Method for distributing ceramic tiles and brick transferring mechanism applied to method

A technology for ceramic tiles and fabrics, applied in the field of ceramic tile production, can solve problems such as obstacles, inability to guarantee the effect of pressing and molding of ceramic tiles, and easy scattering of green brick fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiment:

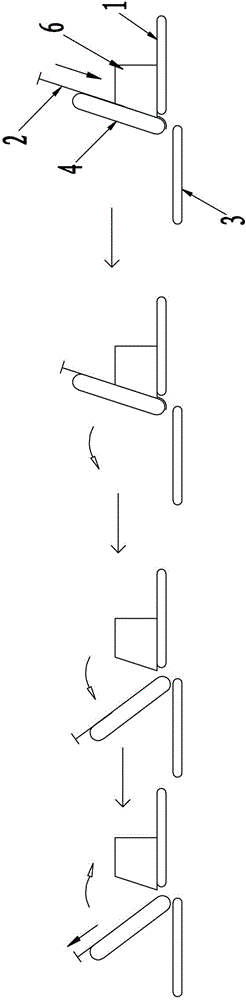

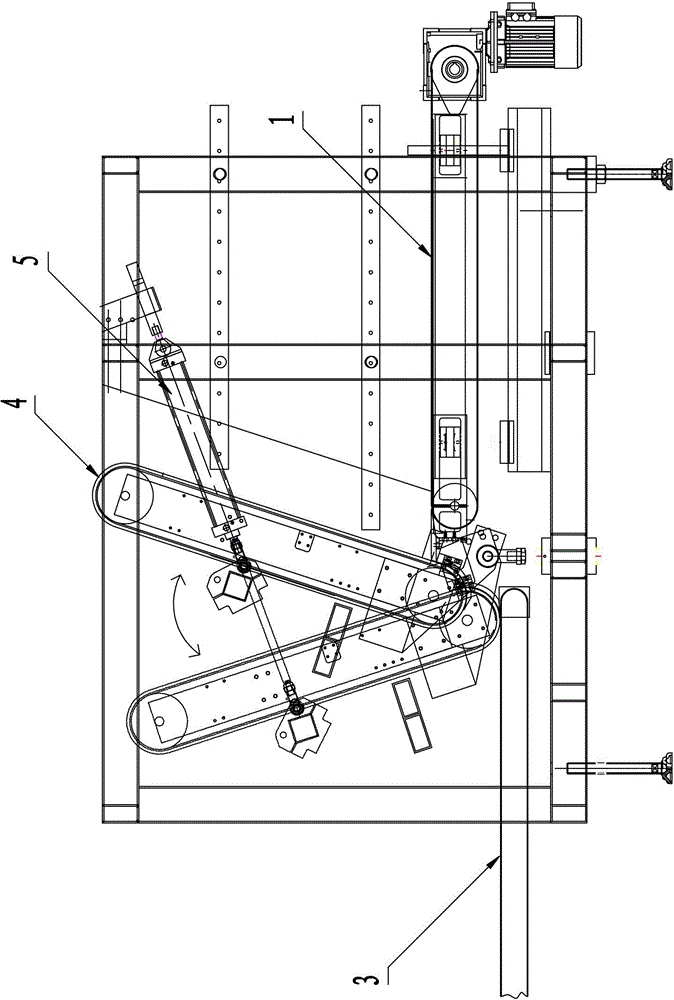

[0012] See attached figure 1 As shown, the ceramic cloth method described in this embodiment is as follows: first sprinkle the fabric on the conveyor belt 1 to form a relatively thick fabric pile 6, and then add thread materials to the fabric pile 6 according to production needs, so that the fabric The pile 6 has the desired texture effect; then the pile of fabrics 6 is moved to the cutting station for cutting under the action of the conveyor belt 1, wherein before the pile of fabrics 6 is cut, the front end of the pile of fabrics 6 (that is, one end in the forward direction of the pile of fabrics) Fitting with a transfer conveyor belt 4 provided with a groove for forming the required cut brick thickness, the fabric at the front end of the pile of fabrics 6 is located in the groove, so that the fabric in the groove forms a blank brick prototype ; Subsequently, the cutter 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com