Fermentation pool for brewing soy sauce

A technology for brewing soy sauce and fermentation tank, which is applied in the field of brewing soy sauce. It can solve the problems of increasing the contact area between heat preservation water and fermentation tank, poor heat preservation effect, etc., and achieve the effect of overcoming large temperature difference in heat preservation, good temperature difference effect, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

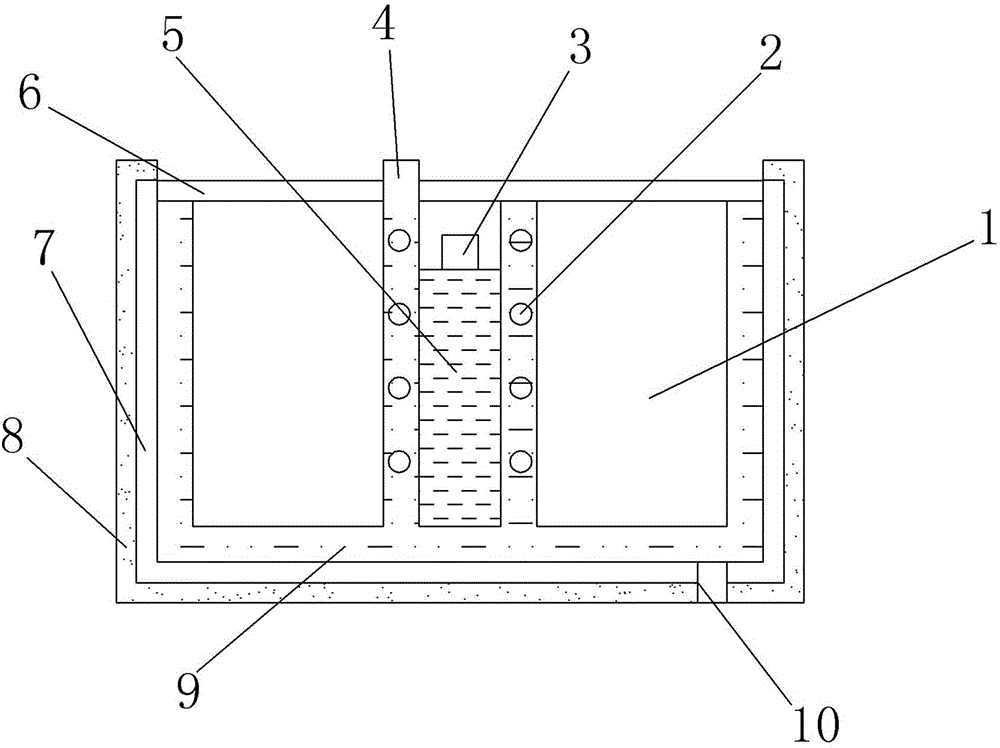

[0013] like figure 1 As shown, the present invention provides a fermentation tank for brewing soy sauce. The pool 1 and the heat preservation pool 5 are also provided with a heat preservation passage 9, the heat preservation passage 9 is provided with a water inlet 4 at the top of the fermentation tank 1, and a water outlet 10 is provided at the bottom, and an electric heating tube 2 is arranged in the heat preservation passage 9, and the electric heating pipe 2 is connected to There is power. Also be provided with one deck anti-seepage layer 7 on the inwall of fermenting tank 1, cover plate 6 is movably connected on the top of fermenting tank 1, all be provided with reinforcing steel bar inside the wall of fermenting tank 1 and heat preservation pool 5, in addition, in the anti-seepage A reinforced concrete layer 8 is arranged outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com