Waist-shaped deep hole processing method and prepared grouting block

A waist-shaped deep hole processing and grouting block technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as hole cracking, weld cracks, and difficulty in controlling the flatness of two notches, and achieve low cost , easy processing, and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

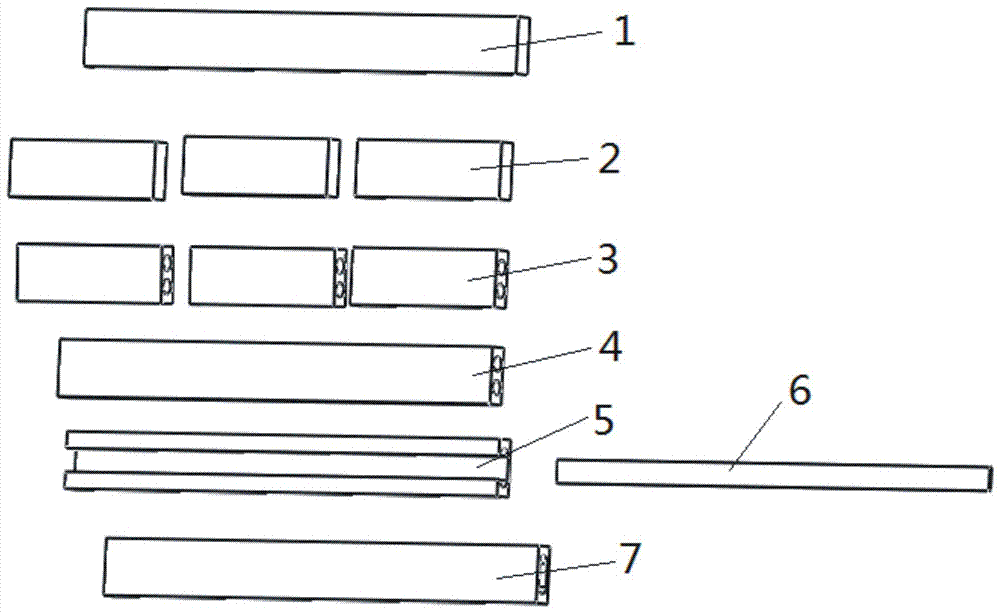

[0023] Such as figure 1 As shown, a kind of waist type deep hole machining method provided by the present embodiment comprises the following steps:

[0024] Step 1: cutting according to the shape of the workpiece to be processed to obtain the first semi-finished product 1;

[0025] Step 2: Decompose the first semi-finished product into several small pieces to obtain the second semi-finished product 2;

[0026] Step 3: Drill two through holes along the length direction of each second semi-finished workpiece to obtain a third semi-finished product 3;

[0027] Step 4: Weld and assemble each third semi-finished product sequentially. During the assembly process, insert each third semi-finished product into two through holes through two central shafts and connect them in series, so as to ensure the coaxiality of each hole, and obtain the first Four semi-finished products 4, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com