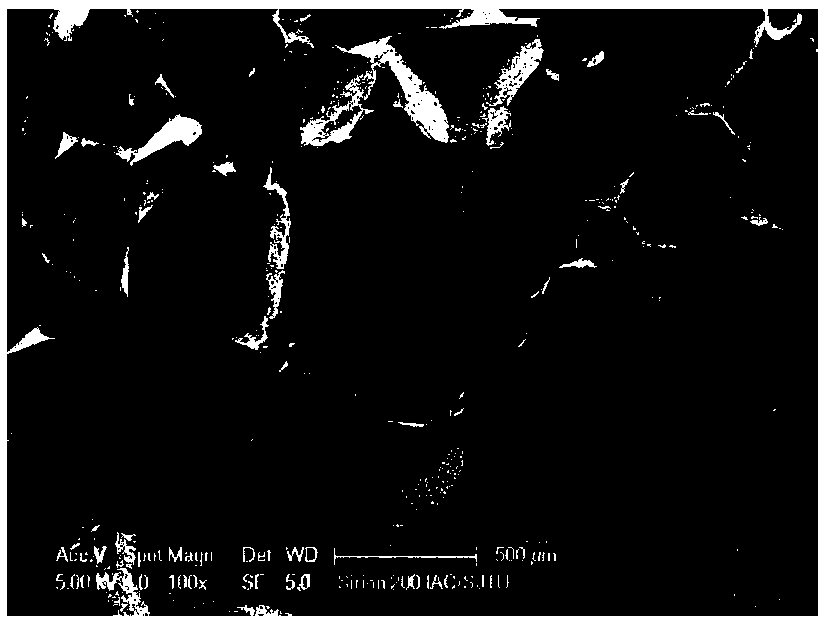

[0039] (1) Mix sodium chloride particles, carbon black particles and liquid PDMS (the three can be mixed according to actual needs, and the general mass ratio is 606:1:100), then pour them into the mold and put it in the oven to make it solidification. Then it is soaked in water, and through continuous extrusion, the sodium chloride particles inside the PDMS are continuously dissolved in the water, leaving small holes of the same size in the corresponding parts. After the sodium chloride particles are completely dissolved, they are dried in an oven to obtain porous PDMS. For its surface structure, see figure 2 As shown, it can be seen that the surface has numerous micro-nano-sized holes.

[0040] (2) Cut the porous PDMS to a suitable size. Through measurement and calculation, iron blocks are used as the weight to make the density slightly greater than that of water, to the extent that it can just dive into the water.

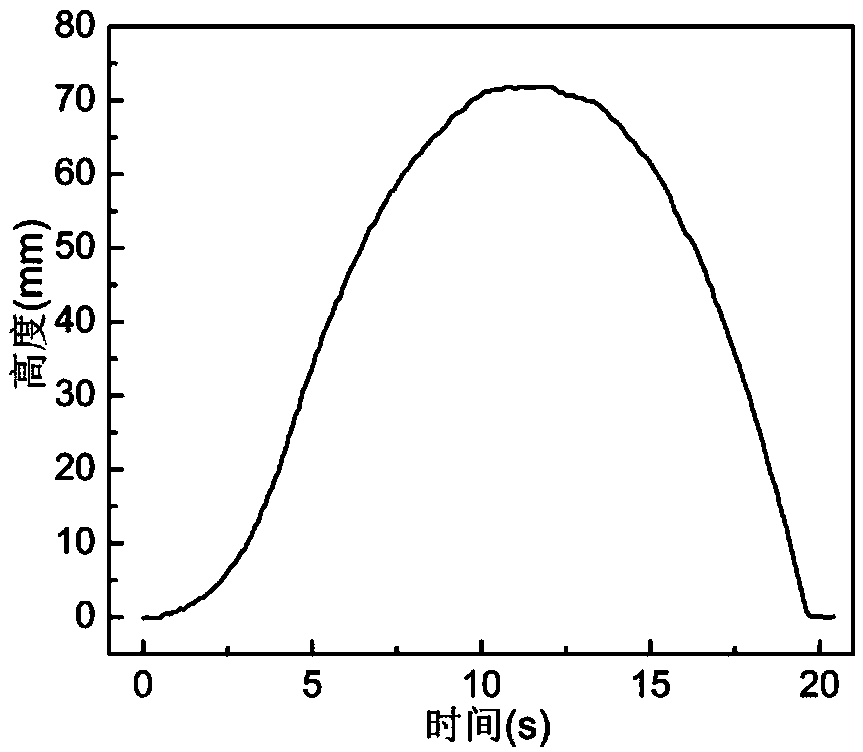

[0041] (3) Put the porous PDMS with iron as a load in the wa...

Embodiment 2

[0044] In this embodiment, the material with electromagnetic wave absorption properties is nano-gold particles; using the method in the embodiment, sodium chloride particles and PDMS are used to make porous PDMS. Then immerse it in 0.5% (m / v) chloroauric acid ethanol solution or drip 0.5% (m / v) chloroauric acid ethanol solution on the porous PDMS, because the residual curing agent in PDMS will cause chlorine Gold acid is reduced, so gold nanoparticles can be synthesized inside the porous PDMS after standing at room temperature for a period of time. Use 532nm laser as the light source driver movement. The rest is the same as in Example 1.

Embodiment 3

[0046] Use metal foam directly as the base material. Put the copper foam at 0.065M K 2 S 2 O 8 In a mixed solution of 2.5M KOH and heated at 60°C for 30 minutes, a chemical reaction occurs on the surface to form a certain microstructure. Then graphene is bonded to the surface of the copper foam through organic matter as an electromagnetic wave absorbing material. Then immerse the whole body in 1.0% (wt%) 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane (PFTS) ethanol solution, react at room temperature for 30 minutes, then take out the solution and put it at 80℃ After heating for 30 minutes, the surface of the copper foam exhibits hydrophobicity through the above chemical modification. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com