Full free-flying wind tunnel test mechanism for sub-cluster separation

A technology of wind tunnel test and submunition, which is applied in the field of aerospace engineering, can solve the problems that the size of the wind tunnel of the ejection mechanism of the model cannot be increased, it is difficult to control the ejection speed and angular velocity of the model, and it is difficult to realize the full free flight test, etc., so as to achieve a compact structure , reliable performance, and the effect of free movement of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

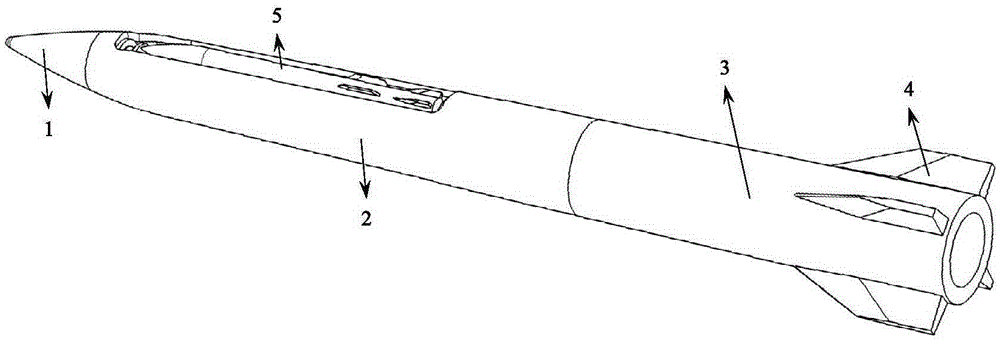

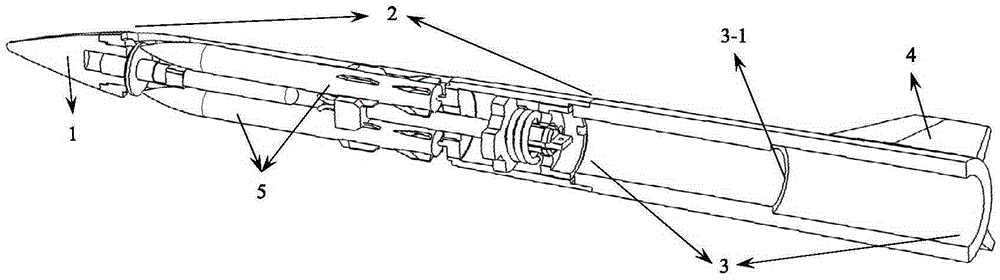

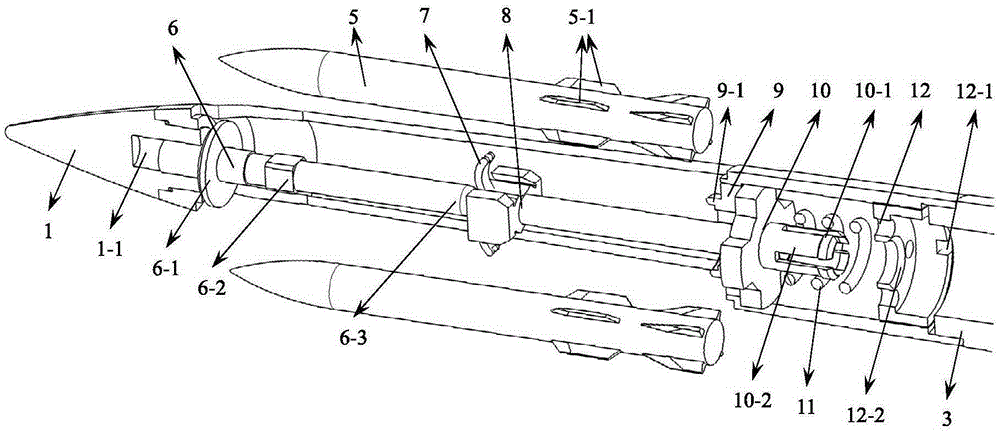

[0032] see Figure 1 to Figure 6As shown, 1 is the head of the female bullet, which has a threaded hole 1-1, and the blocking rod 6 is connected with the threaded hole 1-1 of the female bullet through threads. There is a positioning plate 6-1 on the blocking rod 6, and the positioning plate 6-1 can limit the axial forward movement of the bullet along the parent bullet, and plays the role of positioning; there is a square platform 6-2 on the blocking rod, and the square platform is beneficial to the blocking rod. The 6 installations; the blocking rod curved surface head 6-3 is arranged on the blocking rod 6, and the head of the blocking rod curved surface head 6-3 has many forms, including a spherical head, an elliptical ball head, a parabolic ball head and the like. The bullet head 1 is connected to the middle part 2 of the bullet through threads, and the rear part 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com