Pneumatic conveying system of fly ash of dust collector

A technology of pneumatic conveying system and dust collector, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc. It can solve the problems of heavy operation and maintenance workload, low system operation reliability, complex system configuration, etc., and achieve maintenance Small amount, low annual operation and maintenance costs, and low system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

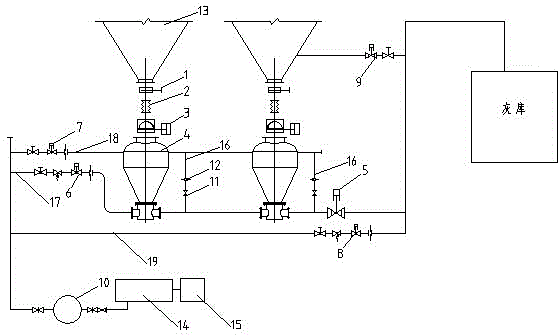

[0027] As shown in the figure, a dust collector fly ash pneumatic conveying system, which includes a conveying device 01, an air source device 02, and a pipeline device 03, and the conveying device 01 is connected to the air source device 02;

[0028] The conveying device 01 is composed of a manual inspection door 1, an expansion joint 2, a feed valve 3, an NPT transmitter 4, a discharge valve 5, an intake valve group 6, an air supply valve group 7, an auxiliary blow valve group 8, a blower Blocking valve group 9; the manual inspection door 1 is located at the bottom of the dust collector hopper 13; the expansion joint 2 is connected to the bottom of the manual inspection door 1, and the NPT transmitter 4 is connected to the bottom of the expansion joint 2 , the top of the NPT transmitter 4 is provided with a feed valve 3, one side of the bottom is connected to a discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com