Determining the timing and method of excavation from opposite direction to one direction before the breakthrough of deep hard rock tunnel

A determination method and technology for tunnels, which are applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as non-technical operation plans, and achieve the effect of reducing the risk of rock-pillar rockburst, making the operation feasible, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for determining the timing and method of changing from one direction to one direction before the breakthrough of a deep buried hard rock tunnel, the method is carried out according to the following steps:

[0029] 1) When the distance between two facing tunnel faces is 5 times the tunnel diameter, at least 4 microseismic sensors shall be arranged behind each tunnel face to monitor the microseismic occurrence of rock mass near the two tunnel faces during the opposite tunneling process. The micro-vibration signal produced at the time of rupture. The microseismic sensor is embedded and installed through drilling, and is fixedly coupled with the rock mass. The embedded depth must exceed the relaxation depth of the surrounding rock. The layout scheme of microseismic sensors should be conducive to the acquisition of microseismic signals by microseismic sensors and the positioning of microseismic sources. The distance between the microseismic sensor and the working f...

Embodiment 2

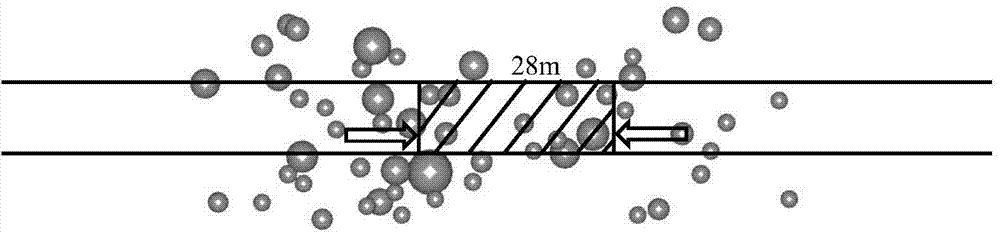

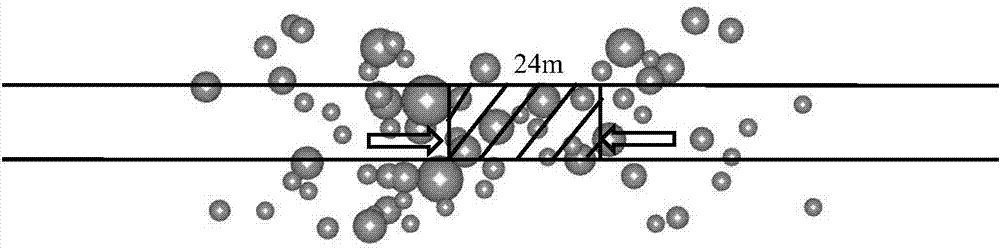

[0040] The through-hole section of a deep-buried facing tunnel is 2500m deep, the lithology is hard and compact marble, and the tunnel diameter is 12m. figure 1 . The relaxation depth of surrounding rock is within 3m.

[0041]1) When the distance between the two tunnel faces is 5 times the tunnel diameter, that is, 60m, 6 microseismic sensors are arranged near the section 60m behind each tunnel face to monitor the rupture of the two tunnel faces and the surrounding rock mass Generated micro-vibration signal. The microseismic sensor is embedded and installed through drilling, and the embedded depth is 5m, which exceeds the relaxation depth of the surrounding rock. Grouting is injected into the hole, so that the microseismic sensor is fixedly coupled with the rock mass. There should be a certain distance between the microseismic sensor and the working face to prevent damage to the microseismic sensor caused by excavation of the working face if the distance is too close, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com