Thin-wall ring spray protection tool

A technology for protecting tooling and thin-walled rings. It is used in spraying devices, devices that apply liquid to surfaces, coatings, etc. It can solve the problems of spraying dust, poor air circulation, falling off of the inner wall coating of the implicated parts, and unqualified spraying of the parts. and other problems, to achieve the effect of reducing adhesion of paint, considering lightness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

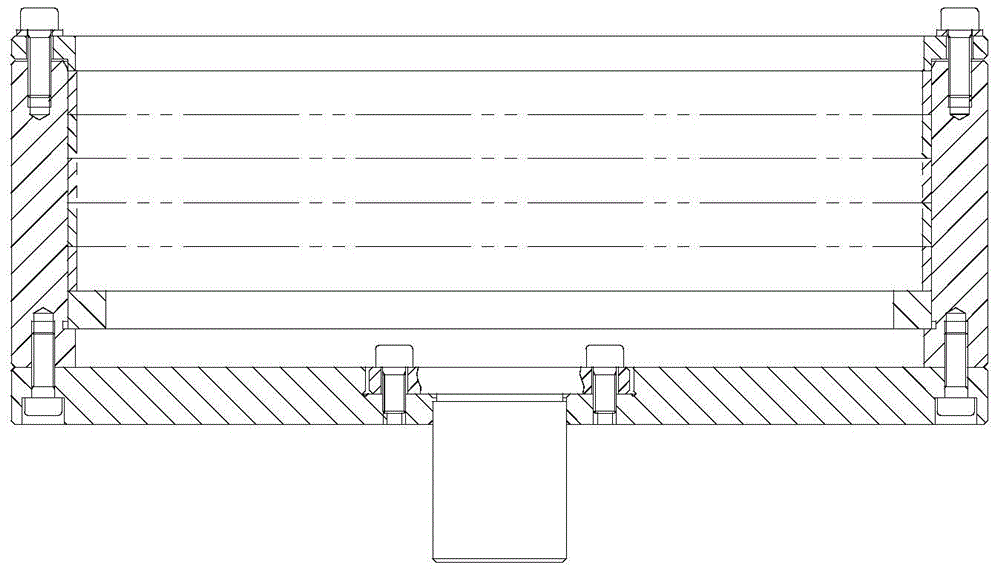

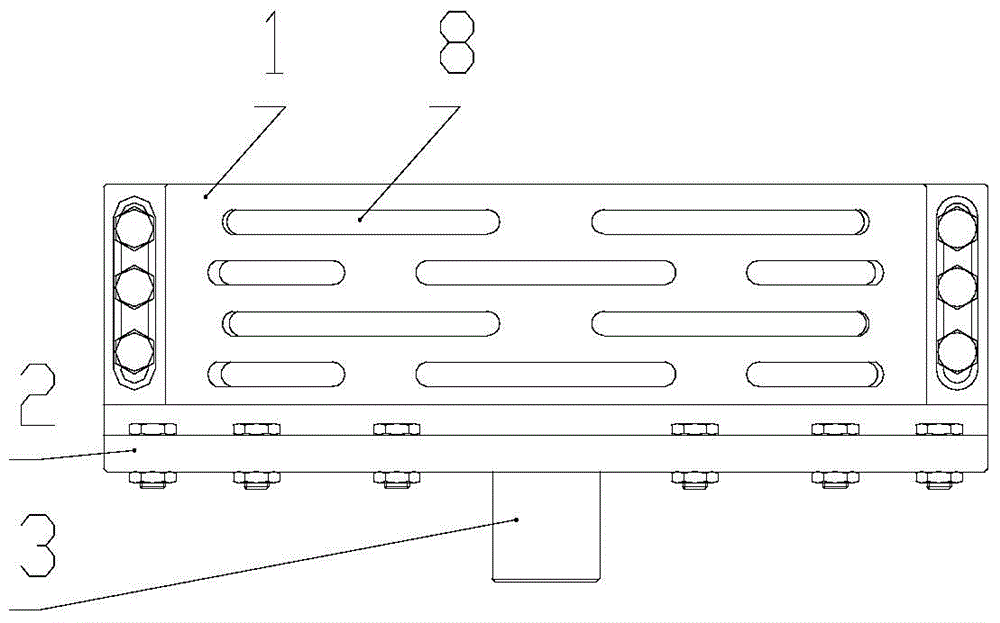

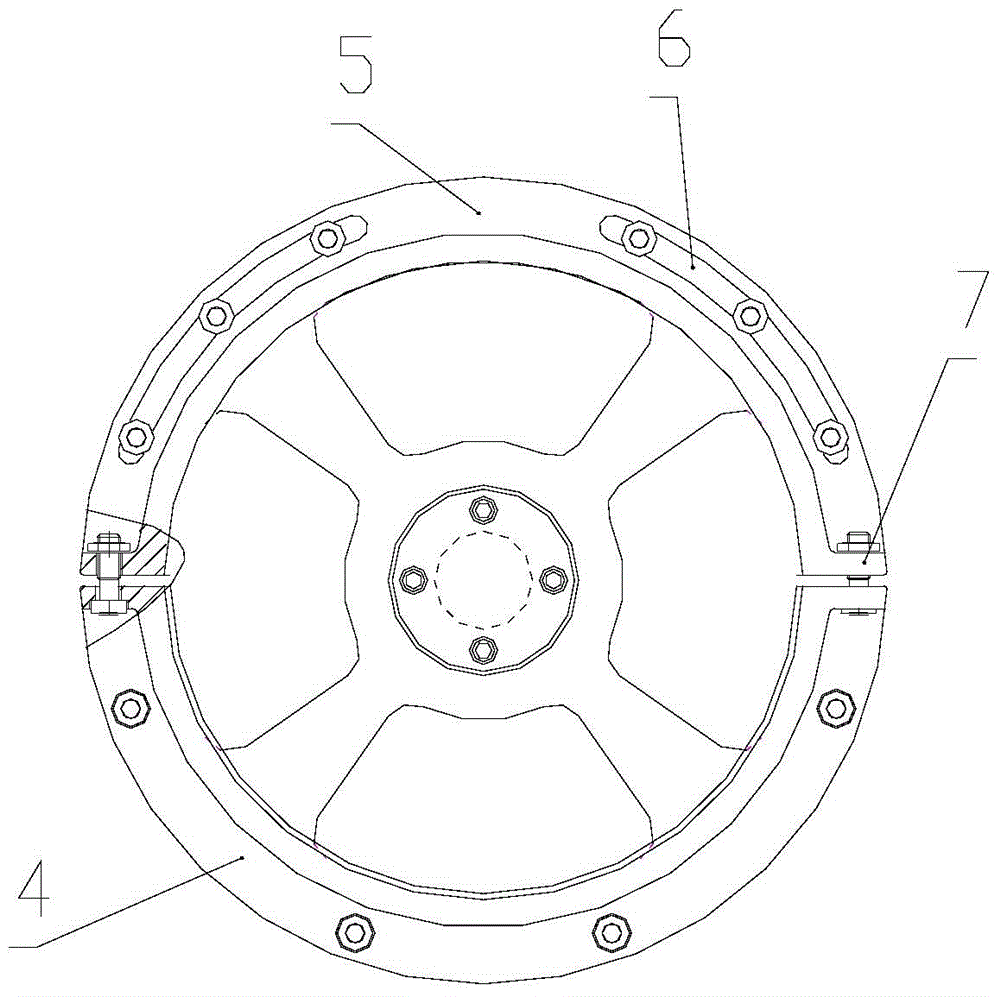

[0010] As shown in the figure, the thin-walled ring spray protection tooling includes a positioning ring 1, a support plate 2, and a mandrel 3. The positioning ring 1 includes two half-rings, fixed and movable, and the fixed half-ring 4 is fixed and installed through the flange edge provided. On the support plate 2, a flange edge is also arranged on the movable half ring 5, and a long screw hole 6 is arranged on the flange edge, and a connecting structure is arranged on the outside of the two half rings and the two half rings can be fixedly connected into one A ring, the inside of the two half-rings is provided with a semi-annular boss structure and when the two half-rings are connected to form a ring, the two semi-annular boss structures form a complete annular boss, the There are multiple bosses, the distance between two adjacent bosses is the width of the part to be sprayed, the two half-rings are also provided with ventilation slots 8, and the mandrel 3 is located at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com