Preparation method of polyurethane pressure-sensitive adhesive composition and polyurethane protective film

A polyurethane, pressure-sensitive adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the difficulty of matching adhesives and antistatic agents, low pollution performance of protective films, and reduce film adhesion. It can improve the low pollution performance, extend the operating time, and achieve the effect of good surface adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

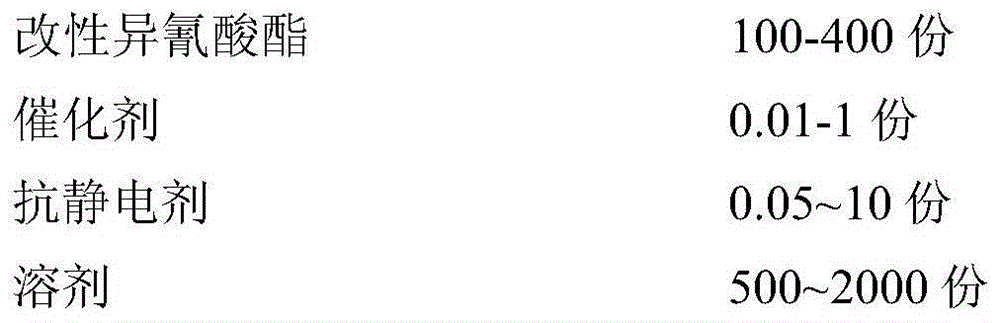

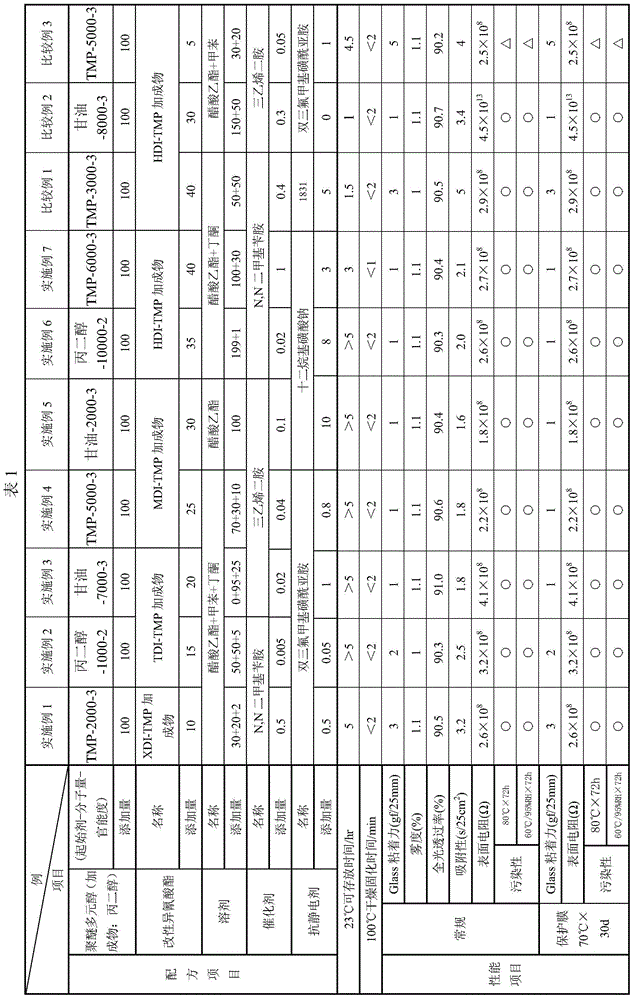

[0028] The formulas of polyurethane pressure-sensitive adhesives in Example 1 to Example 7 and Comparative Example 1, Comparative Example 2, and Comparative Example 3 are shown in Table 1.

[0029] TMP in the table is the abbreviation of trimethylolpropane,

[0030] Among them, the polyurethane in Examples 1 to 7 mixes the above-mentioned formula raw materials in a pre-stirring container in proportion, fully stirs for 30 minutes, and then sets aside. After the bubbles disappear, it is filtered through a filter with a pore size less than or equal to 3 μm to remove impurities in the solvent. Use a scraper Type coating method according to 15±3g / m 2 The amount of wet glue is coated on a 50μm thick PET substrate, dried in an oven at 100°C for 2 minutes, cooled to room temperature, pasted with a 50μm release film and rolled; then placed in a constant temperature room at 40°C for 7 days, and divided into The processed finished products are made of polyurethane protective film produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com