A kind of exposure system and method of multi-dmd splicing

An exposure system and interface technology, which is applied in the field of large-size, large-area DMD exposure systems, can solve problems affecting exposure accuracy, etc., and achieve the effect of overcoming low exposure efficiency, high efficiency, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

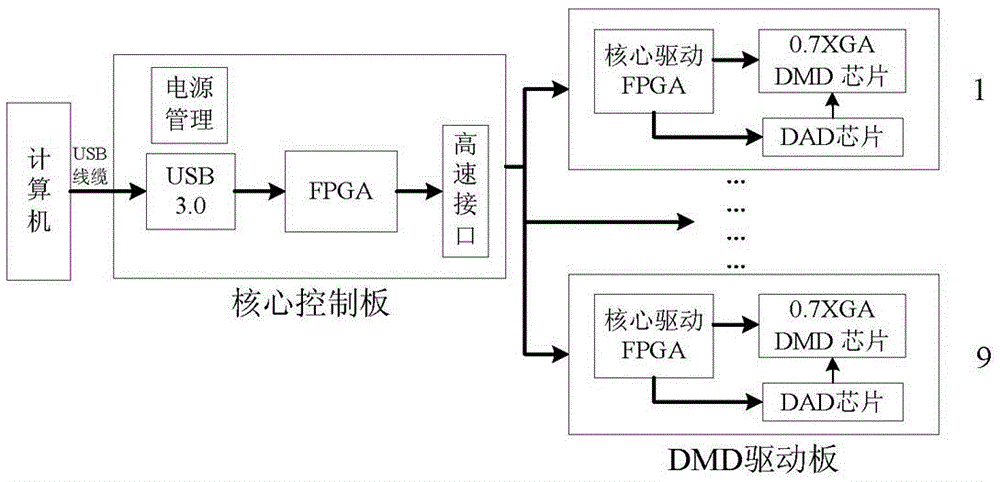

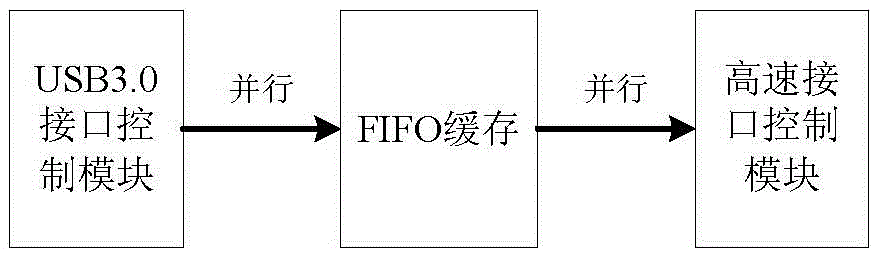

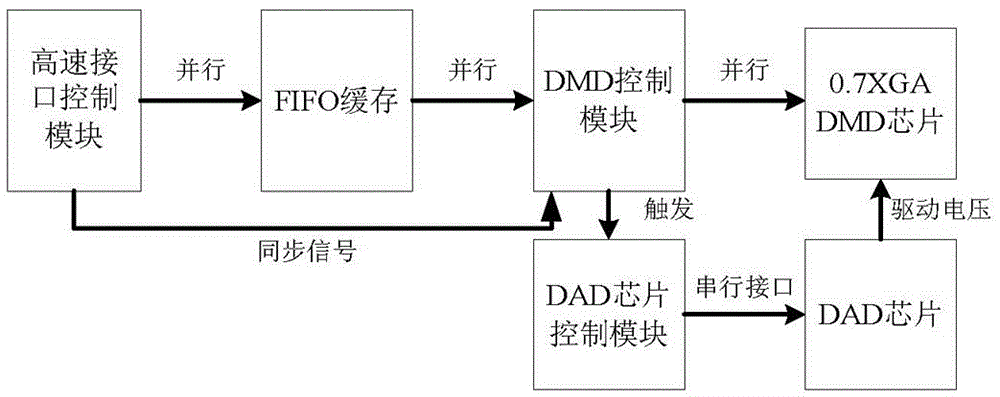

[0023] As a specific example, such as Figure 1 to Figure 3 As shown, a kind of multi-DMD splicing exposure system of the present invention comprises main frame, core control board, a plurality of DMD driver boards and DMD chip, and described main frame is connected with core control board by USB cable, and core control board and DMD The driver boards are connected through a parallel bus, and the DMD chip is connected to the DMD driver board.

[0024] The host is used to divide the binary image into multiple sub-images, number each sub-image, and send the sub-images to the core control board through the USB cable in sequence,

[0025] The core control board is used to receive the sub-image, and synchronously send the sub-image to multiple DMD driver boards through the parallel bus according to the serial number, and each DMD driver board receives a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com