Automatic clam-opening pearl-taking device

An automatic and positioning device technology, applied in fish farming, application, climate change adaptation, etc., can solve problems affecting pearl quality, dirty working environment, and large labor costs, so as to ensure success rate, reduce work intensity, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

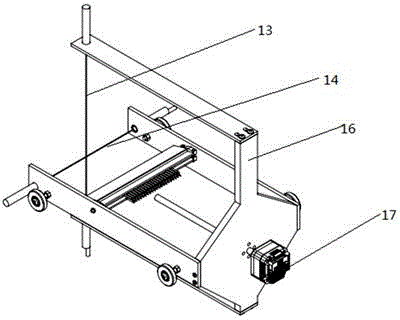

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

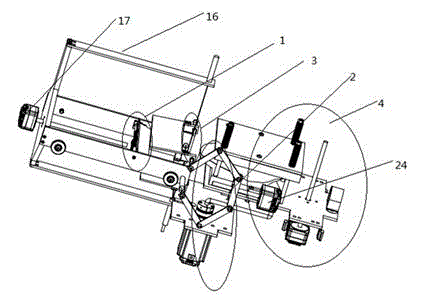

[0023] The automatic clam-opening and pearl-taking device for pearl mussels of the present embodiment, such as figure 1 As shown, the device includes a bracket 16, a second motor 17, a cutter assembly 1, an auxiliary baffle assembly 2, a positioning device 3, a clamp assembly 4, and a fourth motor 24. The bracket 16 may be a frame structure connected by rods.

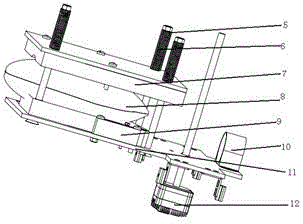

[0024] Such as figure 2 As shown, wherein the clamp assembly 4 includes a connecting rod 5, a telescopic spring 6, an upper splint 7, a lower splint 9, a rotary table 11, a first motor 12, a fourth motor 24, and the lower splint 9 is installed on one end of the frame 25, The lower end of the connecting rod 5 passes through the installation holes provided by the upper splint 7 and the lower splint 9 in order to connect the upper splint 7 and the lower splint 9 together, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com