Medlar picking machine

A technology of picking machine and wolfberry, applied in the direction of picking machine, harvester, agricultural machinery and implements, etc., can solve the problems of difficult fruit picking, fruit damage, limited efficiency improvement, etc. The effect of increasing the picking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be described in detail below with reference to the accompanying drawings and examples.

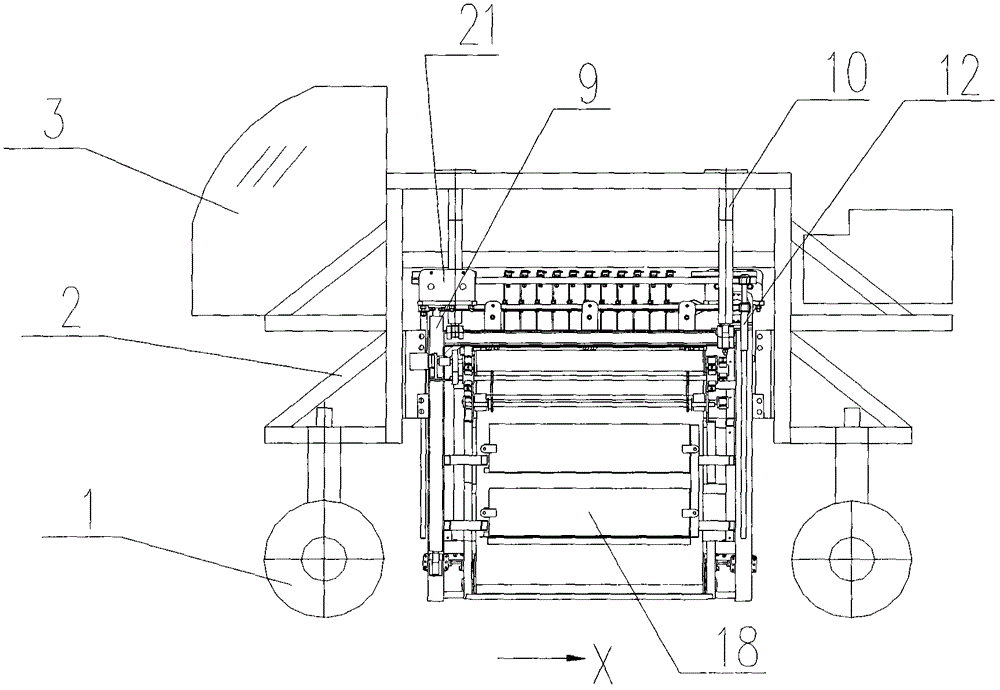

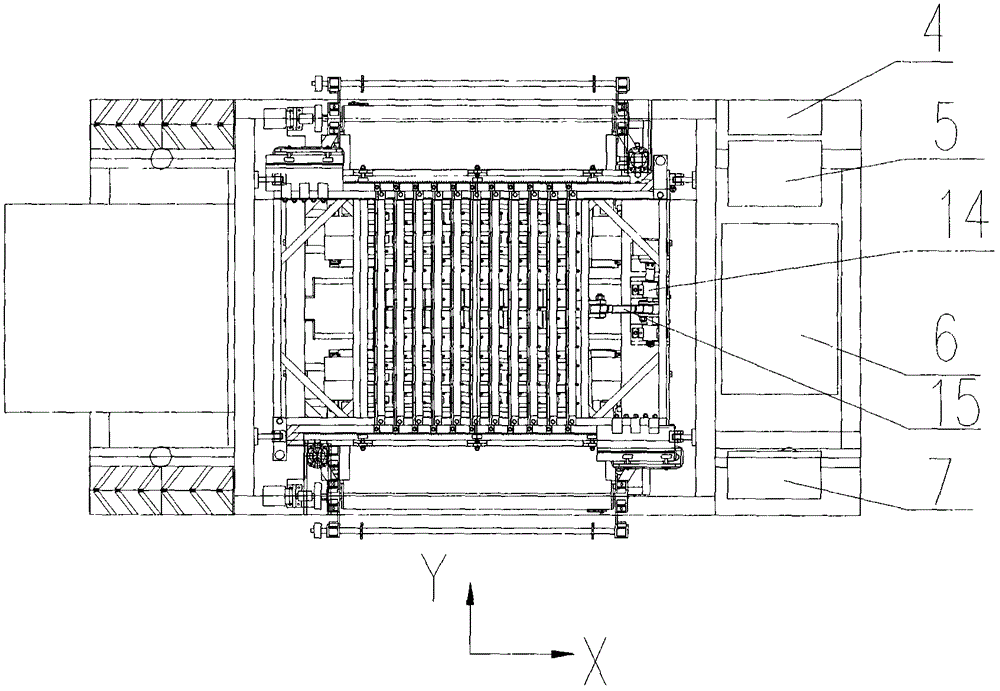

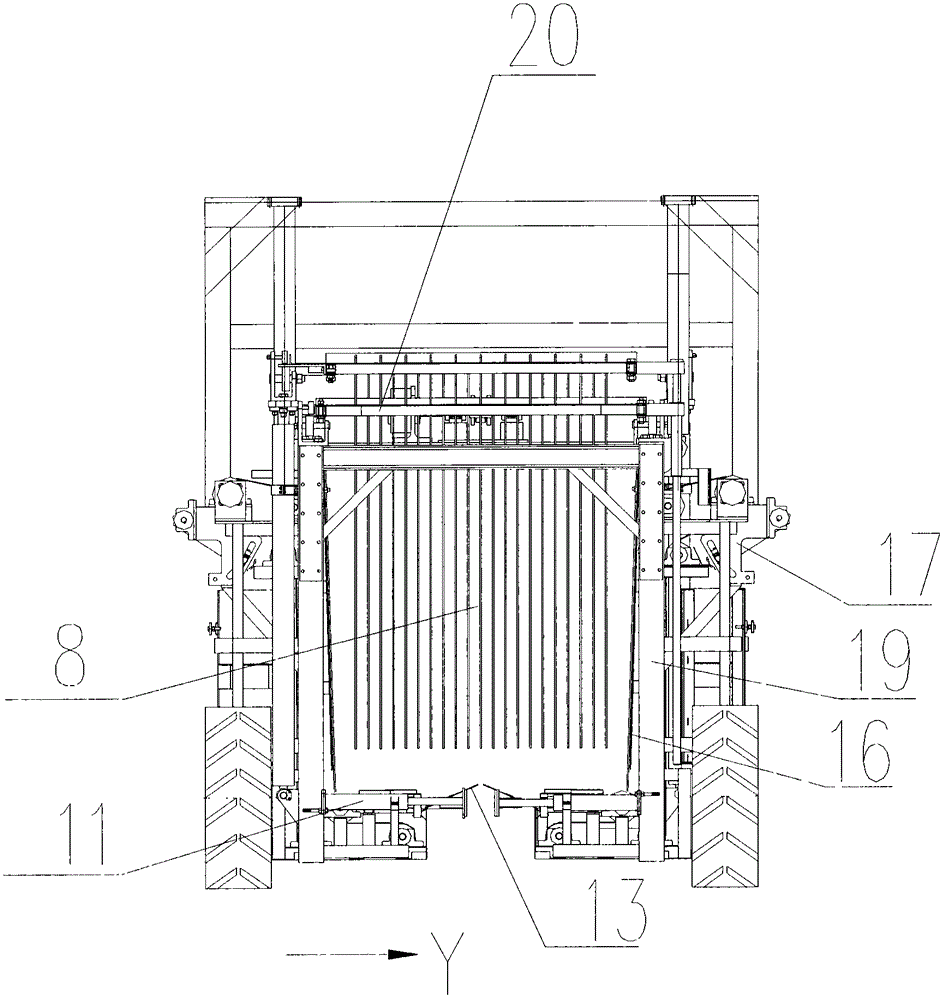

[0029] The invention provides a wolfberry picking machine, see the attached Figure 1-5 , including: bracket assembly, acquisition assembly and vibration assembly;

[0030] The bracket assembly includes: wheel 1, bracket A2, cockpit 3, diesel tank 4, walking hydraulic control module 5, engine 6, picking hydraulic control module 7 and lifting cylinder 10; there are four wheels 1; the bracket A2 is a square frame composed of connecting rods; four wheels 1 are installed on the four corners of the bottom surface of the bracket A2, and the direction along the movement of the wheels 1 is the X axis, and the direction perpendicular to the movement of the wheels 1 is the Y axis; the cockpit 3 is fixed At the upper end of the side of the bracket A2 along the Y-axis direction, and located in the middle of the two wheels 1, the diesel tank 4, the traveling hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com