Steel tube inner wall rust removing device

A technology for the inner wall and rust of steel pipes, applied in the field of rust removal devices, can solve the problems of wasting water resources, limited effect, easy to rust, etc., and achieve the effects of reducing labor intensity, good effect and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

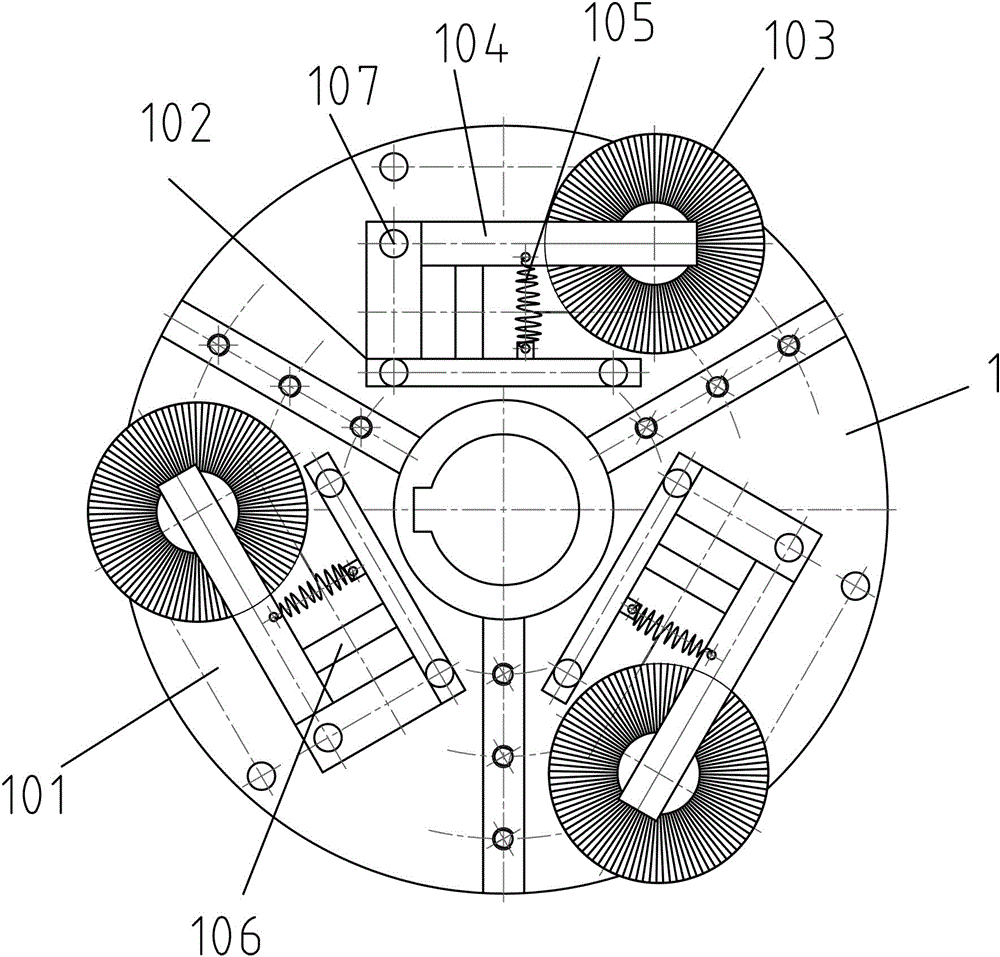

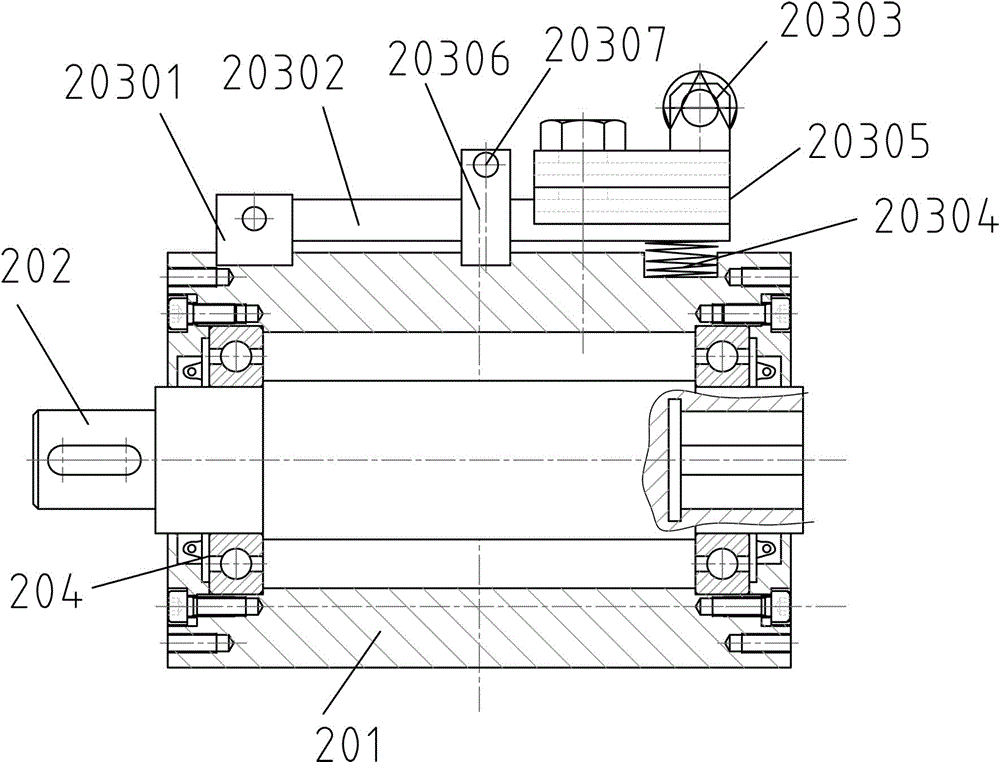

[0025] Embodiment 1: as figure 1 , 2 , 3, 4, and 5, the rust removal device for the inner wall of the steel pipe includes a support guide mechanism 1 in the pipe, a centrifugal polishing head 1 connected to the support guide mechanism 2 in the pipe and a support guide fixed in the pipe for removing rust. Mechanism 2 and a driving mechanism 3 for driving the centrifugal polishing head 1 to rotate; the driving mechanism 3 includes a motor, which is fixed on the support guide mechanism 2 in the tube, and is used to drive the centrifugal polishing head 1 to rotate, and the centrifugal polishing head 1 Complete the removal of rust on the inner wall of the steel pipe.

[0026] The centrifugal polishing head 1 includes a mounting plate 101, at least three mounting brackets 102 all arranged on the mounting plate 101, a connecting arm 104 whose one end is hinged on the mounting bracket 102 and the other end is equipped with a polishing wheel 103 , the extension spring 105 arranged be...

Embodiment 2

[0029] Embodiment 2, attached Figure 6 , suitable for use in a fixed place; the support and guide mechanism is the one connected with the rigid sleeve 4, and the motor is fixed on the driving trolley, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com