Multi-target hierarchical prediction control method based on continuous stirred tank reactor

A stirring reactor and predictive control technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of complex nonlinear model, difficulty in guaranteeing the priority of optimization objective function, unfavorable factory production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

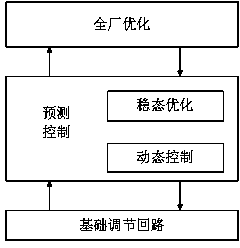

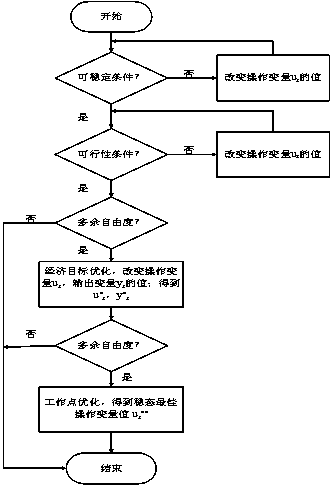

[0064] The present invention is based on the multi-objective hierarchical predictive control method of continuous stirring reactor, such as figure 1 , in conjunction with specific embodiments and accompanying drawings to describe in detail, comprising the following steps:

[0065] (1) Collect the initial values of state variable x(t) and input variable u(t), the state variable x(t) includes outlet concentration, reactor volume, reactor temperature, and the input variable u(t) includes The heat transfer between the reactors and the valve position at the outlet of the reactor; as shown in Table 1 and Table 2.

[0066] Table 1

[0067] State variables

initial value

A Reactor Volume V1

200

A reaction kettle discharge product concentration q1

0.0357

A Reactor temperature T1

446.471

B Reactor Volume V2

100

B reaction kettle discharge product concentration q2

0.0018

B reactor temperature T2

453.2585

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com