Opening and closing control method of a barrel valve

A control method and barrel valve technology, applied in the direction of safety devices, machines/engines, mechanical equipment, etc., can solve problems such as structural incomplete balance, pressure imbalance, high pressure, etc., to eliminate structural stress, reduce the number of adjustments, The effect of small displacement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] This embodiment provides an opening and closing control method for a cylinder valve of a hydropower station, which includes the following steps:

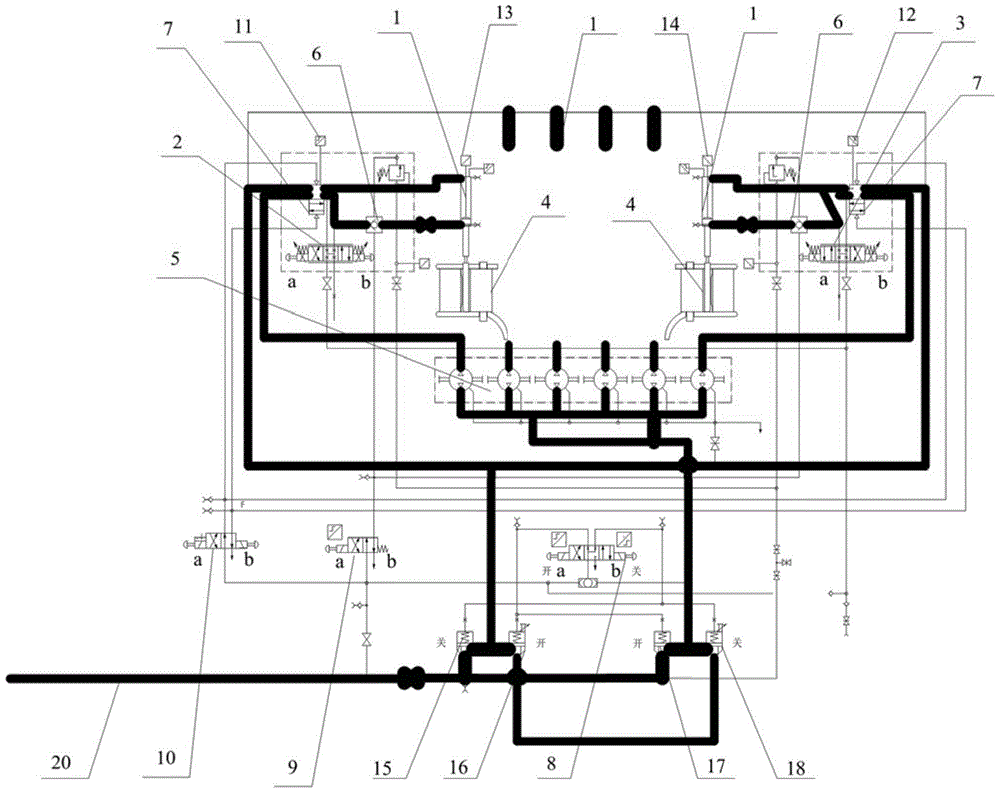

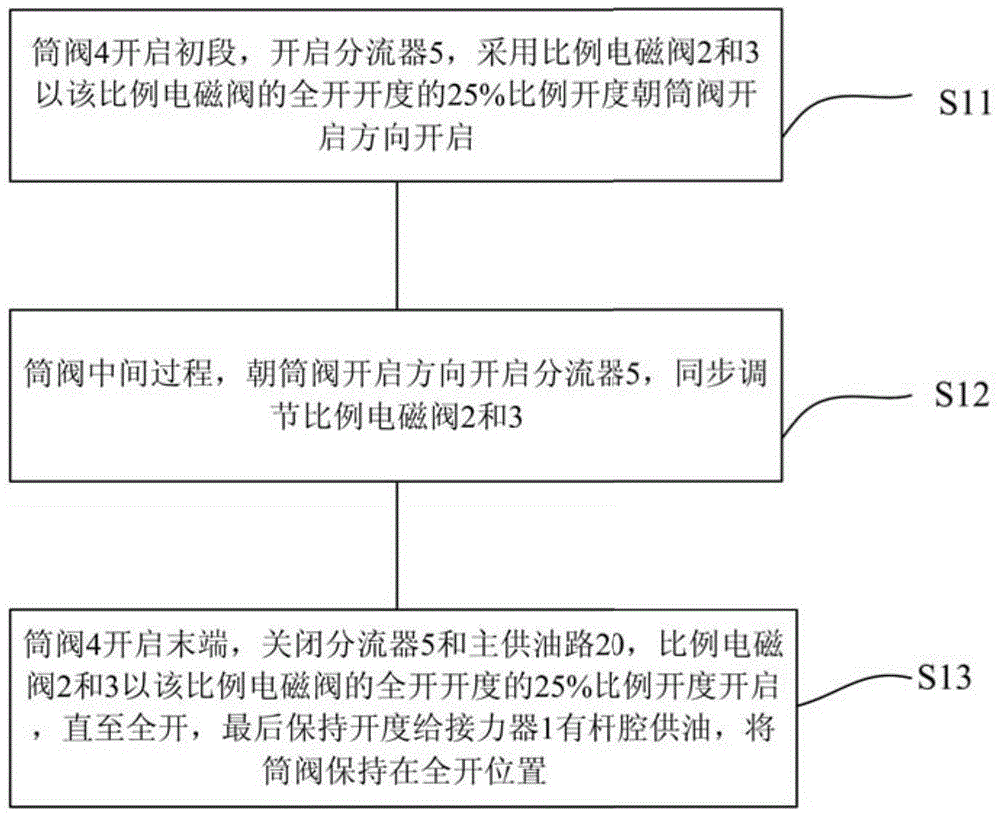

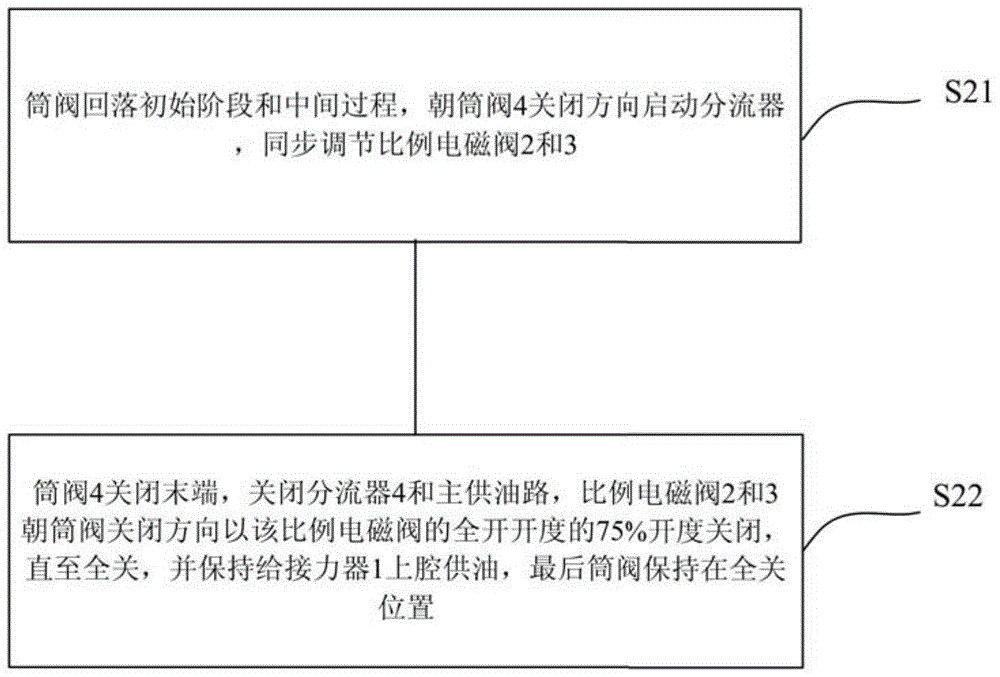

[0036] S1 as figure 1 As shown, in the opening process of the barrel valve 4, the delay flat pressure operation is first performed on the barrel valve 4, and then when the barrel valve 4 is lifted to full opening, the proportional solenoid valves 2 and 3 are used for synchronous adjustment, and the barrel valve 4 Fully open remains in the fully open position. The drive system of the barrel valve is provided with six servomotors 1, which are controlled by a hydraulic system. In this embodiment, the cylinder valve electric control cabinet is used to control the six servomotors 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com