Method and device for automatically adjusting blade clearance of plate shearing machine

An automatic adjustment and shearing machine technology, applied in the direction of automatic control devices, shearing machine accessories, shearing devices, etc., can solve the problems of inability to adjust, troublesome adjustment process, unsatisfactory adjustment accuracy, etc., to solve difficult processing, Good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

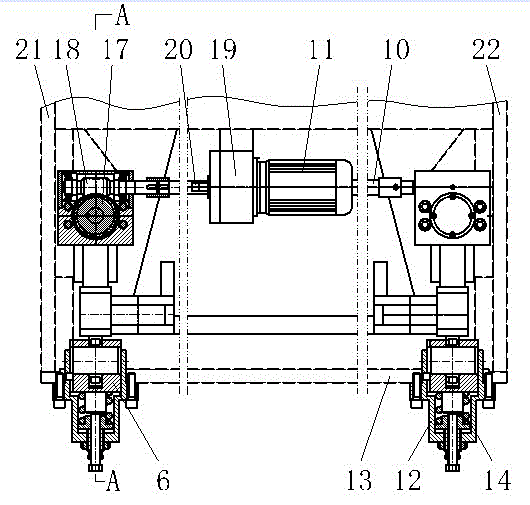

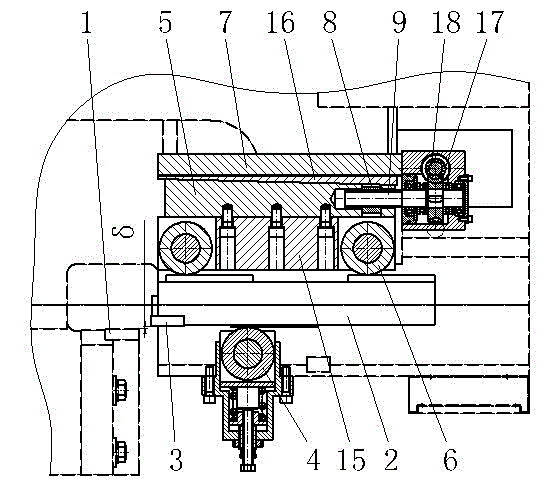

[0019] An automatic adjustment method for the blade gap of a shearing machine, such as figure 1 and figure 2 shown. The method is to set elastic rollers on the front panel of the shearing machine to press the upper knife rest, so that the upper knife rest is close to the rear support; at the same time, a wedge-shaped backing plate is set between the upper knife rest and the rear support, and the wedge-shaped pad is driven by adjusting the motor. The plate slides between the rear support and the upper tool holder to realize the stepless adjustment of the gap δ of the shearing machine blade. The adjusting motor is driven by a control circuit, and the rotation angle of the adjusting motor is converted into an electrical signal by an encoder and fed back to the control circuit. After comparing the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com