Novel four-axis robot control system

A four-axis robot and control system technology, applied in the field of robotics, can solve problems such as simplicity and inability to meet the multi-function of robots, and achieve the effect of flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with specific embodiments.

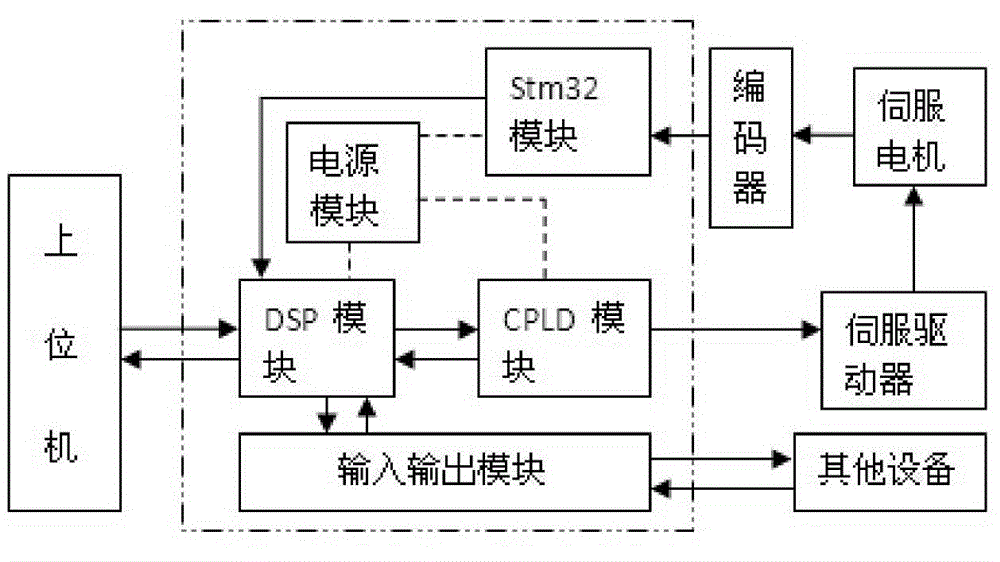

[0016] The present invention is a kind of control system that realizes PTP motion control (point position control); figure 1 Shown, the system of the present invention comprises host computer, motion control system, servo drive, servo motor, encoder; It is composed of logic device, stm32 module (ARM Cortex-M3 core), input and output module, and power supply module; the motion control system realizes the control of the robot according to the motion information sent by the host computer.

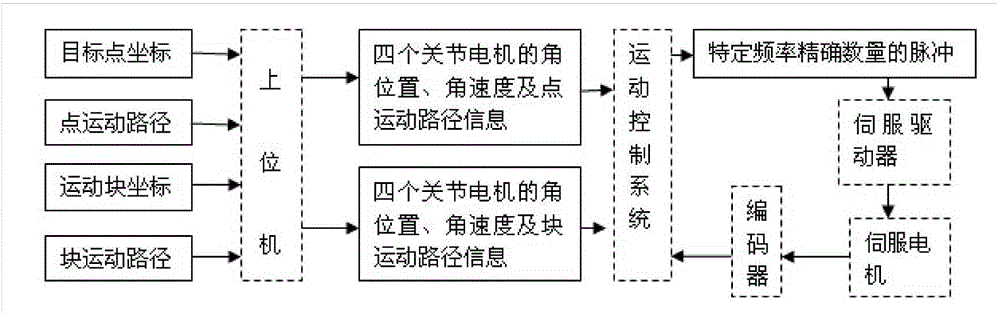

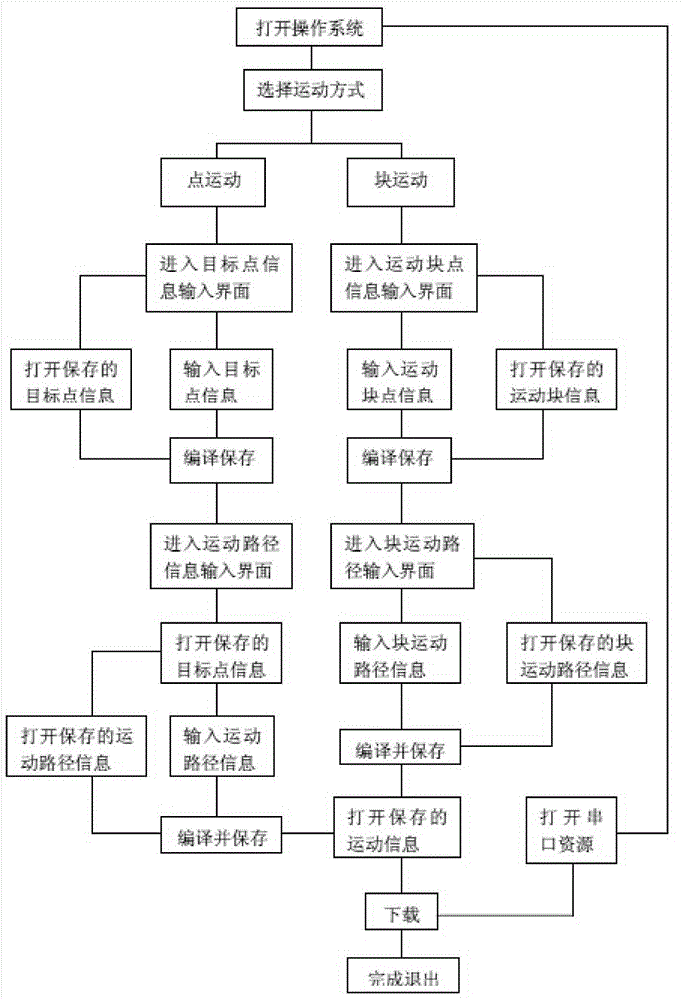

[0017] Such as figure 2 For the transmission of control information shown, set parameters in the host computer, such as target point coordinates, point motion path, motion block coordinates and block motion path, and the host computer converts the input parameters into the operating data of the servo motor on the robot joint, The operating data of the servo motor includes the angular v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com