Full grouting sleeve for connecting steel bars

A technology for grouting sleeves and connecting sleeves, applied in structural elements, building components, building reinforcements, etc., can solve problems such as restricting the application or technological development of prefabricated frame structures, and achieve high processing costs, reduced production and processing difficulties, The effect of improving project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

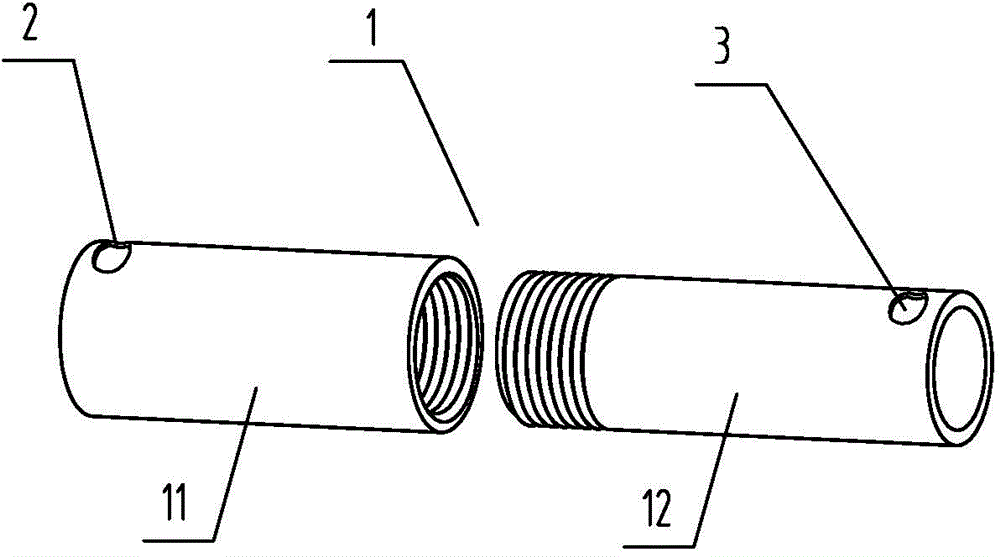

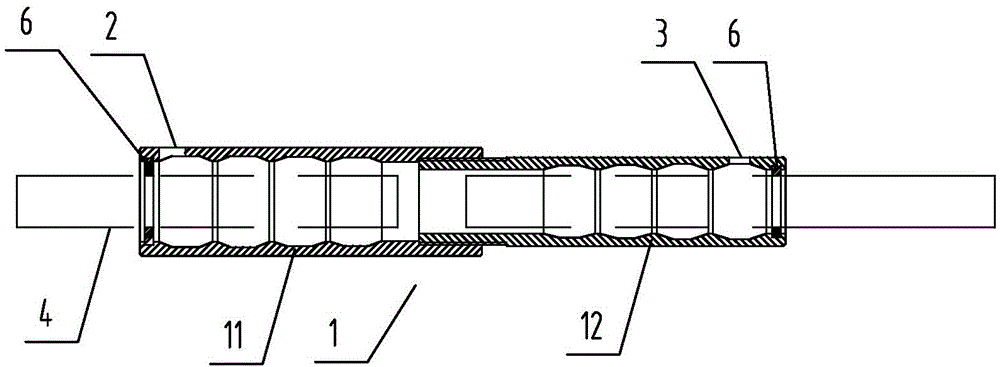

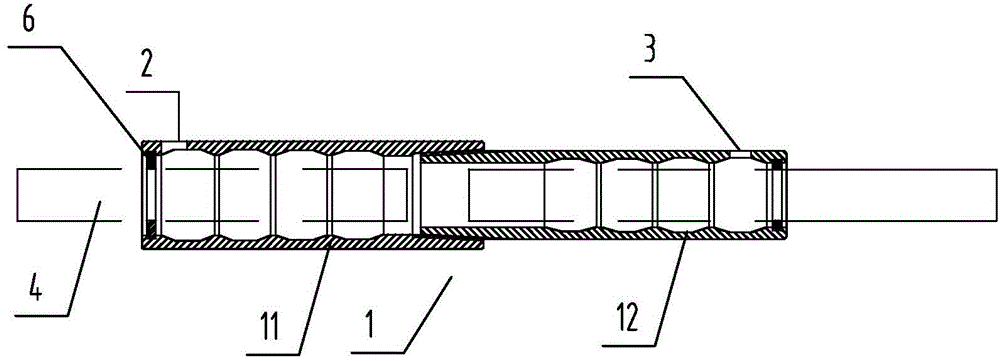

[0029] like figure 1 , 4 As shown in and 9, the full grouting sleeve 1 for steel bar connection in this embodiment includes two sections of grouting sleeves, which are respectively the first grouting sleeve 11 and the second grouting sleeve 12, the first grouting sleeve 11 or the second grouting sleeve The grouting tube 12 is provided with a grouting hole 2, and the two sections of the grouting sleeve are connected by threads or through the connecting sleeve 5, and the two sections of the grouting sleeve are respectively poured into the first grouting sleeve 11 and the second grouting sleeve 12. The grouting material is fixedly connected with the connected steel bar 4 .

[0030] like Figure 1-3 As shown, the outer diameters of the two sections of grouting sleeves are different, the outer diameter of the first grouting sleeve 11 is larger than the outer diameter of the second grouting sleeve 12, and the two sections of grouting sleeves are connected by straight threads or tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com