Positive aluminum foil conductive agent for lithium ion battery and preparation method of positive aluminum foil conductive agent

A lithium-ion battery and conductive agent technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor current collector adhesion, poor processing performance, low electrical conductivity, etc., achieve good chemical stability, improve The effect of high adhesion and charge-discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

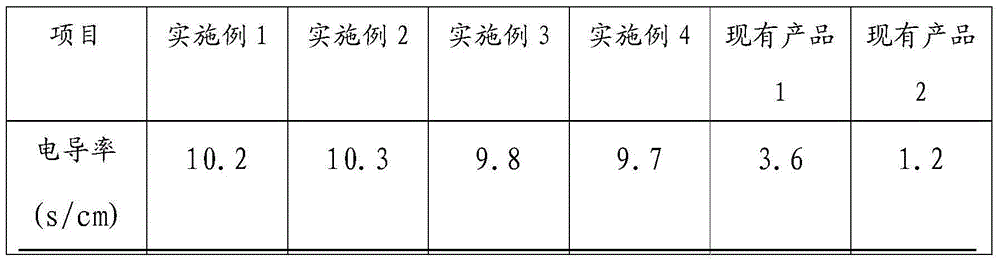

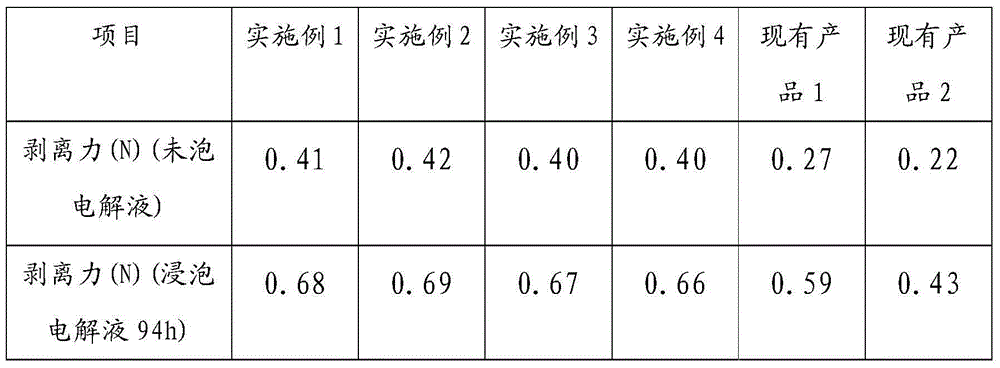

Examples

Embodiment 1

[0033] Lithium-ion battery positive electrode aluminum foil conductive agent is prepared from the following raw materials by weight percentage: graphite 16.0%, conductive carbon black 5.0%, modified water-based epoxy resin 5.0%, butadiene styrene polymer 23.0%, carboxylate Sodium methylcellulose 0.5%, sodium polyacrylate 0.3%, peach gum 2.6%, 2-amino-2-methyl-1-propanol 0.3%, polyoxyethylene sorbitan monolaurate 0.3%, sub Sodium methyl bis-naphthalene sulfonate 0.6%, polyvinylpyrrolidone 0.3%, ammonia water 5.0%, and deionized water in the balance.

[0034] The preparation method of lithium-ion battery positive electrode aluminum foil conductive agent is characterized in that, comprises the steps:

[0035] 1) Add graphite, sodium carboxymethyl cellulose, peach gum, and ammonia water in sequence according to the formula ratio, and stir until uniform with a mixer to obtain the first graphite slurry; the stirring time is 1-3 hours.

[0036] 2) Grinding the first graphite slurry ...

Embodiment 2

[0042] The characteristics of this embodiment are: lithium-ion battery positive electrode aluminum foil conductive agent is prepared from the following raw materials by weight percentage: graphite 20.0%, conductive carbon black 3.5%, modified water-based epoxy resin 10.0%, butadiene benzene Ethylene polymer 18.0%, sodium carboxymethylcellulose 1.3%, sodium polyacrylate 0.08%, peach gum 6.0%, 2-amino-2-methyl-1-propanol 0.65%, polyoxyethylene sorbitan mono 0.3% of laurate, 0.6% of sodium methylene bis-naphthalene sulfonate, 0.6% of polyvinylpyrrolidone, 3.0% of ammonia water, and the balance is deionized water.

[0043] The preparation method of the lithium ion battery positive electrode aluminum foil conductive agent described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0045] The characteristics of this embodiment are: lithium-ion battery positive electrode aluminum foil conductive agent is prepared from the following raw materials by weight percentage: graphite 15.0%, conductive carbon black 3.0%, modified water-based epoxy resin 5.0%, butadiene benzene Ethylene polymer 11.0%, sodium carboxymethylcellulose 0.1%, sodium polyacrylate 0.05%, peach gum 2.0%, 2-amino-2-methyl-1-propanol 0.3%, polyoxyethylene sorbitan mono 0.05% of laurate, 0.2% of polyvinylpyrrolidone, 0.3% of sodium methylene bis-naphthalene sulfonate, 2.0% of ammonia water, and the balance is deionized water.

[0046] The preparation method of the lithium ion battery positive electrode aluminum foil conductive agent described in this embodiment is the same as that in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap