Decorative sheet and decorative resin formed product prepared by using same

A decorative sheet, curable resin technology, applied in coatings, polycarbonate coatings, polyurea/polyurethane coatings, etc., can solve the problems of complicated conditions, poor economy, difficult curing treatment, etc., and achieve good scratch resistance, The effect of easy three-dimensional forming and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~4

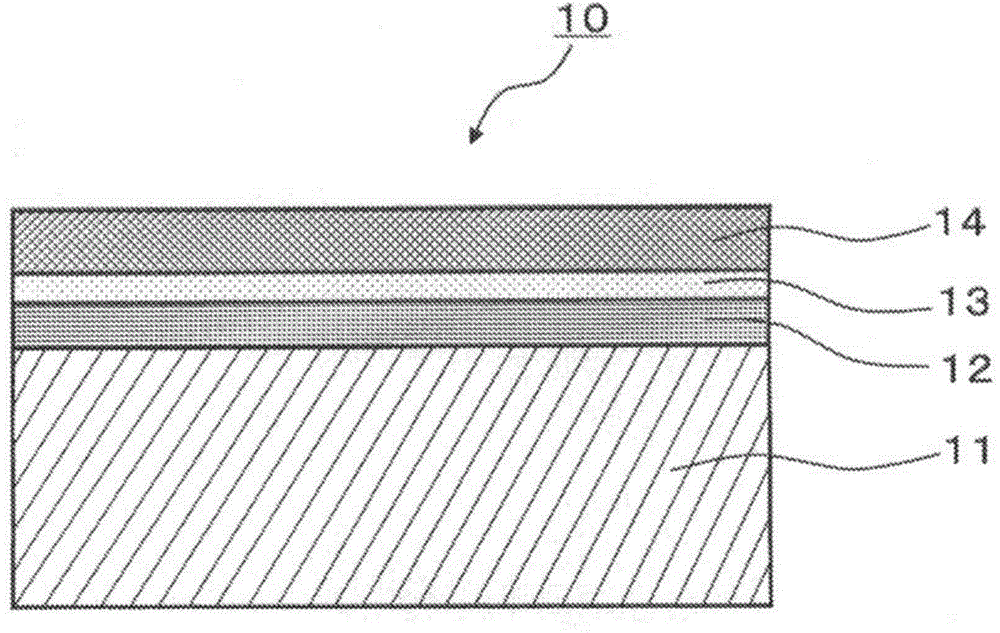

[0173] An ABS resin film (flexural modulus of elasticity; 2000 MPa, thickness: 400 μm) was used as a base material, and a pattern layer of a woodgrain pattern was formed by gravure printing on the surface of the film using an acrylic resin ink. Next, the surface of the pattern layer is coated with acrylic polyol and hexamethylene diisocyanate (hexamethylene diisocyanate is compounded in such a way that the NCO equivalent is the same as the OH equivalent of the acrylic polyol) by the gravure reverse coating method. The primer layer composed of the primer composition. The thickness of the primer layer was 3 μm.

[0174] Next, an electron beam curable resin composition having a composition shown in Table 1 was applied by gravure coating on the surface of the primer layer so that the cured thickness (μm) of the resin composition became the value shown in Table 1. The uncured resin layer was irradiated with electron beams at an accelerating voltage of 165 kV and an irradiation dos...

Embodiment 8~12 and comparative example 5~8

[0185] An ABS resin film (flexural modulus of elasticity; 2000 MPa, thickness: 400 μm) was used as a base material, and a pattern layer of a woodgrain pattern was formed by gravure printing on the surface of the film using an acrylic resin ink. Next, the surface of the pattern layer is coated with acrylic polyol and hexamethylene diisocyanate (hexamethylene diisocyanate is compounded in such a way that the NCO equivalent is the same as the OH equivalent of the acrylic polyol) by gravure reverse coating. A primer layer comprising the primer composition. The thickness of the primer layer was 3 μm.

[0186] Next, an electron beam curable resin composition having a composition shown in Table 2 was applied by gravure coating on the surface of the primer layer so that the cured thickness (μm) of the resin composition became the value shown in Table 2. The uncured resin layer was irradiated with an electron beam having an accelerating voltage of 165 kV and an irradiation dose of 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com