Vacuum degassing tank

A vacuum degassing and tank technology, which is applied in the direction of liquid degassing, chemical instruments and methods, separation methods, etc., can solve the problems of affecting the degassing effect of degassing tanks, affecting the working quality of vacuum pumps, and wasting heat energy, etc., to improve the market Competitiveness, prolonging the service life of equipment, and improving degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

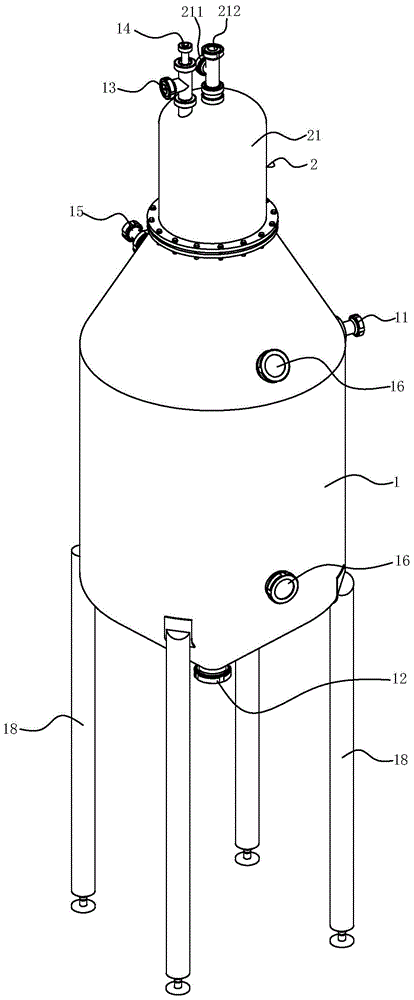

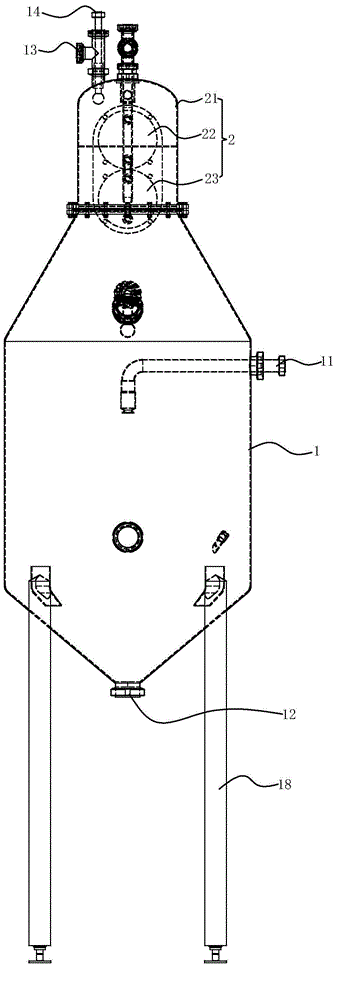

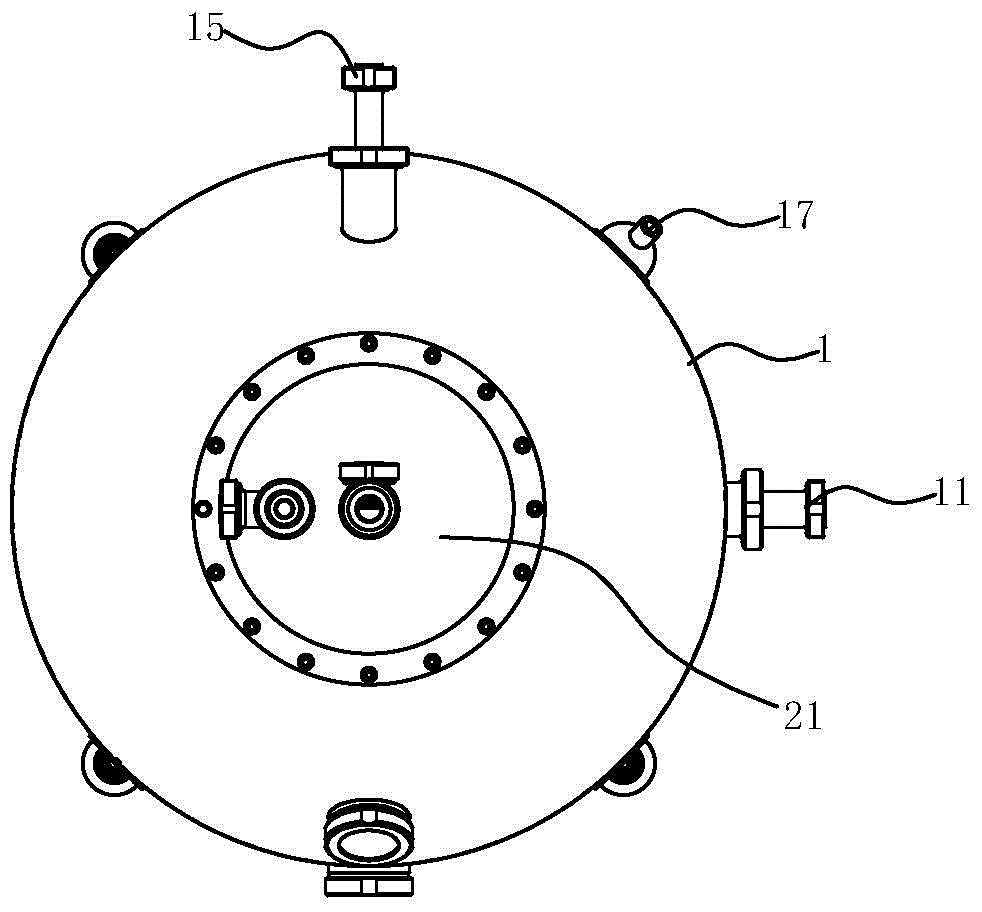

[0026] See Figure 1-5 Shown is a vacuum degassing tank, which includes a tank body 1 , a feed liquid inlet 11 and a feed liquid outlet 12 arranged on the tank body 1 , and a detachable condenser assembly 2 .

[0027] The condenser assembly 2 is arranged on the upper part of the tank body 1. After boiling, the feed liquid evaporates and rises to the top of the tank body 1, and enters the condenser assembly 2 for condensation in time, which can reduce loss.

[0028] The upper end of the tank 1 is provided with a flange, and the condenser assembly 2 is installed at the flange. The condenser assembly 2 includes: a housing 21 installed on the upper end of the tank 1 and a housing 21 The first heat exchange core 22 and the second heat exchange core 23 are connected in parallel with each other.

[0029] The shell 21 and the upper end of the tank body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com