Coiled tubing underground load testing tool

A technology of load testing and tubing, applied in measurement, wellbore/well components, construction, etc., can solve the problems of difficult real-time detection of the force of the pipe string, and achieve the effect of improving the understanding of mechanical behavior and the level of tool design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

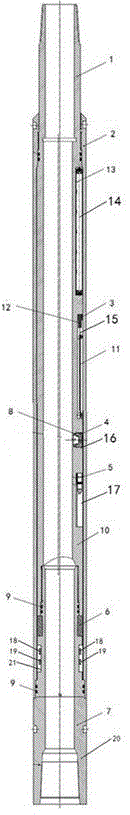

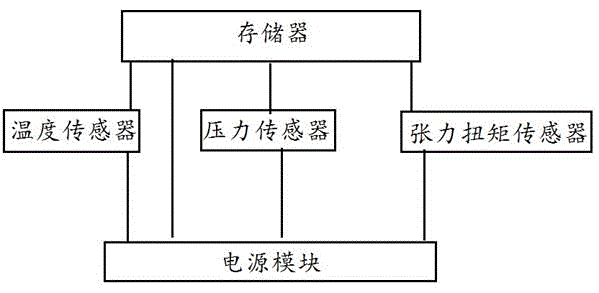

[0024] like figure 1 and figure 2 As shown, the present invention provides a coiled tubing downhole load testing tool, comprising an inner cylinder 10 and an outer casing 2 fixedly sleeved on the outer surface of the inner cylinder 10, the upper end of the inner cylinder 10 is an upper joint 1, and the inner cylinder 10 The lower end is threadedly connected with a tension torque sensor 7, and a sealing ring 9 is provided between the lower end of the outer casing 2 and the tension torque sensor 7; a power supply module 13, a memory 11, a temperature Sensor 12, pressure sensor 8 is arranged on the inner cylinder wall of inner cylinder 10, tension torque sensor 7, temperature sensor 12, pressure sensor 8, memory 11 are connected with power supply module 13 respectively, tension torque sensor 7, temperature sensor 12, pressure sensor 8 are respectively connected with the memory 11.

[0025] Specifically, during coiled tubing fracturing, drilling, and workover operations, check ...

Embodiment 2

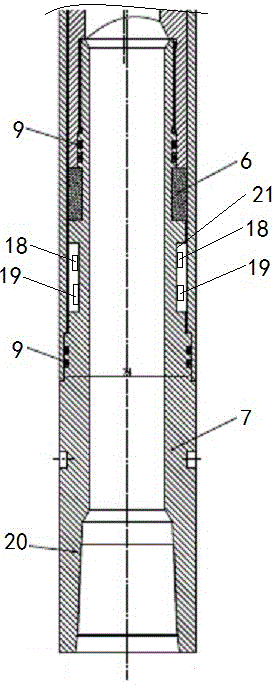

[0029] The invention provides a coiled tubing downhole load testing tool, comprising an inner cylinder 10 and an outer casing 2 fixedly sleeved on the outer surface of the inner cylinder 10, the upper end of the inner cylinder 10 is an upper joint 1, and the lower end of the inner cylinder 10 is threaded There is a tension torque sensor 7, a sealing ring 9 is arranged between the lower end of the outer casing 2 and the tension torque sensor 7; a power module 13, a memory 11, and a temperature sensor 12 are arranged between the inner casing 10 and the outer casing 2, The inner cylinder wall of the inner cylinder 10 is provided with a pressure sensor 8, the tension torque sensor 7, the temperature sensor 12, the pressure sensor 8, and the storage device 11 are respectively connected with the power supply module 13, and the tension torque sensor 7, the temperature sensor 12, and the pressure sensor 8 are connected with the power supply module 13 respectively. Memory 11 is connecte...

Embodiment 3

[0034] The invention provides a coiled tubing downhole load testing tool, comprising an inner cylinder 10 and an outer casing 2 fixedly sleeved on the outer surface of the inner cylinder 10, the upper end of the inner cylinder 10 is an upper joint 1, and the lower end of the inner cylinder 10 is threaded There is a tension torque sensor 7, a sealing ring 9 is arranged between the lower end of the outer casing 2 and the tension torque sensor 7; a power module 13, a memory 11, and a temperature sensor 12 are arranged between the inner casing 10 and the outer casing 2, The inner cylinder wall of the inner cylinder 10 is provided with a pressure sensor 8, the tension torque sensor 7, the temperature sensor 12, the pressure sensor 8, and the storage device 11 are respectively connected with the power supply module 13, and the tension torque sensor 7, the temperature sensor 12, and the pressure sensor 8 are connected with the power supply module 13 respectively. Memory 11 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com