Multi-heat source module frequency conversion antifreeze anticorrosion heat exchanger and heat exchange method

A heat exchanger, multi-heat source technology, applied in heating methods, household heating, household heating and other directions, can solve problems such as pollution, energy waste and environment, and achieve the effect of cleaning the environment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

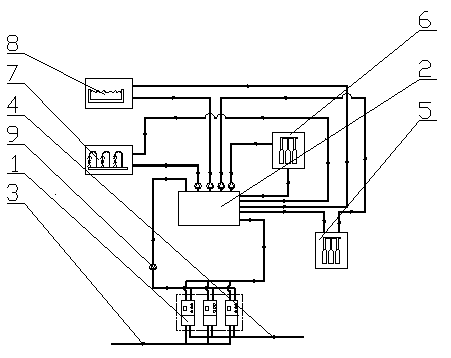

[0013] A multi-heat source module frequency conversion anti-freezing and anti-corrosion heat exchanger, which consists of: a heat exchange unit 1, one end of the heat exchange unit is connected to an expansion tank 2 through a tube bundle, and the other end of the heat exchange unit is connected to tap water cooling water through a tube bundle The water inlet pipe 3 is connected with the tap water hot water outlet pipe 4, and the expansion tank is respectively connected with the coal-fired heat source 5, the flue gas heat source 6, the steam heat source recovery device 7, and the sewage heat source pool 8 through the tube bundle.

Embodiment 2

[0015] According to the multi-heat source module frequency conversion antifreeze and anticorrosion heat exchanger described in Embodiment 1, the expansion water tank is respectively equipped with a frequency conversion water pump in the tube bundle circuit connected to the coal-fired heat source, the flue gas heat source, the steam heat source recovery device, and the sewage heat source pool 9. The antifreeze outlet pipe of the heat exchange unit is connected to the expansion tank through a frequency conversion water pump.

Embodiment 3

[0017] According to the heat exchange method of the multi-heat source module frequency conversion type antifreeze and anticorrosion heat exchanger described in embodiment 1 or 2, the heat source heat exchanger in the heat exchange unit recovery system can efficiently extract the heat of sewage, waste gas, and flue gas respectively, and convert the heat Absorbed into the brine, and sent to the expansion tank by the heat pump for concentration, the brine with heat in the expansion tank is sent to the frequency conversion heat exchange unit under the delivery of the heat pump, and the heat in the refrigerant is transferred through the condenser, including The heat energy generated by the power consumption during the operation of the heat pump unit is transferred to the tap water supply system to form heat recycling. The recovered heat accounts for about 85% of the heat required by the heated hot water. At the same time, the sewage is reduced to 5 ℃, avoiding the formation of therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com