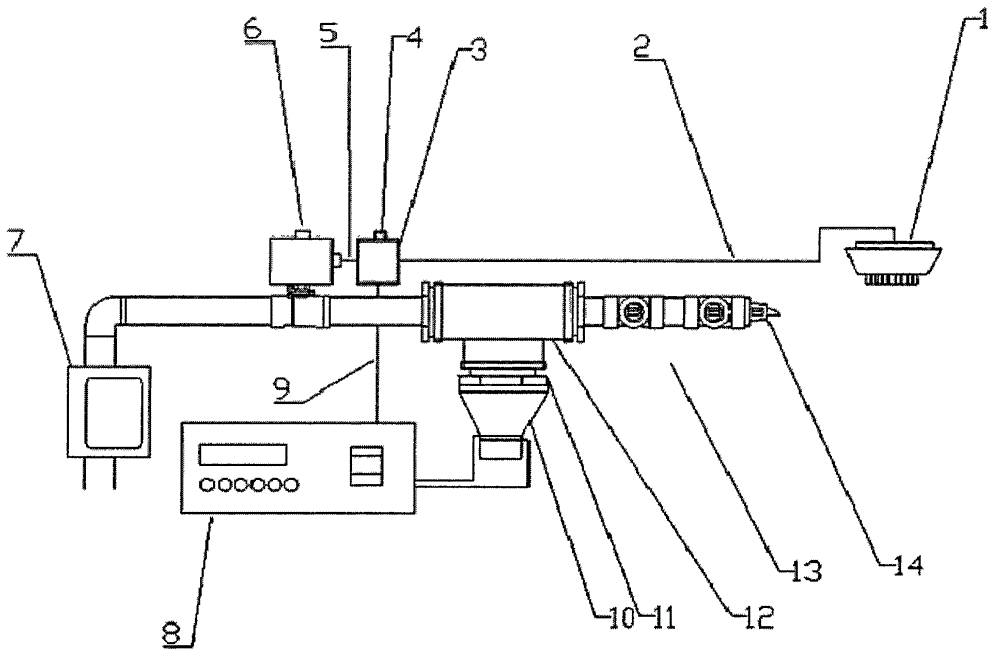

Ultrasonic device with enhanced atomizing, spraying, fire-extinguishing and smoke-reducing functions on basis of electric-high-frequency vibration conversion

A high-frequency vibration and atomization spray technology, applied in fire safety equipment and safety field, can solve the problems of changing the smoke and reducing the buoyancy of the smoke in the fire field, and achieve the effect of preventing re-ignition, good cooling performance and high fire extinguishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solution and advantages of the present invention clearer, the principle, structure and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. The scope of protection of the patent of the present invention is not limited to the following examples. For those skilled in the art, under the enlightenment of the patent of the present invention, it is possible to directly derive from the disclosure of this patent some basic deformations with the same principle, or the replacement of common known technologies in the prior art, and the same features. The simple replacement of technical features with different combinations and the same or similar technical effects all belong to the protection scope of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com