A method for connecting steel sheets and die castings

A die-casting and steel sheet technology, which is applied in the field of metal parts processing, can solve the problems of cumbersome preparation work, increased production costs, and time-consuming, etc., and achieve the effects of reducing production costs, improving connection strength, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

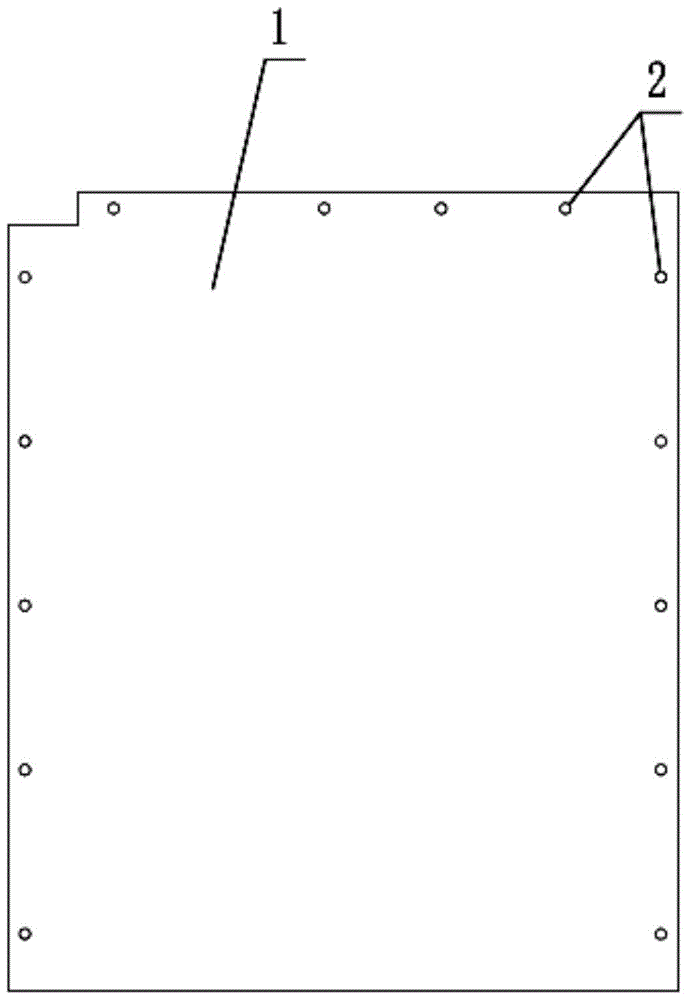

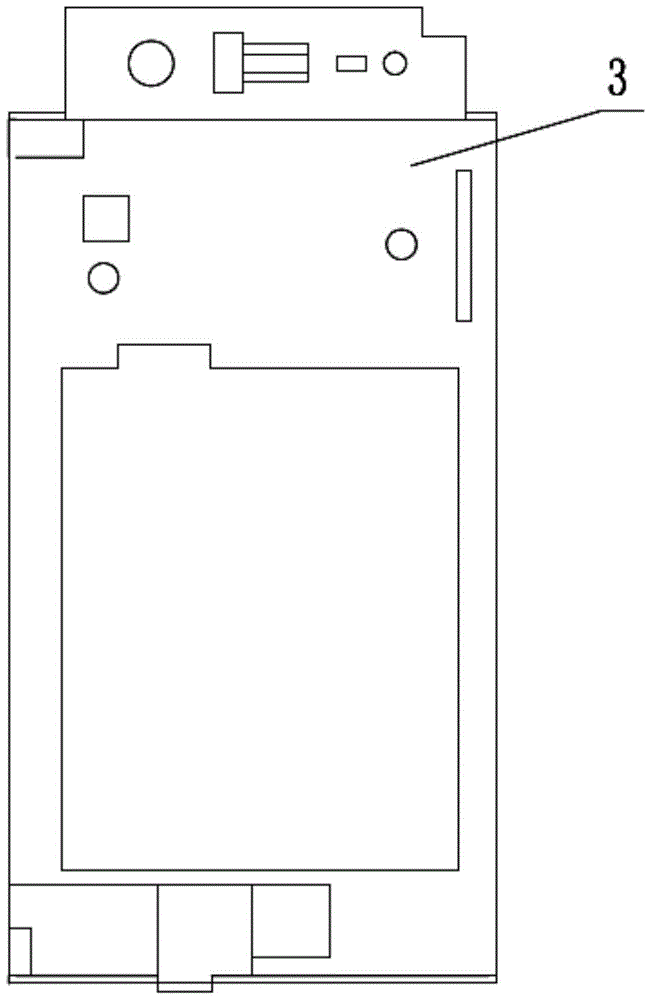

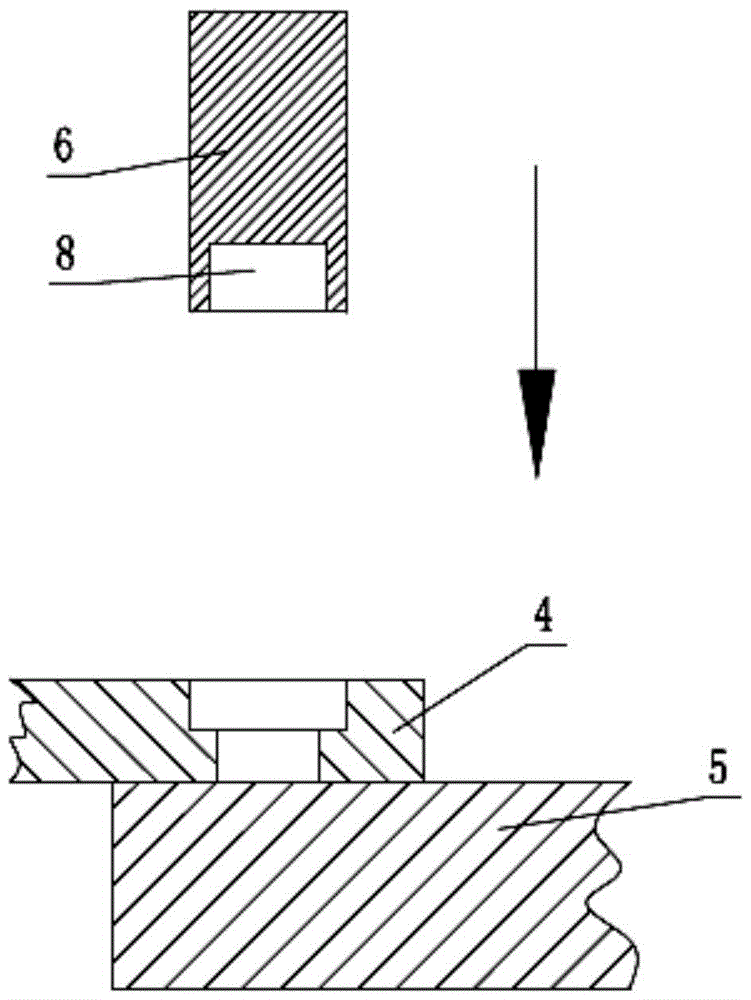

[0038] like Figure 1 to Figure 6 As shown, the present invention is composed of stainless steel sheet 1, mobile phone die-casting plate 3 without connecting through holes and cylindrical concave punch 6 to work together.

[0039] First, place the stainless steel sheet 1 accurately on the top of the mobile phone die-casting plate 3, and align the connecting through hole 2 of the stainless steel sheet 1 with the corresponding part of the mobile phone die-casting plate 3; then, apply a vertical downward force to the cylindrical concave punch 6 The stamping force makes the cylindrical concave punch 6 move vertically and downward, with its circumferential surface 9 as the action surface, impacting the connecting local area 4 of the stainless steel sheet and the connecting local area 5 of the die-casting plate of the mobile phone, and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com