High-pressure water injection device and its construction method for relieving the risk of fracture-slip rockburst

A high-pressure, rockburst technology, applied in mining equipment, earth-moving drilling, wellbore/well components, etc., can solve the problems of reducing stress or energy concentration, high technical difficulty, and high risk control difficulty, so as to ensure construction safety, The effect of reducing the risk of rock burst and reducing the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

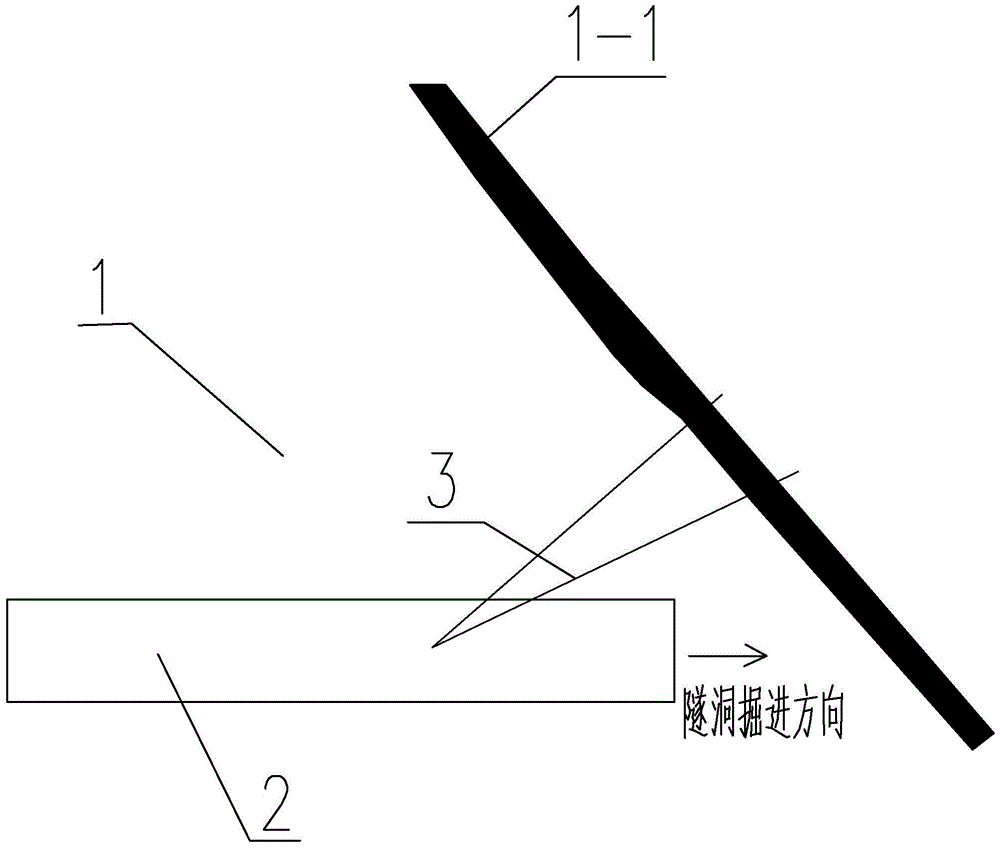

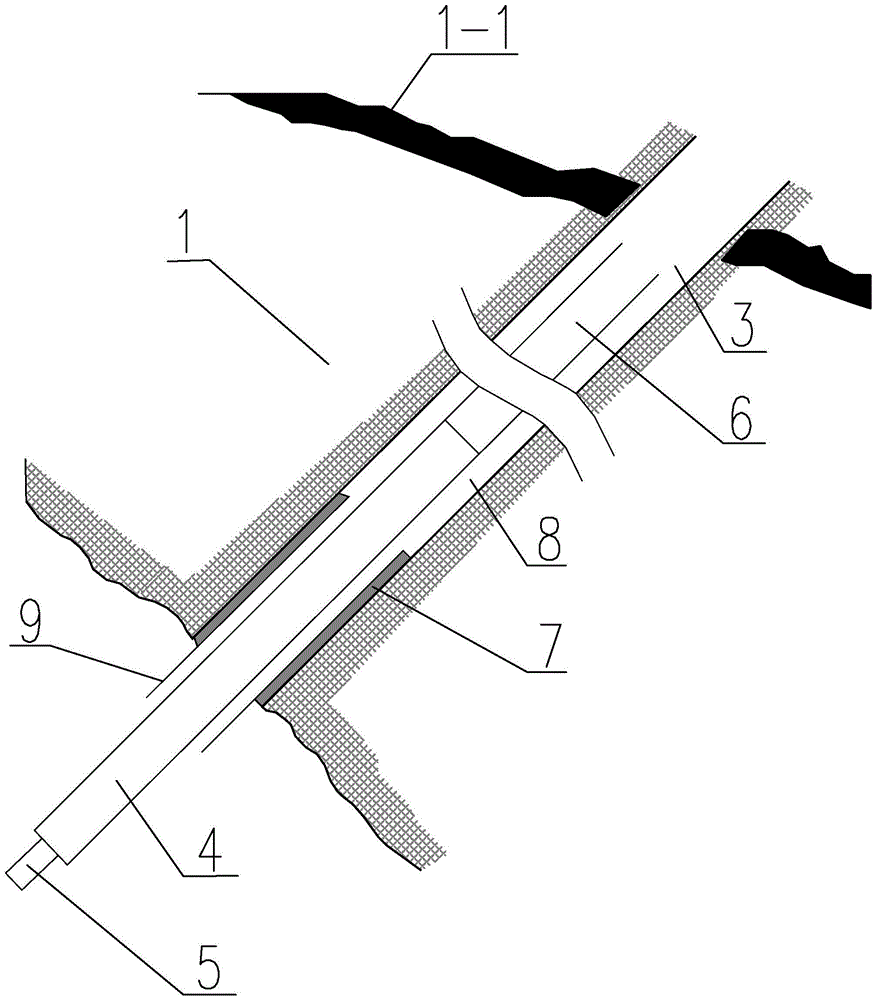

[0021] Such as figure 1 , figure 2 As shown, this embodiment is a high-pressure water injection device that relieves the risk of fracture-slip rockburst, including surrounding rock 1, excavation tunnel 2, water injection borehole 3, high-pressure water injection steel pipe 4, water inlet pipe interface 5, casing 6, Sealing rubber ring 7, cement slurry 8 and positioning ring 9.

[0022] In this embodiment, there is a horizontal excavation tunnel 2 in the deeply buried underground surrounding rock 1, and there is an oblique fault zone 1-1 at an angle of 40 to 45 degrees with the horizontal direction in front of the excavation of the tunnel. The risk of rockburst, in this example, two water injection boreholes 3 with a diameter of 60 mm and basically perpendicular to the fault zone are drilled from the excavation tunnel 2 to the fault zone 1-1 of the surrounding rock 1. The total length of the water injection boreholes should not exceed 20m and Pass through the fracture zone f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com