Special concentrated feed for Muslim mutton in later fattening period

A technology of concentrated feed in the late stage of fattening, applied in animal feed, animal feed, application, etc., can solve problems such as economic losses of farm households, achieve the effects of reducing feed cost, increasing economic benefits, and increasing the growth rate of mutton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

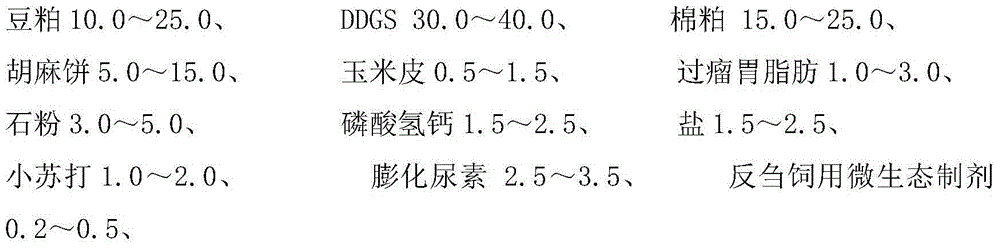

Embodiment 1

[0039] Expanded urea:

[0040] The urea, corn husk and DDGS are prepared according to the weight ratio of 40:50:10 and then prepared by the puffing process. The specific process is as follows:

[0041] 1) Grind urea, corn bran and DDGS into 2.0mm-3.0mm fine powder, and mix them in proportion;

[0042] 2) Put it into the puffing extrusion machine, when the temperature in the machine cavity reaches 110℃~130℃, the modulation time is 30~40s;

[0043] 3) Instantly extrude from the die hole of the center outlet;

[0044] 4) Control the diameter of the die hole to 8mm, and the discharge speed to 1t / h.

[0045] Concentrated feed:

[0046] 20.0Kg soybean meal, 33.0Kg DDGS, 20.0Kg cotton meal, 10.0Kg flax cake, 0.5Kg corn husk, 1.0Kg rumen fat, 4.0Kg stone powder, 2.0Kg calcium hydrogen phosphate, 2.0Kg salt, 1.0Kg baking soda, expanded urea 3.0Kg, probiotics for ruminant feeding 0.3Kg, Dabeinong mutton sheep special premix SH11-203.2Kg.

[0047] Weigh various raw materials accordi...

Embodiment 2

[0049] Expanded urea:

[0050] The urea, corn hulls and DDGS are prepared according to the weight ratio of 30:60:25 and then prepared by the puffing process, and the specific process is the same as that in Example 1.

[0051] Concentrated feed:

[0052] 25.0Kg soybean meal, 30.0Kg DDGS, 18.0Kg cotton meal, 9.5Kg flax cake, 1.0Kg corn husk, 1.2Kg rumen fat, 3.7Kg stone powder, 2.2Kg calcium hydrogen phosphate, 2.0Kg salt, 1.5Kg baking soda, expanded urea 2.5Kg, probiotics for ruminant feeding 0.2Kg, special premix SH11-203.2Kg for Dabeinong mutton.

[0053] Weigh various raw materials according to the above weight ratio: all solid raw materials are crushed into 2.5mm fine powder, and mixed.

Embodiment 3

[0055] Extruded feed:

[0056] The urea, corn hulls and DDGS are prepared according to the weight ratio of 45:40:20 and then prepared by the puffing process, and the specific process is the same as that of Example 1.

[0057] Concentrated feed:

[0058]10.0Kg soybean meal, 40.0Kg DDGS, 15.0Kg cotton meal, 14.0Kg flax cake, 1.5Kg corn husk, 2.0Kg rumen fat, 4.0Kg stone powder, 1.8Kg calcium hydrogen phosphate, 2.0Kg salt, 1.8Kg baking soda, expanded urea 3.5Kg, probiotics for ruminant feeding 0.4Kg, Dabeinong mutton special premix SH11-204Kg.

[0059] Weigh various raw materials according to the above weight ratio: all solid raw materials are crushed into 2.5mm fine powder, and mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com