Crack prefabricating device of non-metal material fracture toughness test

A non-metallic material, fracture toughness technology, applied in the field of non-metallic material fracture toughness test, can solve the problems of non-metallic materials such as low strength, temperature sensitivity, long preparation cycle, etc., to reduce prefabrication time and reduce unqualified products rate, the effect of increasing the test rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is described in further detail:

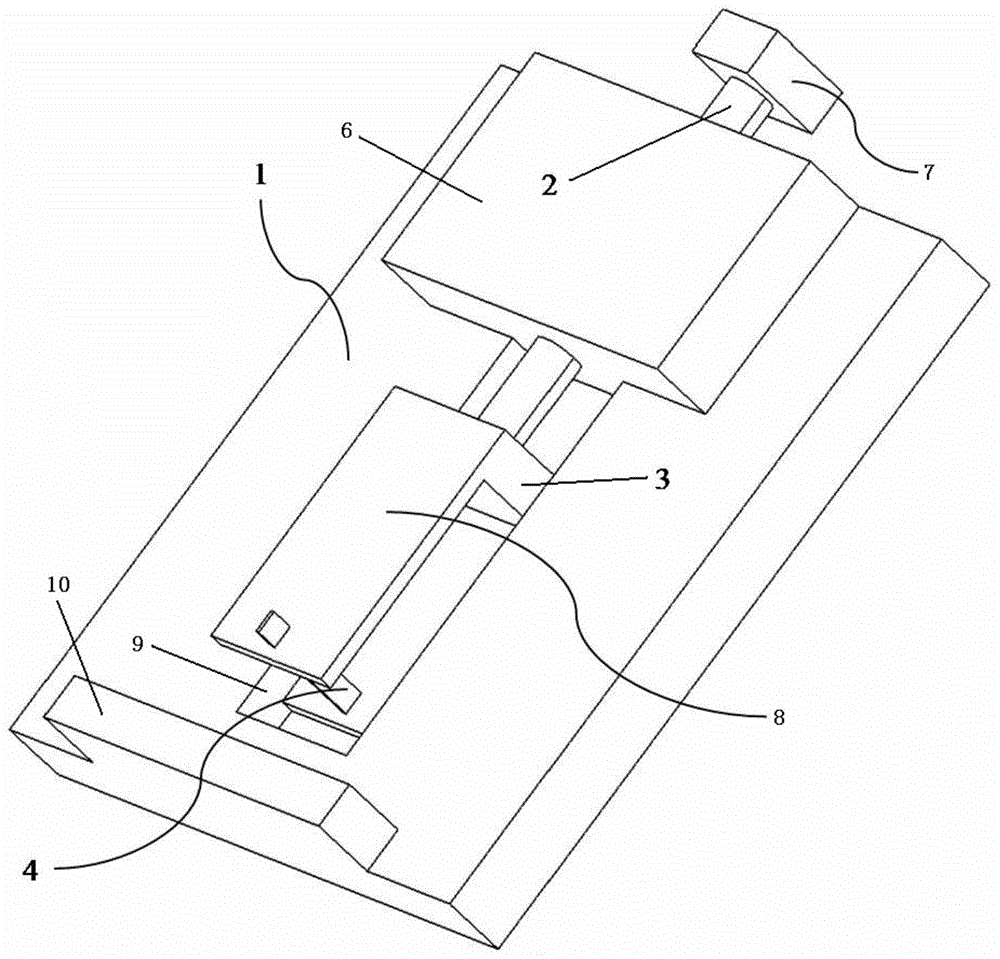

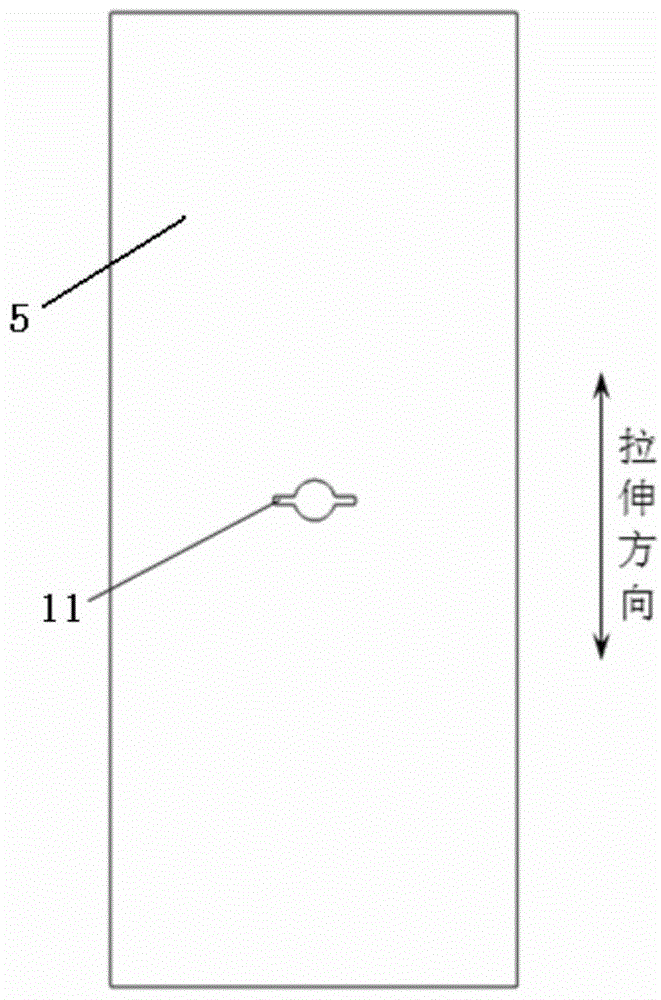

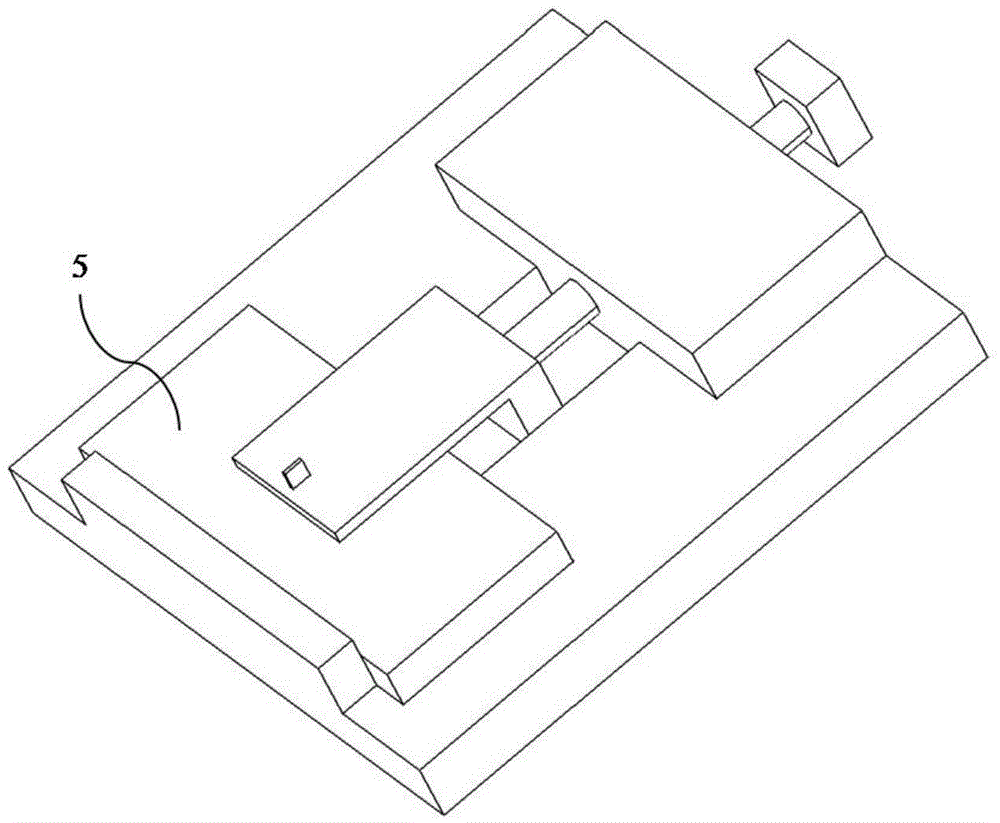

[0011] as attached Figure 1~2 As shown, the prefabricated crack device for the fracture toughness test of non-metallic materials is characterized in that: the device includes a base 1, and at the rear of the base 1 is a boss 6 with a threaded hole, and the adjusting screw 2 passes through the Threaded hole, the rear end of the adjusting screw 2 is equipped with a rotating handle 7, the front end of the adjusting screw 2 is fixedly connected with the bottom end of the U-shaped knife rest 3, and the side plate 8 of the U-shaped knife rest 3 is embedded in the transverse groove 9 of the base 1 Among them, the U-shaped knife rest 3 can move back and forth along the transverse groove 9, and the blade 4 for prefabricating cracks is installed between the two side plates 8 of the open front end of the U-shaped knife rest 3. The cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com