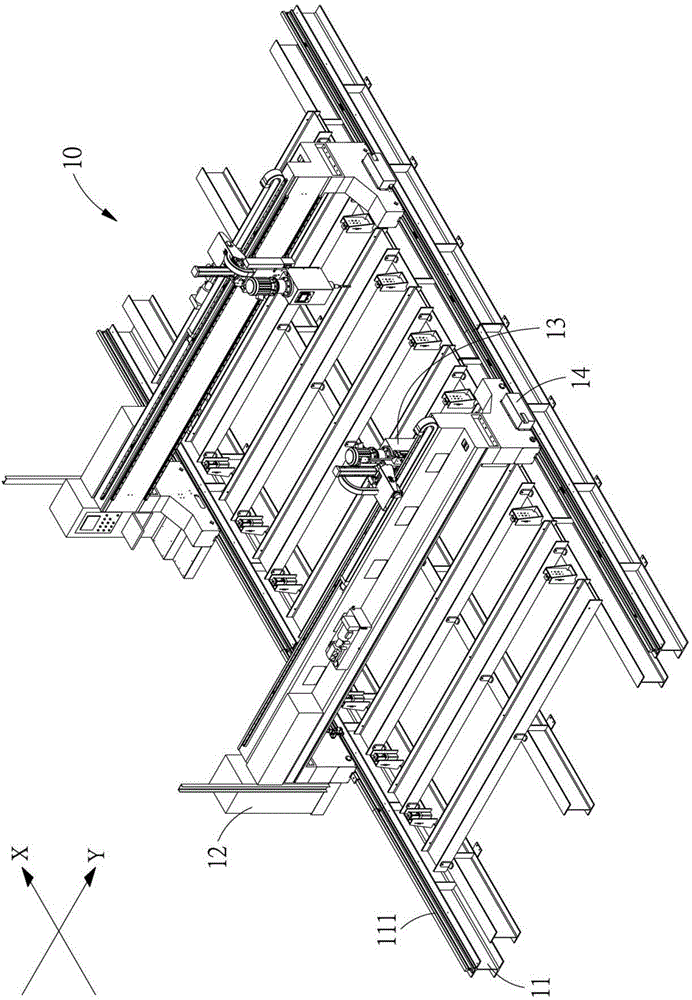

Two-stage displacement type drilling machine

A drilling machine, two-stage technology, used in boring/drilling, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve the problem of high equipment cost, slow command cycle, and displacement of ordinary drilling equipment Insufficient precision and other problems, to achieve the effect of reducing control equipment cost, fast instruction cycle, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

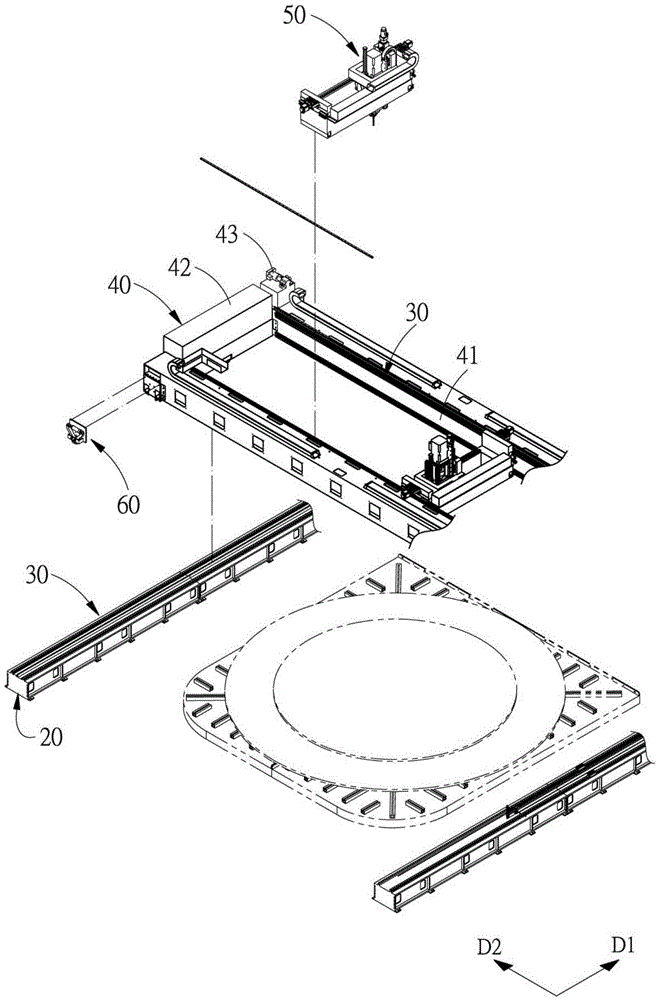

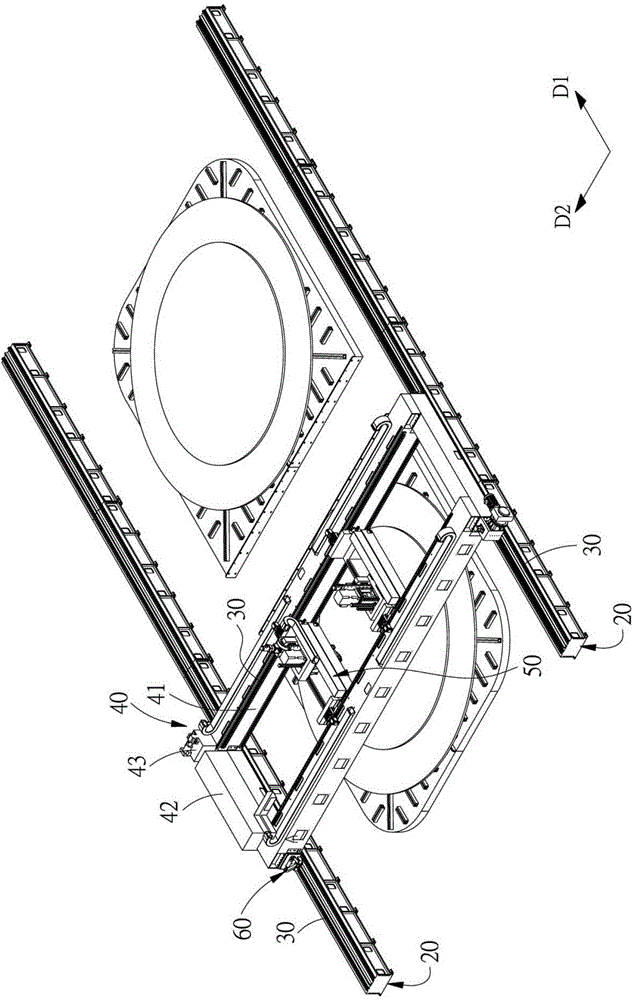

[0033] The preferred embodiment of the drilling machine of the two-stage displacement of the present invention is as follows: Figures 2 to 5 shown, including:

[0034] Two first guide rails 20 are arranged parallel to each other, and each of the first guide rails 20 has two ends. The connection direction of each of the two ends of the first guide rails 20 is defined as the first direction D1, and the direction perpendicular to the first direction D1 is defined as the second direction D2. The first guide rails 20 in this embodiment are linear slide rails;

[0035] A plurality of optical scales 30 are arranged on each of the first guide rails 20 along the first direction D1;

[0036] An equipment platform 40 is slidably arranged on the first guide rail 20 and can be displaced along the first direction D1, and the equipment platform 40 is provided with two opposite second guide rails 41, and each of the second guide rails 41 is arranged along the second direction D2 , and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com