Warm-mixed styrene butadiene rubber modified bituminous mixture applicable to cold areas and preparation method thereof

A technology of modified asphalt and styrene-butadiene rubber, which is applied in the field of warm-mix styrene-butadiene rubber modified asphalt mixture and its preparation, can solve the problems of poor storage stability and cumbersome preparation methods, reduce smoke, simplify preparation methods, and solve The effect of technical barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The base asphalt used in this example is Liaohe No. 90 asphalt, and its technical index measurement results are shown in Table 1. The styrene-butadiene latex is PC-1725G, a product of Shanghai Longfu Industrial Co., Ltd., and its physical properties are shown in Table 2. The warm mixing agent is selected from the products of Medwishvik For DAT-H5, see Table 3 for its technical specifications.

[0020] The aggregate is Anshan limestone with AC-13I type gradation. The dosage of base asphalt is 4.6% of aggregate and base asphalt mass. The target grading is shown in Table 4.

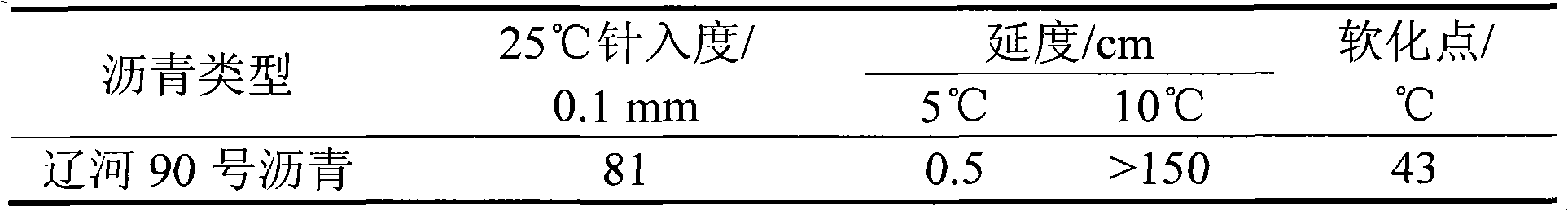

[0021] Table 1 Liaohe asphalt performance test results

[0022]

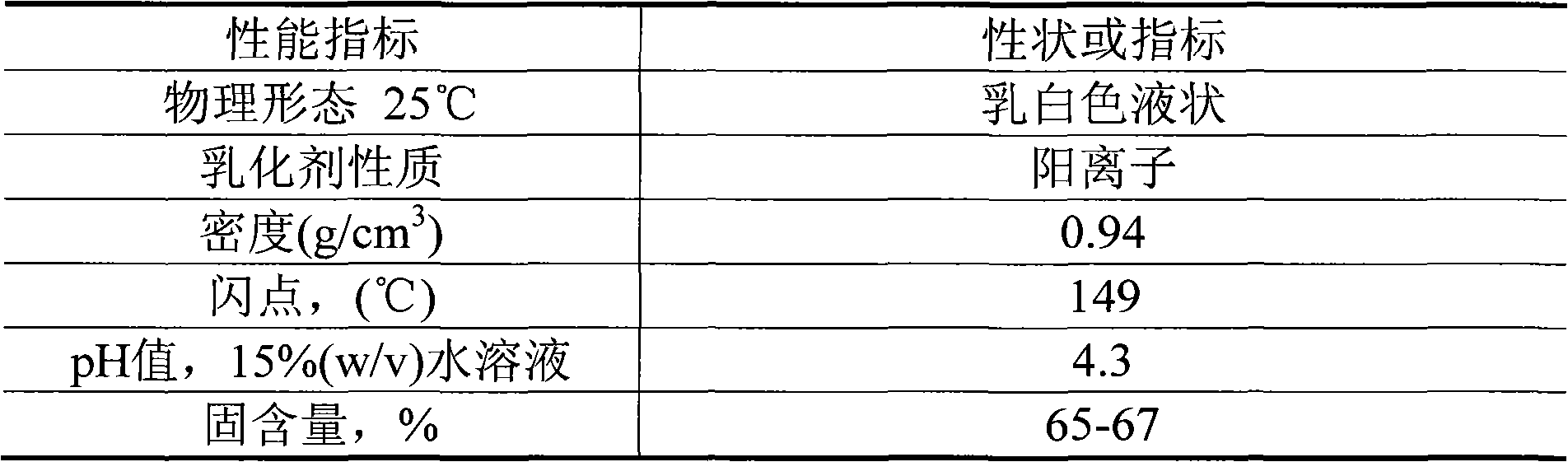

[0023] Table 2 PC-1725G physical properties

[0024]

[0025] Table 3 DAT-H5 technical indicators

[0026]

[0027] Table 4 Target Grading

[0028]

[0029] 1. Evaluate the performance of the mixture in the laboratory. The indoor mixing process is as follows: heat the base asphalt to 150°C, heat the aggregate to 130°...

Embodiment 2

[0038] The aggregates used in this example, the warm mix agent and the gradation of the prepared asphalt mixture are all the same as those in Example 1. Shell No. 90 asphalt is selected as the base asphalt, and its technical index measurement results are shown in Table 6. The amount of the base asphalt is 4.6% of the mass of aggregate and base asphalt. The styrene-butadiene latex is selected from PC-1745, a product of Shanghai Longfu Industrial Co., Ltd., and its physical properties are shown in Table 7.

[0039] Table 6 Shell asphalt performance test results

[0040]

[0041] Table 7 PC-1745 Physical Properties

[0042] Performance

traits or indicators

Physical form 25℃

Milky white liquid

Emulsifier Properties

anion

Density (g / cm 3 )

0.94

Flash point, (°C)

149

pH value, 15% (w / v) in water

10.4

Solid content, %

70-72

[0043] 1. Evaluate the performance of the mixture in the labora...

Embodiment 3

[0052] The gradation of base asphalt, aggregates, warm mix agent and prepared asphalt mixture used in this example is the same as that in Example 1. The consumption of base bitumen is also with embodiment 1. The styrene-butadiene latex is selected from PC-1715, a product of Shanghai Longfu Industrial Co., Ltd., and its physical properties are shown in Table 9.

[0053] Table 9PC-1715 Physical Properties

[0054]

[0055] 1. Evaluate the performance of the mixture in the laboratory. The indoor mixing process is as follows: heat the base asphalt to 150°C, heat the aggregate to 130°C, mix the two at 140°C for 60 seconds, add 5% (relative to the base asphalt mass percentage) of styrene-butadiene latex PC-1715 at 140°C for 60 seconds, then add 5% (relative to the mass percentage of base asphalt) of warm mix agent DAT-H5 and mix at 140°C for 60 seconds, and finally add 6% Mineral powder (Anshan limestone with a particle size of 0.075mm or less, the percentage relative to the ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com