Grease resisting and freezing resisting printing ink

An anti-freeze and ink technology, applied in ink, household utensils, applications, etc., can solve the problems of high cost, limited applicable pigments, limited anti-freeze performance, etc., and achieve low cost, wide range of applicable colors, good oil resistance and freezing resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Blend 250g of DSM394 polyurethane resin, 70g of 1 / 16s nitrocellulose, 30g of 1 / 8s nitrocellulose, 20g of castor oil, 50g of MONENG-3060 dispersant, 50g of IA10 chelate and 80g of DIC5711 red pigment in 300g of ethanol In the mixed solution of 150g ethyl acetate, concentrate and thicken, extrude into color chips, add 300g ethanol and 150g ethyl acetate mixed solution to disperse into ink after the color chips are crushed, apply the ink to the surface of the printed matter, and test after drying .

Embodiment 2

[0020] 300g of DSM394 type polyurethane resin, 60g of 1 / 16s nitrocellulose, 40g of 1 / 8s nitrocellulose, 30g of castor oil, 80g of MONENG-3060 type dispersant, 80g of AA75 type chelate and 120g of P-HRE yellow pigment were blended in In the mixed solution of 145g ethanol and 145g ethyl acetate, concentrate and thicken and extrude into color chips, add 145g ethanol and 145g ethyl acetate mixed solution to disperse into ink after the color chips are crushed, apply the ink to the surface of the printed matter, and dry it carry out testing.

Embodiment 3

[0022] DSM394 polyurethane resin 270g, 1 / 16s nitrocellulose 64g, 1 / 8s nitrocellulose 36g, castor oil 25g, MONENG-3060 dispersant 55g, IA10 chelate 30g, AA75 chelate 30g and PB15: 4 100g of blue pigment is blended in the mixed solution of 130g ethanol and 260g ethyl acetate, extruded into colored flakes after concentrating and thickening, and the mixed solution of 130g ethanol and 260g ethyl acetate is dispersed into ink after the colored flakes are pulverized. The ink is applied to the surface of the print and tested after it dries.

[0023] Ink performance test:

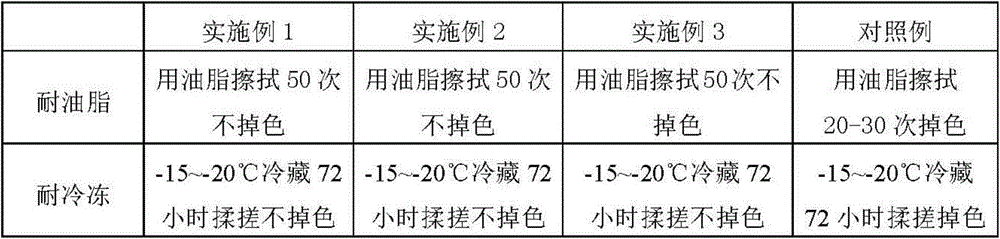

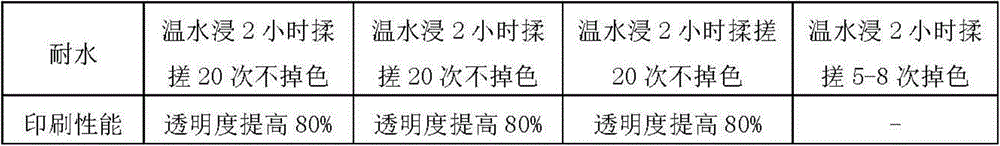

[0024] The inks of Examples 1-3 were subjected to relevant performance tests, and the ink described in CN103613994A was used as a control example. The specific results are shown in Table 1.

[0025] Table 1 ink performance test:

[0026]

[0027]

[0028] It can be seen from Table 1 that the inks of Examples 1-3 are better in grease resistance, freezing resistance, and warm water resistance than those of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com