Water production control method, water production control device and ultra-pure water preparation system based on electric ball valves adjustment

A technology of electric ball valve and preparation system, which is applied in the direction of electrical program control, water/sewage treatment equipment, program control in sequence/logic controller, etc., which can solve the problems of reducing cost and improving control accuracy, and achieves improved production. Water control process and method, prolonging the service life and improving the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the description and drawings therein are used for illustration in essence, rather than for limit the invention.

[0029] The water production control method of the embodiment of the present invention is applicable to the water production control device of the embodiment of the present invention, and is also applicable to the ultrapure water preparation device of the embodiment of the present invention.

[0030] The ultrapure water preparation system of the embodiment of the present invention has the water production control device of the embodiment of the present invention.

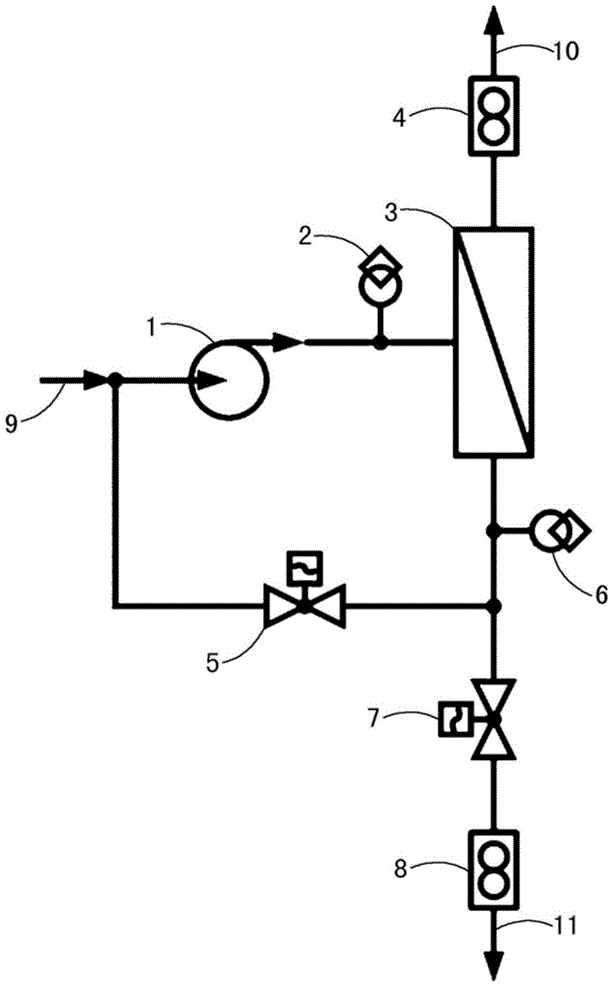

[0031] figure 1 It is a schematic structural diagram of an ultrapure water preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com